There are distinct advantages to the use of modular elevators for parking structures. This is especially true when adding the MEM Elevator System to you next project. Conversely, adding a conventional elevator to a new or existing parking facility can cost hundreds of thousands of dollars. Beyond that the process can take months. The MEM Elevator System is an architectural solution, which effectively deals with these issues, saving you time and money. Those are distinct advantages of the modular elevator and set us apart from other alternatives.

The MEM Elevator System, is a prefabricated the hoistway which is manufactured off-site in a remote location. This allows the modular elevator to be manufactured in the plant simultaneously to the construction of the parking structure.

Unlike conventional elevators, modular elevators don’t need to be an inherent part of the parking structure they are servicing. Instead, they are easily attached to the existing structure. This often is on the exterior of the building without having to share the same foundation.

For an existing parking structure that is adding floors and needs a vertical transportation system, a modular elevator is the ideal solution. It extends the life of the parking facility when adding a modular elevator. You will lose no square footage – all while ensuring accessibility for everyone.

Also, placing the modular elevator on-site before the parking facility is fully built is possible. It can even can be used as the construction elevator – as long as power is available.

See, regulators typically require a temporary construction lift for projects over three stories. The alternative is an elevator to be installed at a job site. A permanent modular elevator can be used to meet these requirements. It then eliminates the need to rent and expense a temporary lift. That in itself demonstrates distinct advantages of the modular elevator.

Additionally, modular construction offers shorter build times; typically 50 to 60 percent less than a traditional on-site construction project. A modular elevator can be up and running before a conventional hoistway is built. This provides an earlier return on investment and lower professional fees.

The two most common vertical transportation solutions used in parking facilities are hydraulic and traction machine roomless (MRL) elevators. Both are available full-sized for commercial use and both are equal in performance and quality.

Hydraulic has the advantage of being easier to install and maintain. This makes them a less expensive choice in the long run. As a result hydro elevators are the recommendation we most often make. They are in use in parking structures between two-to-five stories and are available with holeless-twin or in-ground jacks. Holeless hydraulic elevators use above-ground cylinders and are used in sustainable or cost-sensitive projects with two to three floors. With the holeless elevators you can eliminate the unknowns related to drilling for in-ground jacks.

The in-ground hydraulic system can easily accommodate five stories or even higher. It provides a smooth ride and lower maintenance costs overall.

The traction MRL is an option, that offers little more than the hydraulic units. It is marginally faster (literally seconds) and can achieve higher total travel. However, the additional speed comes with a cost of higher maintenance fees.

It is important for the contractor to work closely with the modular elevator manufacturer. They should be involved when planning and installing a modular elevator for a successful installation. Logistics and timing play an important role in maximizing the financial opportunities that modular elevators afford. The MEM team offers support, coordination and communication in the process.

The first step in the installation process is pouring the concrete elevator pit. The anchor bolt template from MEM is useful for precise positioning. Second, once the elevator is set in place, it is attached to the anchor bolts and verified to be plumb. You now have a fully installed elevator.

Next, the fully-assembled modular equipment room is set into place. This installation process is usually completed by lunch time. No kidding.

After the elevator is set, electrical, fire and phone services are provided and final adjustments are completed. Upon inspection and approval by the appropriate jurisdictions, the elevator is ready for use in a matter of days.

As you can see modular elevators offer many benefits over conventional elevators. For all low and mid-rise applications in new and retrofit construction we are the preferred solution.

Lastly, we can customize the ready-to-use MEM Elevator System. In that way we can meet the needs of any project. And the end results are indistinguishable from conventional construction. They are also available with vandal resistant features because we all know a parking garage elevator needs to be tough. One thing for sure there are distinct advantages of the modular elevator for the parking industry.

We hope we have laid out a good argument for the advantages of the modular elevator for parking structures. So if you have any interest contact us at any time. We will help you think though potential uses. If you have a project in mind, click the Fast Track button below. You will be provided a thumbnail number and receive additional information. If you would like to see how we create the elevator, you can register for a Live Virtual Tour. Or come visit our factory in person. We would love to show off a bit.

Modular Timeline the Secret of Success. When it comes to success in construction it usually boils down to getting the job done on time. You can have the greatest plans, design or ideas, but if not executed in a timely fashion the value diminishes.

Construction projects outside of infrastructure generally are built for occupation. Any delay of occupancy is money out of the pocket of the owner or investor. That means pressure on everyone and makes time extremely important. That is the primary reason for success of modular and the modular timeline.

This striking revelation occurred to me when speaking with a building owner. He was checking up on a project with the project’s manager. The build in question was the first time this particular owner had sunk time and money into a modular project. Needless to say he was a bit apprehensive. However, after getting a breakdown of the progress he was amazed.

He claimed the modular elevator alone made him a million dollars based on faster occupancy. That may have been an exaggeration. However, the smile on his face when he said it, made it more than convincing to me.

See, he was long in the tooth so to say in the traditional construction industry. As such he was filled with doubt regarding timelines. That doubt bled over to concerns regarding the completion date promises of the modular companies employed. His feeling of skepticism was well warranted based solely on his background in the traditional construction trades. He became numb to the habits of contractors. They make promises and then excuses and then more promises as they face delay upon delay. He expected nothing less with a modular timeline on the project. But to his pleasant surprise the timeline was kept and ancillary benefits began to pop up.

So what is the modular timeline compared to that of traditional building and why does it matter?

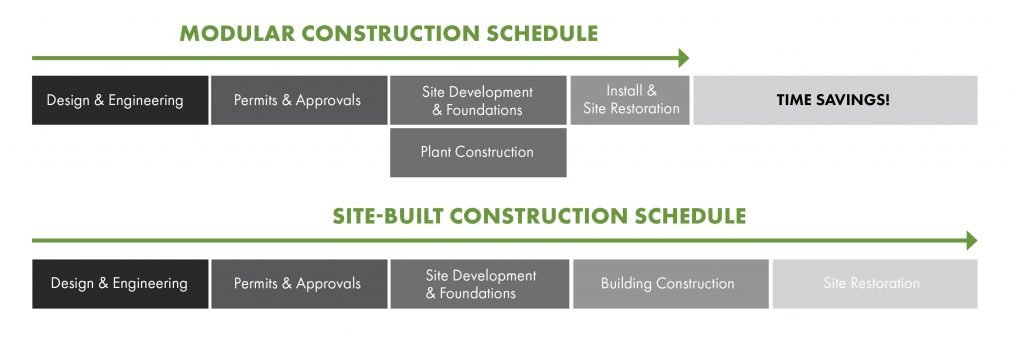

I have used this chart a number of times from the Modular Building Institute. The institute and their entire staff are a great center for information and knowledge regarding modular construction.

Want to dive deeper? I would highly recommend that anyone curious at all should attend their upcoming World of Modular convention. It is in San Antonio, Texas – April 25-28. We will be there in person for additional questions about modular in general and modular elevators.

Back to the timeline graph. It clearly demonstrates the time savings overall for most projects as there is multitasking employed to take advantage of off-site manufacturing. When modular units are built in factories, the time is simply shortened. But what is not incorporated in this chart are the ancillary time savings and benefits.

The secret of success of the modular timeline is slowly, but steadily and surely getting out. More and more builders and building owners are taking the plunge. They are exploring what modular has to offer and how the modular timeline can be a huge benefit.

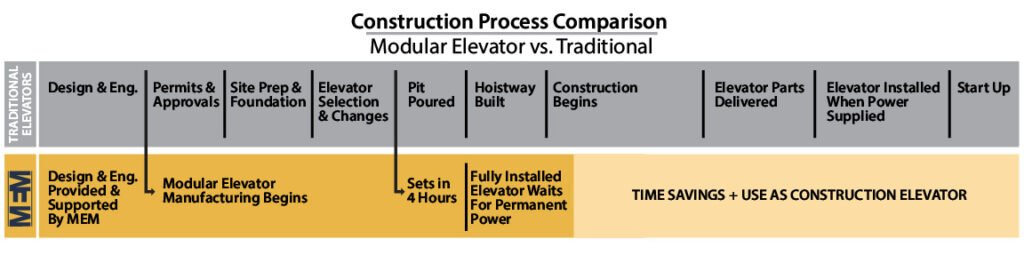

But what about the timeline for modular elevators? Is that as beneficial? The answer simply is yes. The MEM Elevator System is beneficial for the whole project and the results are stunning especially when taken of advantage of in full. Can you imagine how your project would change if you could determine when your fully installed elevator arrives? Then started up in less than a week? Or realizing it goes in so fast it often doubles as the construction elevator on the job? That is a game changer, especially in current times where every penny counts. Take a look at the timeline below.

So now is the time to act if you have any questions about modular elevator or the MEM Elevator System. If you are the least bit curious about Modular Elevator Manufacturing just click the button below. You can get a LIVE VIRTUAL TOUR of our factory. We will pull back the curtain and let you look at our process and how we are leading the modular and elevator revolution.

Do you have a project in mind? To get thumbnail numbers to consider, just click the Fast Track Quote button below. We will be in touch in less than 24 hours. At that time we will give you an idea of how your project will be improved and your investment. You will also find out what it takes to make a change for the better.

I just finished writing a great blog about how Modular Elevator Manufacturing (MEM) is in complete in support of the Modular Building Institute (MBI). Also, included is how we support the modular building industry as a whole and promote the benefits of modular construction. We are even going to the MBI annual convention (see more below)! Then I realized that many could confuse our support with use of our elevators. To be clear and to set the record straight, our MEM Elevator System is compatible with any structure type.

The ability to be compatible, depending on the height, is that MEM elevators are designed to be self-supporting. That means they can be place on the interior or exterior of buildings. Regardless of the construction method used MEM is a fit. Everything from post-and-beam construction to heavy steel framing can use a modular elevator. Even concrete structures can and do incorporate modular components, including the MEM System.

In real terms there is no difference in the use or components in a traditional or a modular system. Our commercial quality elevators are just that, high quality. Modular is just superior. The MEM System provides a fast, high-quality solution that allows you to decide when the unit arrives. When you need it, it is delivered. An elevator shaft lowers into place with a factory installed elevator inside and ready for start up.

Another application that traditional elevators really struggle with are when it comes to retrofit projects. They are a piece of cake for us. Modular elevators are used in additions to structures, exteriors of existing buildings, stadiums and also in the center of existing buildings. And, it is not as hard as it sounds. The good news is that we have had decades of experience. With our help you can determine the best way to place the elevator regardless of the structure type. To assist we will not only provide you with drag and drop drawings, and engineered plans but expert advice. With our system and our help you will accomplish your goals for your project.

Now let’s be clear there are some limitations. MEM elevators are engineered for low and mid-rise applications. Also, depending on the location of the build, there may be some issues with crane use or getting under bridges. But, those are usually minor problems and usually we find ways to circumvent almost any challenge. Here’s an example.

So is the MEM Elevator System perfect for modular building? You bet. But, our elevators are utilized for almost every structure as well.

If you want to find out more about our system you can come and see us at World of Modular. We would be glad to speak with you about the benefits of modular and how our elevators are leading a revolution in construction. This year the conference is in San Antonio, Texas – April 25-28, 2022. If you go (and we highly recommend it) make sure and stop by booth #4. There you can discuss the elevator revolution with our national territory manager Ken Grider.

He will be able to answer any questions you may have and give you a thumbnail price on the spot. If you just can’t wait for the show, you can contact us below for a Fast Track Quote. This quick quote will give you all the pricing information you need to begin your project. You can also sign up for a LIVE VIRTUAL TOUR of our production facility. During the tour you will see how we produce the highest quality modular elevator in the industry. We will take any and all questions about MEM while we show you what we do. Find out how we are taking the elevator industry higher.

Well our full name is Modular Elevator Manufacturing (MEM). We have been in the modular and elevator business for around thirty years and as a result the modular industry is very important to us. We see modular as more than just another way to build. It is a continuing and growing methodology that has forced needed change into the construction industry and elevator industry. It has challenged the status quo with better, smarter, safer and faster ways of producing everything from homes to commercial buildings. This approach has resulted in a revolution that we are proud to be part of where there is more accountability and better processes.

For instance with the MEM Elevator System a fully-installed, commercial elevator is placed in hours and started up in a week. It is incredible and something traditional construction cannot accomplish. Our high-quality system goes in so fast that it is often used as the construction hoist to save even more money on projects.

With that said, leading the charge in the revolution towards better building is the Modular Building Institute (MBI). No doubt as they say, they are “the voice of commercial modular construction”! Their mission is to expand the use of offsite and modular construction through innovative construction practices, outreach and education. They do a fantastic job at fulfilling that mission.

So, if you are a modular producer in the construction industry you should be a part of that organization. We are at Modular Elevator Manufacturing. But more than that if you have any questions about modular, MBI and MEM regarding elevators are experts.

To show off a little bit each year MBI has an annual convention called appropriately the World of Modular. This year it is in San Antonio, Texas – April 25-28, 2022. So, if you are not a modular company but are the least bit curious about the modular industry, I would highly recommend attendance. You will find the leaders of the modular business there discussing alternatives to conventional construction and how modular building continues to grow and change the way projects are completed. It is a place to network, exchange ideas, learn from experts and discuss issues.

At MEM we see joining MBI or attending World of Modular as the first step in joining a revolution of better building and higher quality practices that is changing the world of construction. We look forward to seeing you at the show. Make sure and stop by booth #4 and discuss the elevator and modular revolution with our national territory manager Ken Grider. He will be able to answer any questions and give you a thumbnail price on the spot.

If you just can’t wait for the show, you can contact us below for a Fast Track Quote. This modular elevator quick quote will give you all the pricing information you need to get started. You can also sign up for a LIVE VIRTUAL TOUR. During the tour of our production facility you will see how we produce the highest quality modular elevator in the industry. You can also ask any questions you would like about MEM and our process.

So for some see you in San Antonio or for others, see online live!

Elevator cuts costs as inflation rises. Inflation is not just a term thrown around by the Wall Street crowd or economists. Inflation is very real, very damaging and turns out not transitory (whatever that means). As the January numbers reveal inflation is with us. And an economy does not shift at a whim especially when the all the forces are aligned for inflation and the social psychology for it has set in. The ripples are felt throughout the nation in every home and every sector.

That is especially true in the construction industry. We are engage in long-term commitments and obligations with slim margins. That puts more pressure as we build, meet payroll and see operating costs explode. Suddenly, we grasp for every potential savings available by trimming general costs and seeking alternatives. Surprisingly, the elevator cuts costs as inflation rises, but only if you choose the right alternative.

The right alternative is a commercial quality elevator that has a long-term history of success and that can replace the need for a construction elevator on the jobsite. By consolidating the tasks of a permanent elevator and a construction hoist, costs can be significantly reduced. But, only an elevator fully installed at the beginning of the project and ready for start up early on can meet the need.

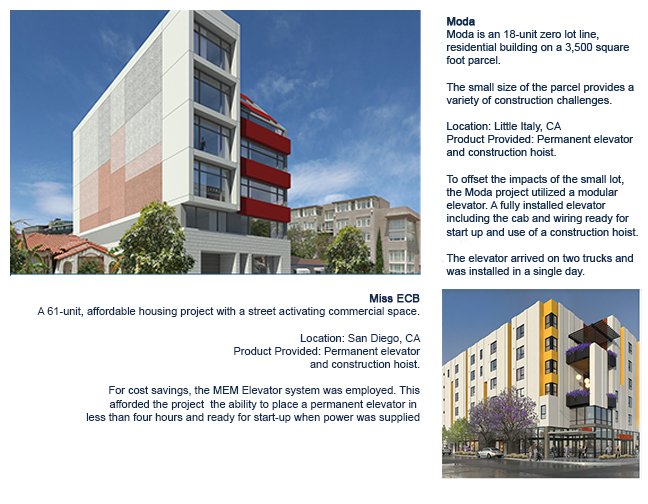

This month’s project spotlight is really several projects, but two in particular that we just finished installing where the permanent elevator doubled as the construction hoist. Not having to employ a construction elevator can reduce costs immensely. This option is not just a way to save during inflationary times, but just smart business.

In both cases the elevator unit or MEM System was in place early in the project. The system can be engineered to be self-supporting, so it is placed and awaits power, set up and inspection. The set up portion of the project is usually less than a week in total hours. This makes it not only plausible to save significantly, but a certainty of reducing costs.

The Miss ECB project fully demonstrates the time and costs savings. As you can see it operates just like any other construction hoist with a set call box for access. Finish protection is key. Protective panels and wraps are in place during the build. You can also see that it is not a project dependent on any one type of construction method. the MEM System is at home in modular construction to stick built applications.

You can see there are two sections as pictured above. They are stackable units that make up the hoistway. The entire process took less than four hours to set. As a result, the fully installed elevator through the MEM System was ready for start up and inspection once power was supplied.

If you want to find out more about how choosing the right elevator cuts costs click below. You can either get a thumbnail budget number for the MEM System for your next project or, your can schedule a live virtual tour. During the tour we will pull back the curtain, so you can see how we produce the best elevator solution for all mid and low-rise applications.

We say elevator revolution a lot. After all it is in our vision and we truly do think we are leading the charge to completely change the elevator industry:

We believe in challenging the status quo…in revolutionizing the “elevator process”. We don’t just think outside the box…we think BEYOND the box.

Of course that is accomplished by moving the elevator process, design, engineering and installation, to the beginning stages of a project.

But what does that mean in real terms? Below is a project that exemplifies “elevator revolution” and how it is a benefit to you. Give it a read and let us know if you want to be part of the elevator revolution.

In this surprising conversation Clay Hubbell talks about savings from a perspective rarely discuss, the true value of taking the elevator off the critical path. He also says what it was like working with MEM for the first time and why more modular elevators maybe in his future.

But first, a little background. The Olive View/UCLA Medical Center project involves constructing a new Restorative Care Village with a Mental Health Wellness Center, Residential Treatment Program and Recuperative Care Center. It is a huge sprawling complex with six elevators.

The purpose of the facility is a needed one. In other words, addressing the pressing need for increased mental health, medical, and homeless support services in local communities is necessary and crucial. The surroundings of the project are impressive. It is purposely placed in quiet hills with nature paths and stunning landscaping and design. The new Restorative Care Village will provide an unparalleled opportunity for mental health and community renewal.

Abbott Construction took on the SWA Architects plan and all the challenges including using modular construction. In many ways it was a test for the modular concept and in particular the MEM elevator system. Due to the size of the project, timelines were crucial and had to be met. The project superintendent, Clay Hubbell was understandably skeptical. He has worked with just about every elevator company and usually sees delays and excuses.

Could the elevators really be taken off the critical path? And would there be any real savings? As the project wraps up we sat down with Hubbell to find out.

“It is hard to put into words what they have meant for this project. Elevators are a challenge when built onsite, but the modular elevators went in with no problems.”

“This is the best elevator team I have ever worked with and I have worked with them all. For instance, they across the board are all about solutions and getting the project done.”

“I can’t say enough about their knowledge, abilities and service. They even worked on Saturdays when we needed them. Great team!”

“Usually when dealing with elevator companies it is a struggle to get personnel when you need them, but working with MEM was an incredibly pleasant and enjoyable experience.”

When was the last time you heard such high praise for an elevator manufacturer or installer?

“The MEM elevator allowed us to move up the whole process. Everyone can can be pushed forward in sequence. Normally the elevator slows everything down. You have framers, rock and tape crews, floor prep, flooring, painters, electricians, sprinklers. They usually come out and work to the elevator openings on each floor. Then they have to stop.”

“With the fully installed modular elevator, all those crews complete their work in sequence. They make one trip out and no call back because the elevator’s openings came finished with door frames already installed.”

“The results, we estimate that saved us $30,000 to $40,000 per opening.”

“Then you have a similar savings on the exterior. Framers, coping metal, parapet work was all done in sequence with no call backs and up charges. The result is tremendous savings.”

Think about the math for a second. With that savings per opening, plus an additional savings on exterior work, that results in MEM elevators saving over a half-million dollars on this project. Why consider anyone else?

“MEM has an incredibly clean operation. We visited the factory for a tour and it’s impressive. Tom (Shield – President) and his team led us on the tour and then answered all of our questions.”

“The entire process was extremely smooth. The dedicated MEM project manager Tim Dolan even consulted with the inspectors before hand to iron out any issues.”

“Usually when dealing with elevator companies it is a struggle to get personnel when you need them, but working with MEM was an incredibly pleasant and enjoyable experience.”

“The delivery and set up time was just like they said. And above all the timeline was met each and every time.”

“Seeing elevators delivered on a flatbed (see a video of the project) and craned into place on time was incredible.”

We are elevator experts in every sense of the word and provide you with a highly experienced project manager. In other words to keep the experience seamless, on track and on time we provide you the help you need.

“We can’t wait for the next project. The incredible savings and ease to work with are unmatched in the elevator industry.”

At the end of the conversation we discussed other applications beyond modular construction. The modular elevator is flexible enough for interior or exterior placement and therefore, can be used in almost any type of construction project for a high-quality solution you can count on.

And of course the feelings are mutual, the Abbot Construction team proved time and time again they are top notch. And we can’t wait for the next one!

Although it seems like high praise, Clay Hubbell’s experience is the norm for people willing to join the elevator revolution. People are tired of the promises and prodding needed when dealing with the conventional elevator industry. When you couple our easy process, experienced and supportive team and money saving product you get a happy and satisfied client.

In conclusion, you can partner with us too! Just click the button below to take a live, virtual tour of our facility. We will honestly answer any questions you may have. You can also give us a few details of a potential project and we can supply you with a Fast Track quote in 24 hours. MEM – Quality Elevators taking you to a higher level.

New York elevator set over the holidays. While most businesses slow down between the last couple weeks of December and January 1, MEM’s schedule picks up. That slow period for most (especially schools) is the perfect time to install a complete elevator in less than four hours with the MEM system. Because they install so quickly there are minimal interruptions that you will find with traditional elevators.

A great example is a project we just set in New York. The Ateres Girls School was a perfect fit for us. The MEM system for the school is an above-ground hydraulic unit with a 25000lb. capacity and 16′ travel distance. It went in easily and smoothly.

That not only speaks to the product and our production team, but also the professionals at Nadler Modular that led the project. They made sure everything was ready and therefore the project went off without a hitch.

A modular project is not a requirement. Even with the elevator placed on the exterior of the building, that is not a always necessary for our elevators. MEM elevators can be placed in any type of construction project. And be placed on the exterior or interior. If you are looking for a vertical transportation solution for any low or mid-rise application we have what you need.

To make MEM a part of your next project just click the link to find out more or get a FAST TRACK QUOTE.

Cold Slows Elevators – An old saying that we use in the Midwest is, “You’re as slow as molasses.” To put a finer point on it we say, “You’re slower than molasses going up hill.” An even further expanded use for the most turtle like folks is, “You’re slower than molasses going up hill, in a snow storm.” As we all know cold slows everything down. And get this, it turns out cold slows elevators too.

I am not saying that cold weather will reduce the functionality of an existing elevator, although it can happen. Usually you press the button and the elevator will show up as expected. But what I am trying to say is that when adding an elevator to a project, cold weather halts the progress of an elevator installation. This happens in a couple of ways.

Traditional elevators require a site built hoistway. In cold temps building one can be a massive challenge. The challenge is both in poured concrete and cmu block construction.

Concrete definitely is a problem child in the winter for shaft or hoistway construction. Pouring concrete is often halted in the colder climates when temps drop in the US and Canada. If it is done anyway the results are often spotty at best. Darrell Bailey from Morton Building, a firm that specializes in metal buildings said, he has seen people try to pour concrete in bad weather with horrible results. He said, “It will freeze and bust. You just can’t pour on frozen ground,” and “that means you are stuck until things thaw out.”

Sometimes warming the ground with black plastic or concrete blankets can work. But if that fails, additional costs must be expended to redo the work. The other option is to change up the mix of the concrete. A chemical accelerator such as calcium chloride can be used. But that does not mean your cold problems are over. The jobsite pour has to be cured for around a week meaning more blankets or black plastic. In extreme cases heating and hoarding is your only option. If you fail, the structure can heave or have chucks of concrete pop off.

With CMU (concrete blocks), you really shouldn’t proceed in a temperature below 20°F or when the the blocks contain frozen moisture, visible ice, or snow on the surface. That stops a lot of building, especially elevator hoistways. I have personally heard of projects where they pushed the envelope and suffered the consequences when they had to tear down the hoistway and start again.

On the other hand, modular building shakes off cold concerns. The work is completed inside a factory. Bad weather? No problem. You do not need to supply a concrete or CMU block elevator shaft on site. The modular elevator includes the hoistway! It doesn’t matter how cold it is outside, our elevator will be produced on schedule.

The hoistway is not the only problem. One of the worst feeling on earth is when you are turning a wrench in freezing temps and it slips. Ouch! A knuckle buster is bad enough in sunny weather but in the cold? My hands ache just thinking about it. I can have empathy for the elevator installer in cold weather, but that empathy fades a bit when you realize contractually major companies won’t install in cold weather. What?

That’s right, often in the “Job Conditions” section of the contract you signed, you will find language that restricts elevator installation to a comfortable minimum of 55°F (13°C). That’s right, they don’t work in the cold leading many to believe that elevator crews watch the thermometer more than the time clock. If temps drop below the magic number, all you will hear is tires squealing in the parking lot and all you will see is a cloud of dust.

But there is a good reason and they are not being big babies about cold hands. The traditional elevator installation is the problem. For an elevator installation the old-fashioned way the elevator must be working. They ride the elevator up and down while they are cobbling all the pieces together. Because the minimum temp for elevator operation is 55° that is the line between being on the clock or not. If it is below that temp, it can void the warranty.

That doesn’t seem like too big a deal right? Until you look into average temps according to the National Climate Report from NOAA. In Milwaukee, Wisconsin it is only above the 55°F mark five months out of the year. The average annual temp is 47.7° in Wisconsin. Also, surprisingly the average temp in the continental US is a chilly 54.4°. The problem is bigger than you think. This could mean delays as the building must in some cases be largely finished before the elevator crew shows up at all. Good luck getting a job done on time.

A modular elevator is completely installed in a hoistway and in a factory! It can be cold or hot, wet or dry outside and it simply does not matter. Your elevator will be completely installed in the factory. When it arrives at the jobsite, it is not installed so to say, but set in place. The setting process takes about 4 hours at most.

Once power is provided all that is left is to turn the elevator on and set it up. A process that takes a couple days. The reason for the short timeline is that all the components are inside and ready to go. It does not matter if it is a freight elevator or a simple elevator with a small capacity. They are all equally as easy to set and start up in no time.

So why use any other method than the MEM modular elevator system? We wonder that too. If you are tired of the excuses and delays it is time to contact us for questions and pricing. We will even schedule a live virtual tour of our manufacturing facility at your convenience. Just click the link below.

Glass Elevator Easy for Experts. Its not that hard…if you know what you are doing. That bit of wisdom has been lost on many, but I am reminded of it every time I see a true expert at work. You can find them all over the place if you keep your eyes pealed. They come in nearly every line of work. For instance, I watched a tree trimmer reduce a maple tree 50″ at chest height to a stump in a matter of minutes. Unbelievable. I have seen crane operators with less than an inch to spare drop elevators into place as gently as a feather touching the ground. Astounding. They are experts. I, just a mere slack-jawed observer agog.

The key is to find the experts. And in the world of elevators that can be difficult. The reason for the difficulty is not some grand conspiracy. It is that an elevator is complex and that complexity is broken down into several job types with traditional elevator construction. So, you have the pit being poured by experts in concrete. Others build the hoistway. Finally, the elevator is being carried into the hoistway one piece at a time and then cobbled together (sounds crazy I know).

Modular elevators on the other hand consolidate the various aspects of the elevator build into one easy process for you. And at MEM with our system you have a personal project manager to assist in every step. For instance, we don’t pour concrete, but we provide an easy to use template and make sure of the dimensions. We build the hoistway and install all of the components in our factory. You get updates on progress.

It is extremely rare for crossover like this in the elevator industry. And, that crossover can only come with experience. With that even a glass elevator is easy with experts from MEM.

As an example the MEM system was use to finish a stunning, cutting edge design of seven repurposed cargo containers adjacent to a championship soccer stadium at the Great Park in Irvine, California. The architectural drawings included at glass elevator. Modular Elevator Manufacturing was called in to handle the details, put the elevator in place ready to receive the glass in less than four hours and have it started up and running completely finished inside and out. We proved that a glass elevator is easy for experts.

So, if you are wanting a beautiful glass elevator to enhance any project, but not sure where to start, start with MEM. The MEM system allows for ultimate creativity that will actually keep the elevator off the critical path saving you precious time. Remember, we are the only high-quality commercial elevator that sets in four hours or less ready to receive the glass and starts up in a week. Our knowledge about glass elevators is beyond compare as we have placed more modular glass elevators than anyone else in the nation. We are elevator experts.

So, make your next glass elevator easy! First, to get the process started just click the Fast Track button below. By doing so we can get you thumbnail numbers in about a day. Second, if you are a little interested, but still not sure about our product, you can schedule a Live Virtual Tour of or facility. We will pull back the curtain and show you how we can accomplish what some people call amazing.

During the tour we will answer any and all of your questions.

Above all, you will be able to see first hand how we produce the MEM system. Just click the Live Virtual Tour button below.

6 Reasons Modular Quality Matters – We have all been frustrated by low quality. Items purchased in good faith sometimes seem to break before they come out of the box. Or once out of the box, they look or perform nothing like what was pictured or promised when we bought the item. Instead of being happy with the purchase, words like cheap and flimsy cross our lips, meaning that we have been had. The more expensive the item, the more remorse follows.

However, in the modular industry quality is high because we take an antiquated process where onsite construction is the norm and move it to a production facility. What was then built by various people, in various trades, in various conditions becomes an orchestrated symphony of production. Historically poor quality and high cost is moved to a factory where exact processes and standards can be measured and accomplished. The modular process takes various acts of individual quality to a habit of success. For instance, our factory produced hoistways are always plumb and level. That is simply due to our factory processes that cannot be accomplished on the jobsite and it shows.

“Quality is not an act, it is a habit.”

Aristotle

As Aristotle said, “Quality is not an act, it is a habit.” And those habits are formalized into higher quality with modular manufacturing. In modular building you will never hear “close enough” or “I guess we will have to make it fit.” It is right every time, because the habits that produce quality are built in.

Unfortunately, there are outliers in some manufacturing facilities. Quality becomes just a slogan. If modular quality matters why do some not improve quality? Procedures are skipped, shoddy workmanship is allowed, new practices are slow to be adopted or worse continued tinkering and “problem solving” doesn’t allow for systems to work. In other words, if you have a team of problem solvers constantly changing the system in an unorganized fashion, the quality will undoubtedly suffer.

At Modular Elevator Manufacturing we make sure changes to procedures are checked and double checked before becoming standard operating procedures because modular quality matters. One person cannot just change something at a whim, even if it is generally a good idea. The procedure must likewise be changed with the whole team being aware of any alterations. That is where habits of quality are formed for the whole organization.

We agree with the Phil Crosby philosophy of quality and as a literal rocket scientist he knew a thing or two about it. He said, “Quality is the result of a carefully constructed cultural environment. It has to be the fabric of the organization, not part of the fabric.” Quality is not posters, or slogans or bright ideas that get used once and then forgotten.

For us quality is a top-down effort and philosophy emanating from senior leadership and permeating the organization at every level. Quality is crucial and should matter that much at every business. It does at Modular Elevator Manufacturing where we take quality seriously.

With that said here are the 6 reasons quality matters for us at MEM. There are probably more but these came to mind:

The entire premise of modular construction is that by instilling factory processes into the construction trade, the industry can produce a higher level of quality, faster and often at a reduced cost. That is what we do at MEM day in and day out. However, when slipshod practices and lack of experience infiltrate the market, quality declines. Then the premise of factory production being better comes under attack.

Whether due to ignorance, no experience or a desire to make a fast buck, when quality is ignored the reputation of the industry gets sullied. The result is a better process that produces a better product (safer, greener and faster) becomes more difficult for the consumer to accept. Who knows how many dollars, how much time and how much energy has been wasted. How many injuries could have been avoided? All due to a very small number of businesses that do not see quality as important.

That is why at MEM we do not think “close enough” is good enough. We know that low-quality has a cost to the industry, the customer and to safety. We strive for quality in all we do. Whether you need a multi-family unit elevator or one for a medical facility, an elevator for a retrofit project or new construction we provide a quality solution.

If you have tried modular elevators before and found that the quality was not as promised, don’t give up. Instead give MEM a try. We live by the above list of 6 reasons modular quality matters. You will not be sold a bill of goods for a fast buck, but instead you will find a partner providing quality you can count on.

If you have a project in mind just click the button below, we can get you budget numbers in less than a day. Of course you can also call us anytime, and have a real conversation with an expert in the elevator industry. We are looking forward to talking to you. You can also click the link for a tour of our facility. Also, we are proud of what we do and how we do it. So, if you are curious schedule your live virtual tour today.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.