ChatGPT and Modular Elevators – For over ten years I have been thinking about, talking about and chatting about modular elevators. See, I am in for the long-haul and if modular elevators are going to revolutionize the construction industry, it is going to take some time and effort. It is not going to be a simple ad buy or singular social media post that wins the day but a consistent stream of information. More than that, it will take a conversation with back and forth. The modular elevator industry needs to inform and answer any and all questions.

But, has my patience paid off? Is there more market acceptance for the MEM Elevator System than there was a decade ago?

That is where ChatGPT comes in. There is probably no better way to find out if you have broken out of a box than if a bot gives information about you when asked. That is especially true if the answer is accurate and informative. So, just out of curiosity I opened ChatGPT and typed in a simple inquiry, “Tell me about Modular Elevators.” From that question the bot responded:

Russ Ward

Tell me about modular elevators.

ChatGPT

Modular elevators, also known as prefabricated elevators or plug-and-play elevators, are a modern innovation in elevator technology. Unlike traditional elevators, which are typically built on-site in a construction project, modular elevators are constructed off-site in a factory setting and then transported to the installation site.

Here are some key features and benefits of modular elevators:

- Off-site construction: Modular elevators are built in a controlled factory environment, allowing for higher quality control and faster production times compared to traditional on-site construction methods.

- Customization: Despite being prefabricated, modular elevators can be customized to meet the specific needs and requirements of the installation site. They come in various sizes, configurations, and designs to fit different buildings and applications.

- Ease of installation: Since modular elevators are pre-built and pre-tested in the factory, installation time on-site is significantly reduced. This can result in cost savings and shorter construction schedules.

- Minimal disruption: Installation of a modular elevator typically causes less disruption to the surrounding environment compared to traditional elevator installations, as much of the construction work is completed off-site.

- Energy efficiency: Many modular elevators incorporate energy-efficient features such as LED lighting, regenerative drive systems, and standby modes, helping to reduce energy consumption and operating costs over time.

- Safety and reliability: Modular elevators undergo rigorous testing and quality assurance procedures in the factory to ensure compliance with safety standards and reliability in operation.

- Scalability: Modular elevators can be easily expanded or relocated if the needs of the building change over time. Additional modules can be added to increase capacity or adapt to new construction requirements.

Overall, modular elevators offer a convenient, efficient, and customizable solution for vertical transportation in various types of buildings, including residential, commercial, and industrial properties.

The thing that stands out to me is that the information is largely accurate. Sure, I can quibble with a word or two, but overall well done. Maybe I am being replaced?

I’m not sure you would get the same result 10 years ago if this kind of AI technology had existed back then. There was no place to type in a query and get an answer. Instead you had to sort through websites and compile information. That was a daunting task despite modular elevators being around for a couple of decades. The information was scant as there was never a concerted effort to tell their story in any substantial way. The result was only a handful of modular elevators were being sold annually nationwide and as a matter of fact, the company that invented the product and had the first factory went out of business.

Since that time sales nationwide for modular elevators have been multiplied by a factor of ten or more and now they truly are a high-quality alternative, not just a novelty.

But the question is, does a positive response from ChatGPT mean that a modular elevator is the best choice for your project? For low and mid-rise applications we think that it does. But, for you we realize that is a tough question to answer. However, with more and more market acceptance it is probably time to explore the possibilities for all the benefits that even ChatGPT recognizes.

And we try to make that easy for you. We offer a couple ways for you to get more information for your project. The first, is to look at our website and see the photos, videos, and our open and transparent process. We encourage you to explore and ask questions.

The second is to ask for a Fast Track quote. It is an easy and quick way to find out if we are a good fit. Just click the button below and fill out as much information you have. We will get back to you within 24 hours to get any details you might have missed and let you know the approximate cost and production timeline.

Lastly, you can request a live virtual tour of our factory or if you are in California, you can make an appointment and stop by. It really is that easy to join the elevator revolution!

We Understand Elevators for You – Elevators are a niche within a niche. Or a subsector of construction that no one really understands and maybe they shouldn’t. Think about it, in the US there are around 10,000 new commercial elevators installed each year.

Yet the construction industry as a whole is huge in comparison. It is more than 4% of the national GDP, and there was $1.823 trillion dollars in total construction in 2023. Lastly there are roughly 8 million employees in the construction industry. Yet only about 108,000 are in the elevator industry. That’s less than 1.5%! Elevator folks are a small exclusive club and they know it.

The upshot is that a vast majority of construction employees, architects and building owners know precious little about elevators because they don’t deal with them very often. So, honestly there is little reason for them to understand them. Most construction professionals rarely deal with elevators as they are, in context of the entire construction industry, rarely installed.

So when you have a project that must have or probably should have an elevator what are you to do?

Over the past decade or so I have come to a profound conclusion. The general construction industry, from architects to the people that swing hammers for a living, hate the elevator industry. This is due to a lack of trust and a bit of arrogance in the elevator industry. And hate is not too strong a word. We did a construction industry-wide poll and it revealed exactly that. There has a been a break in trust. This break in trust is especially pronounced in dealing with the big elevator companies. They tend to be in the habit of hiding vital information and realities of the trade from their customers.

“… a new way needs to be fashioned to revive the elevator industry and meet your needs.”

This lack of transparency has repercussions. Although you can download drawings online and talk to a salesperson (when you can get a hold of them) there seems to be little desire on the part of big elevator companies to get into the vital details of your project.

They want you to throw up a hoistway and then wait for them to complete the work when they want to. This process was fine for the 1900’s, but it’s infuriating today. A revolution was more than needed in the vertical transportation industry and alternatives were developed. These alternatives maybe a better fit for your project, but how do we mend fences and overcome the trust issue? To take advantage of possible alternatives like modular elevators, a new way needs to be fashioned to revive the elevator industry and meet the needs of the customer.

Trust must be rebuilt.

To build back trust we felt a completely different approach was needed that broke with the old pattern of the elevator industry. We have determined that open, clear, responsive, and honest information about your specific project is best. Through this approach we will rebuild trust and develop relationships that will better improve the relationships that seem to have been lost.

It begins with the premise that we understand elevators. Rest assured we do. We have been in the modular elevator business for over two decades with decades more experience prior to that in vertical transportation. But more importantly, we understand elevators for you. We know you do not have the time nor inclination to know all you need to know about elevators. We do, and our approach of full transparency throughout the entire process will let you see the difference. It will also build back the trust in the elevator industry. That trust has been lost over the years by dominance by an old out of dated philosophy and processes. But we at Modular Elevator Manufacturing are claiming it back through communication.

It is our goal as a company to revolutionize the elevator business. But this can only be accomplished with your help. You may leap to the conclusion this means you have to buy our product… we would love that. But that is not our goal. Our goal is to have open and transparent conversations about your project. So we want you to bring the hard questions. Ask us about how the unit fits in your plans, the engineering or even whether you need an elevator at all.

Those discussions will lead to a new perspective on the mysteries of the elevator industry and demystify it so you can make better decisions for your your specific project or projects.

That reformation of the elevator industry may lead to increased sales… or it may not. But we feel with more trust in the elevator industry it will improve our odds. So, if you have a project coming up and a low to mid-rise elevator is in the plans, but you need a discussion please contact us. Whether you think a modular elevator is the solution of not, we will discuss your project to help you. A great place to start and for simple numbers to compare costs, click on the button below for a FAST TRACK QUOTE. That will being the dialog.

Also, part of our effort to be transparent includes a live virtual tour of our manufacturing facility. Click that button to sign up.

Schools and Modular Elevators – Newhart Middle School/Mission Viejo, CA. Innovation can be hard to accept. However, when it comes to education, there is a long history of embracing a revolutionary method when it comes to elevators.

As an example, in Mission Viejo they embraced innovation. First, they created a brand new STEM learning environment. It will serve the children of Mission Viejo for years to come. But second, they embraced innovation in choosing the MEM Elevator System for their vertical transportation needs. But, this is not unusual as the education sector has always been willing and ready to embrace new and better technology.

Newhart Middle School is not the first school to embrace a modular elevator by a longshot. We know this because schools have been a part of the Modular Elevator Manufacturing portfolio from the beginning. Historically, the modular elevator was largely designed to be a fast, easy solution to provide accessibility for schools. The need was huge and a fast solution was needed that met their timelines. The education vertical quickly realized that the new innovation of modular elevators was the best solution and as a result a partnership was formed. For over 20 years that partnership has grown and is still going strong today.

At one time and for nearly ten years our number one selling market segment was education at all levels. These projects include elevators for dorms, schools, parking facilities, stadiums, and press box accessibility. It remains an important part of what we do as we are providing more elevators for education than ever before, but other verticals have now picked up on the innovation we provide and have caught up.

Schools remain a large part of our business model because the needs of schools are the same when it comes to the elevators they choose. The benefits of our modular elevators meets those needs so well we are the natural and best choice.

With all those benefits it is not hard to see how other verticals have caught up with the education segment of our business.

Our success in other vertical markets comes from taking the lessons we learned in dealing with various school districts and applying them to every market sector. The results is our experience and willingness to improve has led to a superior product. And as it turns out every type of business, government entity, or building owner wants the same thing when it comes to choosing the elevator for their project.

They want an easy, yet reliable and high-quality solution for their projects. We can provide that whether it is new construction or a retrofit application; in an industrial setting, commercial property, hospitality or in a school.

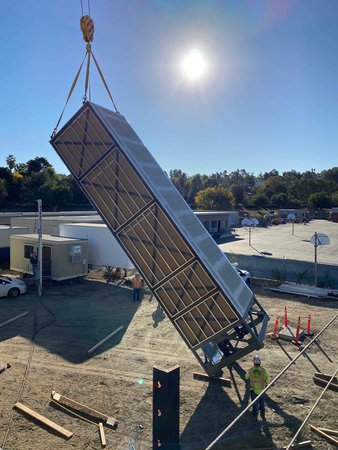

We have a solution that meets and exceeds your needs. That is what the people in Mission Viejo understood. We manufactured as elevator for them. It was delivered when they needed it. Set in place in a couple hours and started up in less than a week when permanent power was supplied. Below are pictures of the process.

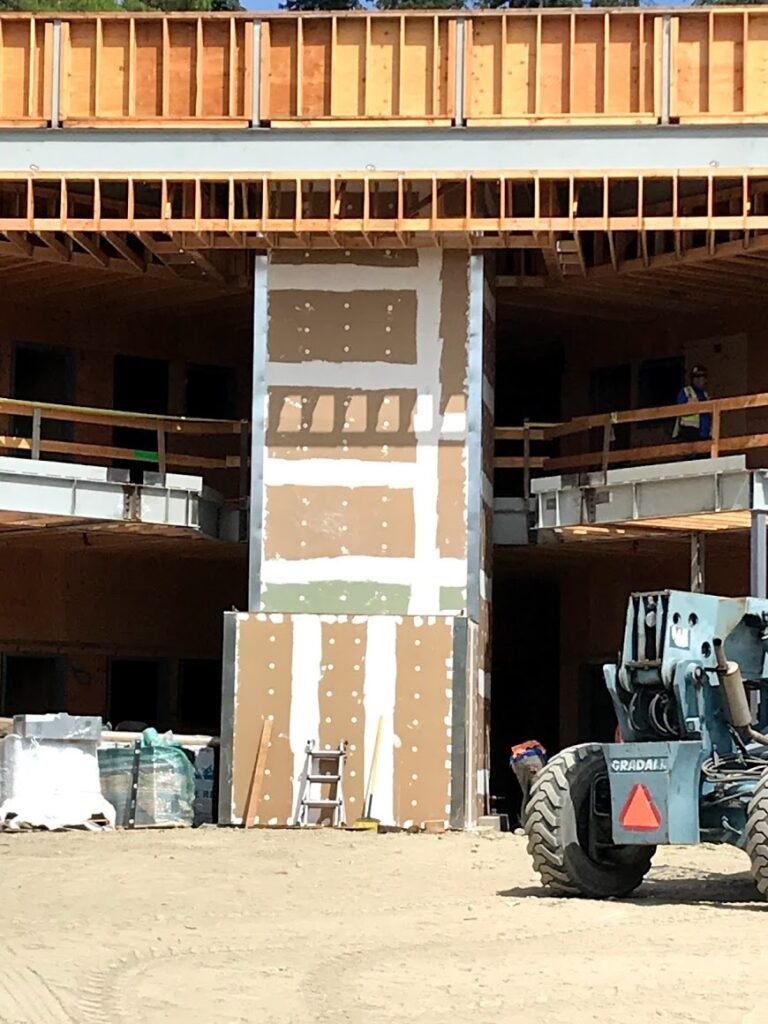

What you are seeing is a fully installed elevator being placed through a hole that was left in the build. It was set in just a couple hours and was started up in a couple of days. Revolutionary!

As you can see, the project looks great. It went in faster and easier for the school with no disruption to classes. Also, it embraced their movement towards more innovation in all they do.

If you would like to see about this project or others like it, we are opening up our factory to live, virtual tours at your convenience. All you have to do is click the button and fill out a simple form. We will then schedule the tour at your convenience. During the tour we will answer any and all questions. You can also schedule an in person visit as well.

Lastly, if you have a project in mind and want to speak directly to one of our representatives fill out the Fast Track form. We can provide you a thumbnail number in hours.

For more great photos of the project, visit our good friends at Miller Construction. Their team did a great job!

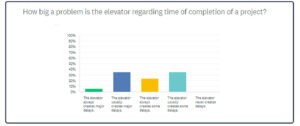

Elevator Poll Results In / Oct, 2023 – When it comes to polls the type you hear about most are of the political variety. I hate to say it, but those polls usually have a hidden purpose. They are not very straight forward and often try to lead to specific predetermined conclusions. Prognostication or propaganda? We approached our first of its kind elevator poll in a much different fashion. We actually wanted to know the truth about what construction professionals really had to say about elevators.

As a result we sent our simple five question poll to nearly 20,000 construction professionals from architects and engineers to project managers and elevator companies. We then took 12 months to gather and analyze results. Our purpose was to gauge and discover impressions, problems, shortcomings and possible solutions.

We also held multiple open forums and are now ready to share final results.

Our desire is to improve an industry that has not substantially changed in how it installs elevators or deals with the construction industry for over 150 years. To make improvements we wanted to start with actual information from the people that deal with elevators and have to live with the challenges they present.

After all, our goal is to lead an elevator revolution. You can’t lead anything unless you know where you are going. And knowing where you have been is also a big help.

As mentioned before to augment the polling data we also held a series of open forums regarding the elevator poll and industry concerns. The opportunity for input was vital because for a revolution to take off it must start with a well founded idea. But as the idea grows, connections are created and communication with like-minded individuals and companies come together. Then you can have true innovation and change.

The open forums discussed the results of the elevator poll, confirmed our suspicions and we connected through communication with folks that want the same thing; a responsive elevator industry that provides solutions not obstacles.

Everyone involved (including elevator professionals) want to change the practices and products for the better. So what are the findings?

You can access each individual graphics below by clicking on them. Using the polls and with the help of our open forums we came to some important conclusions for the elevator industry and how it is viewed by the construction industry as a whole. But don’t take our word for it. We encourage you to look at the graphics and add your comments below as to what your impressions are. Forward this to others for their input. As time goes by we can enhance our perspective. This is because we are searching for truth and not trying to promote a specific perspective. We feel communicating and continued analysis will help both industries (construction and elevator) improve.

The responses and discussion groups revealed the following:

The overall customer experience is negative regarding the elevator industry. Over 88% feel the experience was horrible to needs improvement. Over 40% felt it was horrible to barely tolerable. No sugar coating it, it is not a good result. However, keep in mind this attitude shifts dramatically depending on occupation or role. 90% of design professionals believe their experience to be generally good. Easy to use websites for plans are a big help. Turns out however, websites can’t install an elevator. This also means that the elevator industry focuses effort on the sale of elevator units, not difficulties of those downline from the decision.

A possible reason for the negative experience is the elevator interrupts job completion. 65% in our poll say the elevator always creates delays. At the end of any build, the pressure is on to finish up. Tensions run high as time is running out. One person we talked with about the frustration said, the elevator company indicated they would have to push out more than 6-months passed the expected occupancy date. Understandably he was apoplectic, but stuck and he knew it. His impression of the elevator industry is forever harmed.

The traditional elevator industry has no solution for the pace of the install. They will be done when they are done and the timelines for the elevator crew are often times at odds with the construction manager’s expectations. Bad communication and unresponsiveness may be the heart of the negative reviews.

The most important consideration regarding the purchase is on time start up and use. But there is no control over that with current industry standards. The conventional elevator is an immovable object stuck on the critical path. That creates a feeling of loss of control or helplessness.

Cost, Type of Conveyance and Structure are also concerns that sometimes present few options for improvement. Too often based on poor specs, builders are over sold regarding conveyance type for the building with hidden costs. Also, cost of the elevator does not encompass all the ancillary aspects of the build, so at the end of the project the actual investment in the elevator is unknown.

How much money per stop is wasted due to call backs of drywallers, flooring and painters? One construction professional has indicated the traditional elevator cost him $30,000 to $40,000 more per stop due to call backs of other trades. He found another alternative.

Good News! There is flexibility as no one polled automatically keeps the same elevator company due to past experience. This means change is possible. However, pushing the choice of elevator to the bidding process leads to specs that stifle innovation. As we have learned and discussed in our forums, elevator companies largely ignore the specs anyway. They supply bid packages with tons of caveats and wherefores, not even addressing specs. So why push the decision out to or past the bid process where you are now under more of their control?

By the time you are passed the bid phase, it is often too late to consider other alternatives without additional costs. All hope of innovation is gone. Ultimately, construction professionals are often locked into just a couple bad choices. It also sets in stone an unfavorable timeline for project completion.

Difficulties – Start up is the elephant in the room. It is a huge issue, but out often out of anyone’s control, including the elevator installer, especially regarding inspection and final approval. Cost overruns are a huge and constant issue. Also, the lack of communication costs time and money on the project. One example provided was the inspection of the elevator was pushed by the general contractor to be expedited. This led to the elevator being fully ready… but life/safety aspects of the building were still not complete. That meant a failed inspection and then change orders to return for a second scheduled inspection. Open communication would have resolved that issue before it became one.

This poll and open forums lead to a great starting point for the construction industry to begin to change how it views elevators and all the pitfalls. It also gives Modular Elevator Manufacturing and others in the elevator industry the perfect opportunity to change the industry from the inside out. In the next blog post, we will get into the specifics of how the elevator industry can change to improve its image, product and installation.

We will continue to discuss how a revolutionary way of dealing with real issues can improve your projects, reduce headaches and can lead to a better way of building. Elevators will never be problem free, but they can be improved and that is our hope as we lead an Elevator Revolution.

In the mean time if you want to know more about the MEM Elevator System please let us know by clicking a link below. You can take a virtual tour of our factory where we openly discuss our process and the elevator industry. You can also request a Fast Track Quote if you have a project in mind and are curious about the solutions we offer. One more reminder – please comment below. Your input is important.

Quality is crucial when it comes to anything we buy. That is especially true when we are talking about a commercial quality elevator. The stakes are high and a shaky elevator ride can give a person a lasting negative impression. But more than that a commercial quality elevator carries passengers. So there is a need for quality for the sake of the safety of the elevator riding public. Quality is important. Yet it can seem illusive as with most projects the elevator is the biggest moving object in the build and extremely complex.

Additionally, apart from safety and overall building aesthetics (feel of the ride) there are many others reasons why quality is so crucial too. A lack of hitting high standards also cost time and money on projects. We have all experienced a time when we made a purchase only to return the item for a replacement and then had to return it again. Frustration, waste, anger, agitation and disgust filled our minds as we get in the car for the third time. With quality there is assurance, peace, pride and pleasure.

So how do we achieve our high standards and why do we say “commercial quality elevator” so often?

First we tend to say it a lot because of factors beyond our control. Perception can be misleading, but in the minds of many a reality. With modular there is sometimes the perception that with the ease modular provides there must be compromises. The product in many ways seems to good to be true so mentally there is a leap to possible issues that don’t exist. We have been working diligently for decades to dispel that notion. In every project we produce we care deeply about quality and it shows. So in reality it is more of messaging to correct a perception may have had some grounding in fact, but is now decades past its shelf life. We are quality at MEM.

We also sometimes have pushback from a threatened industry. The monolithic elevator industry sees the writing on the wall, but due to their business model, they cannot extricate themselves from the traditional elevator build and installation. They have literally been doing elevators the same way since the mid-1800’s. No kidding. Elevator installation has not changed since the Civil War… our Civil War… in the US… over 160 years ago! In 1859 the Cooper Union Foundation Building had an elevator shaft built in (even though passenger elevators were not available). Then, once completed the elevator was brought into the shaft on piece at a time just like today. That model has not changed since. What other product on Earth has seen less innovation in its process since the 1860’s? Innovation threatens so they attack.

In a nutshell, the above are the reasons we stress our quality so much.

More importantly, how do we achieve quality? We can say we have quality and that quality is worth having, but all that talk is completely nullified if we can’t produce it. We do and I came up with five ways we assure quality with every project going out the door:

This refers mostly to the hoistway, elevator car and sling and other items we manufacture in house. The factory process uses templates, quality materials and well thought-out and practiced procedures. For instance our cab is tough Galvanneal steel easily produced to exact sizes by use of templates and guides. We would never use flimsy particle board covered in glued on laminate. That kind of cheap product is apt to warp, expand and flake.

This term encompasses the pride of the team members at MEM and their experience. It begins with the sales representatives. They are the most informed and knowledgeable people regarding modular elevators and elevators in general you can find. This is crucial as they guide the process from beginning to end. They set the pace and know each project completely and intimately. We also meet every jurisdictional requirement with licensed welders, electricians with years of experience and employees that have pride in their work. Lastly, we thoroughly inspect every elevator we manufacture with a 10 Point Inspection – Check List. Using that list a certified elevator technician performs the inspection. In this way you can be sure that when we ship an elevator, it is the quality we promise. We also provide consistent inspections through out the build.

Dirty little secret…they are all the same. It really does not matter the name plate on the control panel in the car. Every elevator contains roughly the same components. All the parts have to meet the same high standards regardless of the company providing them. High-quality standards are demanded and required by law, by jurisdictional code and by regulation. We abide by all to produce quality everytime.

Our factory process produces consistent quality. But that does not mean we are stuck in old ways or not flexible in design. We think though what we do, provide for flexibility and constantly assess how we can improve. We test and update our process as needed. Additional benefits including being inside a factory. Cold and heat do not interrupt our manufacturing, nor do they act as an impediment to consistency. Whether we like it or not if it is snowing outside at 20 degree, traditional construction suffers. This is seen every time a traditional built hoistway it not plumb or level. Our building practices are perfect every time and on time every time.

Two quick points. Our design is based on more experience than any other modular elevator company. Also, the engineering is improved consistently over time. We have made design improvements that others have not. Also, not only do MEM elevators meet the engineering standards of difficult Seismic areas, they are also used in high wind or hurricane areas. The MEM Elevator System is also designed for more efficiency in installation and setting the elevator. Our experience in the industry makes us the leader in design and engineering.

When we say our team has a fully-installed commercial quality is set in four hours we mean it. The same goes with start up. When power is available we can have your elevators running in a week. This is due to our superior quality. Our team consists of elevator people through and through. Passing inspection easily is the rule because of the design, engineering, production process and quality.

It is one thing to talk about quality and quite another to see it. So we invite you to see it firsthand. You can click below to schedule a LIVE VIRTUAL TOUR. We will pull back the curtain and let you see what we are doing, how we do it and why it is the best option for all low and mid-rise projects. The difference in quality will be clear. Of course during the tour you can ask any questions you want. We are open with our process and proud to show it off.

If you have a project in mind already click the button below for a FAST TRACK QUOTE. We will contact you for additional particulars, but will provide you with a budget number with in 24 hours. There of course is no hard sell or obligation. We just want to be able to answer your questions, find out your challenges and help be a solution. That is how we are a part of the elevator revolution.

Best Argument for a Modular Elevator – I am very lonely in my job as a marketing professional in the world of modular elevators, because at last count, I am it. If there is a new one out there, welcome to the revolution. But, for now its just me.

The reason I bring that up is single handedly I have written hundreds of articles supporting the modular elevator industry and I am on the constant look for two things. First, a new perspective or way to spark interest, hone my argument or new way to discuss the modular elevator industry. Second, help. This comes in the form of any supporting information, blogs, studies, whitepapers or reports. I scour the internet and other resources constantly and as a result, with the help of one of our team members, ran across a great new article. It was surprising help from an unlikely source.

A LinkedIn contributor that goes by Dr. Michael Simmons, DBA wrote a very concise and clear, step-by-step description of what a typical hydraulic elevator installation looks like. This is not a modular installation mind you, but a traditional run-of the-mill elevator install. The article is entitled How Do They Do It? Hydraulic Elevator Edition and I encourage you to take a look at it. It is 1000 words of exactly all the steps that have to take place to install an elevator with the traditional installation method.

So why did I find the Best Argument for a Modular Elevator in an article about a regular elevator installation? Because it proves beyond any shadow of doubt, in simple and clear terms, the lunacy of traditionally installing an elevator. The antiquated process comes with a myriad of problems and challenges that frustrates the building owner or build team. Below are just some challenges taken from the article.

These are just a few of the potential injury risks, ways the project can be delayed, inefficiencies that come with the the process and challenges regarding quality. Modular elevators are completely different.

With an MEM Elevator System the commercial quality elevator is manufactured in a factory with quality controls and constant inspection. First, the hoistway is built with jigs and precise templates to assure it is always plumb and level. Once the hoistway is finished and wrapped in drywall for fire protection according to code, doors and entrances are factory installed.

Meanwhile the elevator sling and cab are being built in a separate location in the factory. High quality Galvanneal steel is used for the cab walls to ensure durability and longevity. During assembly our build team can freely walk around the cab as it is being built and precise jigs are used to ensure a perfect fit in the hoistway everytime.

The wiring is complete in the factory as well.

The last step is to insert the cab into the the hoistway. Done.

The benefits are tremendous. The quality is higher, inspections can be completed throughout the process, it greener as there is less waste, and there is no interference with other trades or reliance on others to complete the elevator. When you need it, it is craned into place and that’s it. The process is so fast the elevator can be used as a construction lift saving even more time and money. You get the elevator when you need it not at the arbitrary timing of an elevator company.

If you took the time to read the article that gave me significant help and inspired my post, think about it. All of the headlines in the article contain the various steps of a traditional install. With modular elevators they can all be skipped! No headache for you as you can simple draw a line through elevator on your to do list. We take care of everything making it the easiest way to have an elevator in your building. The only step we need is adjustment and inspection once power is on. That’s it. You get to skip to the end.

This means that the elevator is off the critical path and not getting in the way of all the other trades on site. Also, crews won’t waste even a second waiting to finish around entrances. That work can be done in sequence. Lastly, this means you save time, money and countless headaches. It is the best argument ever for a modular elevator.

As you can see, the modular concept for elevators is revolutionary, but this concept is not new. We have been at it for a long time and have hundreds of elevators installed nationally. Also, we are pioneers in the elevator industry seeing a need and creating a great solution. The old elevator industry needed improving in safety, quality and fast start up and we did it. Something that would takes weeks with traditional installation now takes a few hours. Its time to join the Revolution.

Click the button below to get a Fast Track Quote or if you want to explore a bit more request a live virtual tour. We will pull back the curtain and show you how we produce the MEM Elevator System.

Disney, the world class entertainment company, prides itself on cutting edge solutions, quality, and consistency. So, it is no wonder that the House of Mouse has found a solution to elevator woes. Modular elevator and Disney are a perfect match. But they are not alone. Everyone in the construction industry is constantly trying to find a way to deal with slowness and unresponsiveness of the traditional elevator companies. Disney found a fully installed elevator can be placed on the jobsite in less than four hours.

As you can see in the video to the left, the elevator arrives on a flatbed truck with the elevator jack. The jack is then placed in the pre-drilled hole and then the fully installed elevator is lowered into place. Everything is ready to go from the doors and entrances to awnings on the exterior. All the wiring is already in place as well as the fully constructed elevator car.

This is the perfect solution for any low or mid-rise application. And the MEM Elevator System is not just relegated to modular projects or parking garages.

The Disney project was specifically for a resort that needed access to a parking garage. However, the flexibility of our modular elevators goes far beyond that limited use in both type of construction and vertical markets.

For instance our elevators have been used in affordable housing projects, educational institutions from elementary schools to major universities, medical facilities, commercial buildings, and more.

When it comes to types construction for a project, there are no limits. Do you have a stick built project? We can be your solution. Modular? We are a perfect fit. Steel frame? Absolutely. And of course concrete construction.

How can there be such flexibility? Because in most cases the MEM Elevator System is designed to be a free standing structure meet all local codes regardless of earthquake or wind concerns.

Our Elevator System is flexible enough for any design challenge. So, contact us and be a part of the elevator revolution we are leading. For more info on solutions for you, click the button below for a FAST TRACK QUOTE. If you want to explore more just sign up for a LIVE VIRTUAL TOUR of our facility. We are open and willing answer questions and have discussions on viability for your project.

Early In Means Elevator When you Need It – Can you get an elevator when you need it? Including MEM early in a project means you can. Of course the alternative is the traditional way when the elevator company tells you, you can have it? But if you are tired of letting one industry dictate your construction schedule there is an alternative. The “alternative” has a long track record of success as the solution. It is also being embraced nationally by major construction companies, architects, design build firms, building owners and elevator installers.

The solution is the modular elevator and MEM is the leader of an elevator revolution with the MEM Elevator Solution. Make no mistake, modular elevators are the future. There is no doubting that. It is and will be a reality that very soon a modular elevator will always be the first option in any low or mid-rise application. They go in faster with fewer headaches and difficulties overall. The price is competitive to better and the components are largely the very same you will find in any other elevator. There is only one way that this growing trend will be up-ended and that is if modular elevator companies themselves don’t live up to the promises they make and the quality they market.

That seems to be what is happening at least to some extent currently. For instance, there is an often repeated 8 week delivery of an elevator. If a company makes that claim, be aware that there are dozens of caveats and requirements that cloud the numbers. We reject that marketing ploy and want to be included early on projects so we can deliver when you need the unit not at some inconsequential and artificial timeline.

So with the above all true, how can they make an unrealistic promise? It is, “Sell the elevator and pray for rain.” approach. They know in all likelihood that the early stages of the project will not go off without a hitch and the financing, ground breaking, permitting, site prep, foundation and elevator pit pour will be delayed. This gives them time to get the elevator done before shipping. At least that is their hope and why their fingers are crossed.

Ultimately, the promise of the eight weeks was never realistic to begin with and never is intended to be adhered to by the elevator company. Heaven help you if you are efficient run a tight timeline and the weather cooperates. Odds are if you believed the canard of eight weeks…the elevator will now leave you frustrated and sour on modular elevators. We see people hesitant to use modular for just that reason. Once a promise, even one as outlandish as an eight week elevator is broken, trust is hard to earn back.

How is the MEM Elevator System different? We want to be early on the project so we can always deliver the elevator when you need it. There is no promise of a fictional and arbitrary timeline. We are honest from the beginning and listen to your needs. Then together we determine when it is best for the elevator to be delivered. We discuss if the elevator should be delivered first in the project, in the middle or the end. In the above photos, you can see it was determined that the elevator should go in after framing. Others go in first or last. We also discuss any special requests or specific difficulties to overcome. For instance our elevators are often used as a construction elevator to cut costs or for schools holding back the delivery date for a holiday or summer break.

The expected delivery date is then generated and the process begins. We know delivery dates fluctuate in every job, but having a general timeline for delivery is the best possible practice for the entire construction team. To keep things on track you have a personal contact that will touch base as needed to update the schedule. Everyone is always kept in the loop.

In our process while you are dealing with a million other questions about the project, permitting, figuring out subs and the rest of your project schedule we are ordering all the components, doing the paperwork, and creating the elevator schedule. With all that done and ready, the elevator is placed in our production line when it will be completed as you need it. It then arrives as promised.

This is truly revolutionary. No longer are you being told when the elevator will be finished. You have control back.

So to ask the question again, can you get an elevator when you need it. Yes you can, but MEM being early in is crucial.

If you are interested in the concept of a modular elevator and would like to find out more about the MEM Elevator System and our elevator revolution, you can have a Live in person or even Live Virtual Tour. Just click the button below. We would be glad to pull back the curtain and show you around. This will allow for you to see with your own eyes our concept come to life and answer any questions you may have.

If you have a specific project in mind just click the Fast Track Quote button below. It will get the process going and we will contact you with costs. Overall we strive to be transparent and willing to discuss your needs so we can provide a great solution. We look forward to working with you when you join the elevator revolution.

Shorten Elevator Lead Time – One the best kept secrets in the elevator industry is the timeline from a contract being signed until the elevator is delivered and then passes inspection. I am no conspiracy theorist, but it seems that no one wants to talk about the subject in the least. See for yourself. Go ahead, I encourage you to search for a source on any platform that tells how long the timeline is for a commercial elevator installation. I’ll wait…

So what are we to do if you want a general timeline for getting an elevator installed in new construction or even a retrofit application? It is kind of important to find out how long generally an elevator takes to install and get running, right? Now, I can tell you how long it takes for the MEM Elevator System, but as a rule in the elevator installing world that is a top secret. As a result, for that information we are stuck with general polling and anecdotal stories. The need for you to know that information is the lack of knowledge does not allow you to compare the facts of the install and puts you at a disadvantage when deciding on the elevator type and company.

Now up front there is not a poll completely on point. However, there are a couple that can give some guidance. There is no denying the timeline when actually applied to projects is a huge problem in light of these polls. One of the polls of construction industry professionals found that 100% of respondents said the elevator “always created major delays” to “usually creates some delays”. In this day, when people rarely agree on anything 100% is astounding. But get this, 0% or none said that the elevator never creates delays. So why do so many respondents think there are delays? Because the timeline for completion is not accurate from the outset or one has not been established or taken seriously by the elevator company.

This result was replicated in another question in the same poll that asked, “What are the biggest difficulties regarding the elevator?” A full 82% indicated that delays in start up were the biggest problem. Am I crazy or does the elevator industry have an issue? Maybe both?

The results could be waved away if it weren’t for so many stories we are hearing from elevator installers, project managers, and building owners. Often they contact us or request a Fast Track Number stating the reason they called was because the lead times from the major companies were so long. They felt they were given every excuse in the book but no solution to delays. They mentioned production delays to manpower shortages as to why the expected delivery date and installation was over a year out. And the timeline for some has even been stated to be in excess of two years.

In an industry that is so slow to respond (as seen in this short video) what are customers supposed to do? Where can the buyers of commercial elevators find the answers they need? Where can they get a reasonable timeline? First, a quick examination of why the delays.

Having a hoistway built first and then sit empty until there is permanent power is lunacy. But this is the general way elevators are installed. Months tick by while nothing is done in a fully finished hoistway. Then once permanent power is provided the elevator installation company arrives. They take over and get in the way of every other trade filling a predetermined area with parts, pieces, tools, and components.

The reason for the need of power is that the elevator has to be operational to install the rails and clips as they use the elevator as a work platform. If the area is not climate controlled and the weather gets too cold or hot, they simply stop work. Try getting an elevator installed in the northern US or Canada without delays if you don’t believe me. An old saying is that in some climates the elevator installer watches the thermometer closer than the timeclock.

Meanwhile as every elevator component has to be carried into the enclosed hoistway and screwed, bolted or cobbled together work is slow, laborious and often unsafe. There is lots of heavy lifting and risk of dropping objects inside the shaft.

Only after all of the work is completed regarding elevator doors and entrances can other trades such as rock and tape crews, painters, flooring installers and exterior finish workers can return to finish the job. In most cases it means more delays usually unaccounted for.

Simply put it is a mess; a slow, plodding, inefficient mess. Beyond that, the completion time of the whole project hangs in the balance because the elevator is smackdab in the middle of the critical path. The elevator shouts, “None shall pass.” at the top of its lungs and the project grinds to a halt. All stops when one hoistway heaves with cold weather, one part is on back order, with one injury in a dark dangerous hoistway, one misplaced tool, one blown console, one little problem and the whole project grinds to an unforgiving halt.

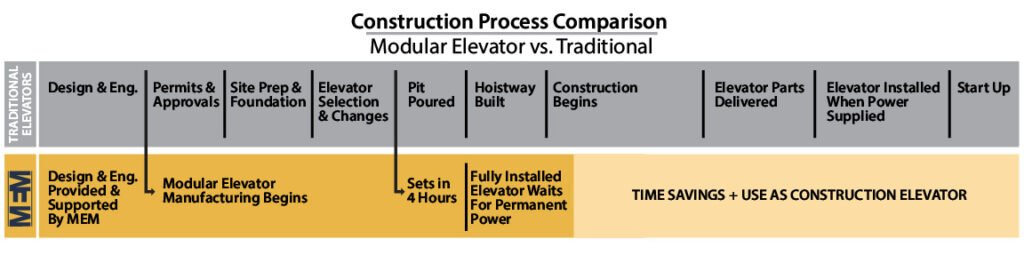

A better or revolutionary process changes the entire game. We provide an elevator when you need it not tied to the old fashioned practices. In the chart below you can see how we are different.

The traditional elevator process is linear and mired in design and engineering of the hoistway, to gathering up all the parts and components. Our system is not. The MEM Elevator System is delivered hoistway and all, fully installed. It is placed in a couple hours and can be started up in as little as a week. We start with the day you need it and then count backwards in days to place it our production schedule to be be delivered on time every time.

It is so fast in delivery and set in just a couple hours, that it is often used in lieu of a construction elevator on some projects saving even more time and costs. When modular units are built in factories, the time is simply shortened. But what is not incorporated in this chart are the ancillary savings and benefits.

More and more builders and building owners are joining the revolution. They are exploring what modular has to offer and how the modular timeline can be a huge benefit.

Our MEM Elevator System is beneficial for the whole project and the results are stunning especially when taken of advantage of in full. Can you imagine how your project would change if you could determine when your fully installed elevator arrives? Then started up in less than a week? Or realizing it goes in so fast it often doubles as the construction elevator on the job? That is a game changer, especially in current times where every penny counts.

So now is the time to act if you have any questions about modular elevator or the MEM Elevator System. If you are the least bit curious about Modular Elevator Manufacturing just click the button below. You can get a LIVE VIRTUAL TOUR of our factory. We will pull back the curtain and let you look at our process and how we are leading the modular and elevator revolution.

Do you have a project in mind? To get thumbnail numbers to consider, just click the Fast Track Quote button below. We will be in touch in less than 24 hours. At that time we will give you an idea of how your project will be improved and your investment. You will also find out what it takes to make a change for the better.

A Childlike View – Modular Elevator / Usually the posts on this blog are fact based, analytical, driven to find solutions to problems and serious. But that is not real life. I was reminded of this over the past weekend when I had the pleasure of hosting my granddaughter for a Saturday afternoon. She is just three years old and to her everything is new, a wonder, an exploration and excitement. I came to the conclusion that we all need more of that in our lives even at work. Somehow as we have matured, joy in discovery and wonder has slipped from our grasp. We replace those things with a healthy dose of skepticism, cynicism, and entrenchment. Sadly the innovation around us becomes stale, opportunities dim and adventure is cut out of the equation.

I hope that this short post wakes us from our slumber a bit and shakes us into seeing the possibilities and excitement of new opportunities. Hopefully, it will make some parallels regarding seeing the world a little less pessimistically, being open to new experiences and giving modular elevators a try. However, that is not the real purpose of the lessons learned. It is more about philosophy of life and why we need to embrace the happiness of adventure and the joy of wonder through a child’s eyes. Besides I get to post a couple photos of the cutest granddaughter in the world.

Let’s not go too overboard on the comparison. However, think about risk, thrill, wonder and trust. We can all find those things in our lives. But when was the last time you experienced it at work. Far too often we get real comfortable between the hours of 9 to 5. We reject the new for traditional, see only downside to risk, and lose wonder and trust.

Suddenly we find ourselves trapped in patterns endlessly. Yet we wonder where all the excitement went compared to when we first got started in our careers. It is often said that, if you always do what you have always done, you will get what you have always gotten. So, how’s that going for you? Especially regarding elevators.

So, if you will allow me permission to offer a bit of advice.

Life is far too short to continually do the same thing day in and day out. Muddling by is not how we are wired for a full life. We strive for comfort in repetition, yet it becomes the snare we have trouble extricating ourselves from.

So stretch your legs. Take a chance. Walk to the edge. You never know, you may find joy in the view.

Thanks for taking the time to read this over. I hope you take some of it to heart where it applies. I certainly will.

Now about elevators. Just because you see the risks of modular, don’t think that we don’t do the calculations, the cost estimates, the engineering and planning. Everything is ready and the whole package is prepared. We make placing a fully installed elevator extremely easy and enjoyable. Now it is up to you to take the chance and discover more.

I do feel compelled to at least mention modular elevators and the MEM Elevator System. It is the best solution for any low or midrise application. They are commercial quality and literally get installed in just a few hours.

If you would like more information or have a project in mind and would like general pricing just click the FAST TRACK button below. If you are interested, but want to learn more, click the button below for a LIVE VIRTUAL TOUR. We would be glad to solve your vertical transportation woes.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.