Construction Hoist

The Modular Elevator Manufacturing (MEM) Elevator System is a perfect solution for use as a Construction Hoist on projects that eliminates the need to rent a costly external hoist to meet OSHA Standards.

Basically with the MEM System you get two elevators in one. A commercial quality elevator plus a construction elevator.

An MEM Modular Elevator System is ideal for projects with up to 75 feet of elevator travel and projects with exterior site space limitations.

The MEM System is pre-engineered for seismic and wind loads and is attached to the building as it is constructed.

The Modular Elevator System is installed early in the project and the building is constructed around the elevator.

The Machine Room is fully constructed and the Modular Elevator becomes operational under temporary power.

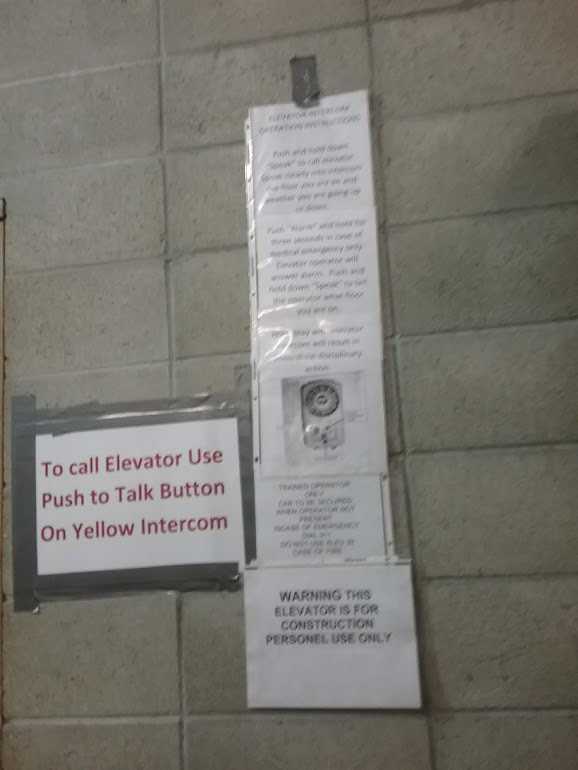

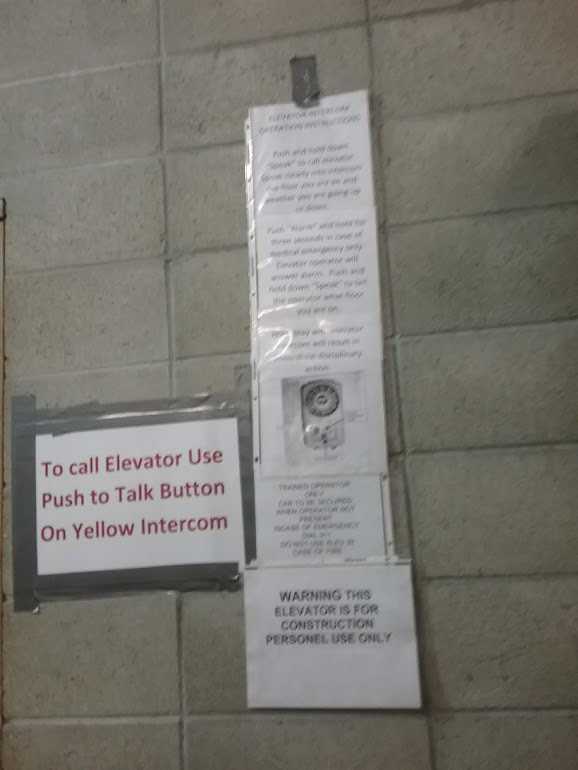

The Modular Elevator is DOSH permitted for temporary Construction Hoist usage at each pre-determined floor level as the building construction goes up.

The Modular Elevator Cab is temporarily protected and set up for Construction Hoist usage. The elevator cab is fully protected while in use.

But, rest assured that once usage as a Construction Hoist is complete, the cab is refurbished to factory standards, or with one of numerous upgraded finish options, and the elevator receives a permanent DOSH operating permit.

Due to the potential duel purpose of both a construction hoist and permanent, high-quality elevator, there is no other product on that can save costs like the MEM System. For pricing or information click the button below.

Elevators Made Simple

Simply Put – the Modular Elevator Manufacturing (MEM) Elevator System is an innovative solution that consists of a full conventional commercial elevator pre-installed in a Pre-Engineered Hoistway, fabricated off-site. It is then delivered to the job-site as a complete Hydraulic Modular Elevator solution for projects with up to 75 feet of elevator travel for both interior and exterior elevator applications.

Design and Construction

Made Simple

The MEM Modular Elevator System greatly simplifies the complete elevator design and construction process. Each elevator is built, based upon the loal and state building and elevator codes. You are assured of:

- Stamped Drawings and Calculations for JHA Approval

- No Hoistway to Design or Construct

- No Hoist Beam to Design or Construct

- Pit Ladder is included with a Modular Elevator

- Pit Light is included with a Modular Elevator

- Pit GFCI is included with a Modular Elevator

- Pit Switch is included with a Modular Elevator

- Hall Stations are Mounted on Elevator Door Frame

- Fire Rated Hoistway Walls Included

- Services only need to be brought to Machine Room on the ground floor where the Modular Elevator takes it from there into the elevator pit.

Fast Track Delivery and Installation

The Modular Elevator System eliminates the delays associated conventional elevator construction that has to wait for the building to be complete before the elevator can begin to be installed.

- A Modular Elevator Delivers approx. 20 Weeks after Approvals

- A Modular Elevator Installs in 1 Day

- Elevator Start-up in a Week after Services are Installed

- Shortens the Project Critical Path

Non-Proprietary Components

Equals Life-Cycle Savings

The MEM Modular Elevator System only utilizes non-proprietary components from the major elevator component manufacturers. This offers greater flexibility to maintain the Modular Elevator system over its life without expensive long-term service contacts.

- Non-Proprietary Components

- Major Components from the Best Manufacturers

- No Long-Term Service Contract Required