Georgia Welcomes Modular Elevators – Morrow, GA. With our partners at Georgia Lift Solutions an MEM Elevator System is now in place in a community center in the state of Georgia.

The two-stop project is the first modular elevator for Georgia Lift Solutions and demonstrates how easy installing an elevator can be.

Kyle Floyd and Dillon Graham of Georgia Lift Solutions became interested in the MEM Elevator System a year ago and saw the potential of a product that cut the project time, reduced ancillary expenses, and provided a high-quality solution. They toured the MEM factory and found that the MEM product would be a perfect match for their organization and many of those needing elevators in their service area.

For them a modular elevator is a great way to grow their business. As the units come fully installed, placement takes less than a day and start up less than a week. They recognized that a traditional elevator would suck too many resources and take too long to complete for their business model. The MEM solution was perfect.

To further explain: a traditional elevator arrives on pallets and is literally assembled, one piece at a time, in an existing elevator shaft. Unbelievable but true. That process is labor intensive, slow, difficult, and dangerous. The difference is manufacturing of the MEM product. In a factory setting a sturdy steel elevator shaft containing all the parts and components is produced.

Everything is installed including the doors, rails, wiring, hall calls, and even the elevator car. MEM National Sales Manager – David Torres explained the difference this way. “A traditional elevator is like buying a car from a dealership, but instead of a new car arriving, it comes to your driveway in crates and boxes, then a mechanic shows up when they want and assembles it right there.” He went on to say that, “No one would ever purchase something as complex in that fashion. As a modular elevator arrives fully installed modular just makes more sense.”

The set at the community center went as promised with the entire process taking less than a day. The elevator arrives on a truck and it is lifted at four points by a crane. It is then rested on cribbing and the crane connection are adjusted. Then it was lifted vertically and carefully placed on bolts in the pre-poured concrete elevator pit. Easy.

Now, once permanent power is provided the Georgia Lift Solutions team will return and start up the unit. They will make sure it levels properly at each floor and then ready it for inspection and use. Simple.

This fast and smoother modular product is revolutionizing the elevator industry and it is long overdue. See, the traditional way of elevator installation is one piece at a time in an existing elevator shaft. That has not changed since the 60s…the 1860s. The need is for revolution. And, the MEM Elevator System is leading that revolution. See the video below.

So, are you ready for a better alternative to the old-fashioned elevator industry? If so, we are ready for a conversation. For your next project it maybe time to explore the possibilities of the MEM Elevator System.

To see how our innovation in the elevator industry can be a perfect fit for your project click the button below. We can provide a Fast Track Quote or schedule a LIVE VIRTUAL TOUR of our facility. We would be happy to pull back the curtain and reveal our process. It shows how we produce the industry’s most successful modular elevator solution.

Elevator Revolution – Low-Rise Really Easy. Projects are complex with lots of moving parts. Electrical, plumbing, heat and air, structural concerns, finishes, the foundation, openings, and more needs constant attention and adjustment. The logistics of all those construction divisions suck time and resources from already busy schedules. This makes keeping everything on track, on time and moving forward more than a headache to say the least.

So, every once in a while it is a relief when there is a simple solution. A solution that takes an entire part of the project off the critical path, instead of placing it on the to do list. The MEM Elevator System does just that and makes it easy. It allows you to scratch a line through that part of the building project and not think about it again.

The MEM Elevator Solution is a simple solution because with a modular elevator there are only two steps for you once the contract is signed, the purchase made, drawings are approved, and the pit is poured. The first step is a fully installed elevator delivered to the site and craned into place. This step takes less than four hours and none of your time unless you want to watch it go in. The second step is once permanent power is supplied, the elevator is started up. This take around a week. This was exactly the process of one of our most recent projects, Los Osos High School.

Projects like Los Osos High School demonstrate our fast, high-quality solution through forward thinking and superior engineering. See, traditional elevator companies are just stuck in old thinking when it comes to elevator systems. Traditional elevators are anchored in the 60’s (the 1860’s) with no desire to upgrade their product models. As a result they have no idea as to why installations are such a pain for the owner, architect, project manager and designer. And they certainly have no idea as to how to find solutions. Traditional elevators are stuck in a time warp.

Engineering experience and knowledge in the elevator industry is crucial to make your project a success. We have both. The end user needs to know nothing about an elevator other than it goes up when you press a button, but we do. And it matters.

It matters because that is what allows the installation to go in smoothly and quickly without delays and complications. The process is then a success and it leads to a headache free jobsite. Also, because of our expertise and knowledge we are able to accommodate special requests and special circumstances. Others run from projects that need to incorporate a corner post, or difficult applications such as inside the Spruce Goose Hanger for Google. Because of our engineering, knowledge and experience we enjoy the challenge and the results.

This was true on the Los Osos High School project. Everything went according to plan and according to the timeline that was most beneficial for the project. As we all know, schools have a difficult timeline to say the least. Even when it is new construction the calendar of the school district reigns supreme. That brings lots of pressure to bear.

At Los Osos High School a fully installed elevator was delivered when promised. And it was up and running on time with no complications. Wouldn’t it be nice to know that the elevator is taken care of completely? That is possible with the MEM Elevator System. Through engineering and our knowledgeable team we can deliver.

We have a well thought out approach when it comes to durability, quality, safety, and speed. That is due to our decades of experience in the elevator industry in both service and manufacturing. We know the challenges so you benefit from our years of knowledge. Bottom line, we know what it takes to design and build one tough elevator. But beyond that, we deliver it when you need it on the jobsite as a fully installed unit. Here are some videos showing how easy it is.

So, for your next project it maybe time to explore the possibilities of the MEM Elevator System.

To see how our experience in the elevator industry can be a perfect fit for your project click the button below. We can provide a Fast Track Quote or schedule a LIVE VIRTUAL TOUR of our facility. We would be happy to pull back the curtain and reveal our process. It shows how we produce the industry’s most successful modular elevator solution.

Hope On Hyde Park/Los Angeles, CA – Mission accomplished. The Hope On Hyde project is a great example of everyone pulling together for a great outcome. Our small part for this affordable transitional housing community for the Los Angeles area is complete. As a result we thought we would look back at the project and the team that brought it all together.

Of course MEM had a great install team with TL Shield & Associates taking charge of the placement and start up process. C. W. Driver led the way with the overall project leadership and they were grateful for our participation. “We appreciate MEM’s experience in the elevator industry. They helped keep the project moving forward and on time.” – John Kately, Project Executive, C.W. Driver. Lastly, KTGY provided superb architectural plans, drawings and concept.

It was a team effort with us playing just a small part of the overall effort and we are overjoyed with the results.

The project was a modular build from the beginning. So, using a conventional elevator can defeat the overriding premise of using the modular concept. Modular is supposed to be faster than conventional construction. There are other positive factors such as it being safer, greener, higher quality and more cost effective, but the first thing people look at is speed to completion.

We helped with the timeline because if you have a modular project with a conventional elevator, the work can easily grind to a halt. The elevator is smack dab in the middle of the critical path and conventional elevators interrupt the general construction process in the following ways:

For all the above reasons and more, for a modular project the only solution is to place the MEM Elevator solution.

The five-story development will offer studios and one-bedroom apartments on a 0.49-acre site. Residential services and a boxing gym will be located on the ground floor. The 98-unit building will be constructed around a central courtyard, providing privacy, safety, and a deepened sense of community. Parking spaces will be provided for social services staff while each resident will have a bike storage space. Floor to ceiling glazing along the amenity space will engage the community and brings movement to the street.

The elevator for the five-story project, as you can see in the video above, was set in no time. Quite impressive even for veteran project managers. “Seeing a fully installed elevator lowered into place and set in four hours was amazing.” – Luis Cadiz, Project Manager, C.W. Driver.

The process begins with placing the mode of conveyance, an in-ground hydraulic jack. It goes in first. Then the lower a portion of the fully installed elevator and hoistway gets craned into place. Once it is set, the second section of the elevator is lowered as well and locked in. The elevator came in two sections due to transportation needs and is not unusual in the least. The units are designed to be stackable.

The entire elevator set took less than four hours and everything is already inside including the elevator car and wiring. Once power is available onsite the MEM Elevator System is ready to go. It will then be started up, adjusted and scheduled for inspection. An easy, fast, timesaving solution. The elevator is off the critical path and the all too important purpose of the building can begin changing lives sooner than if a traditional elevator was used.

TL Shield & Associates set the elevator and will be in charge of start up as well. They and Modular Elevator Manufacturing was chosen due to the expertise they provide and the superior product they offer. They have been the leaders in the modular elevator field for more than two decades.

Tough steel makes up the MEM Elevator System hoistway with production occurring in a factory environment. Installation of all the elevator components and parts then takes place. Loading and shipping occurs next when the site is ready. In four hours you will have a fully installed, commercial quality elevator ready to be started up and used.

The mission of this project is important. The elevator and the Hope on Hyde Park project are crucial to combat the growing homelessness issues in Los Angeles. There are several benefits for supportive housing with the MEM system:

In conclusion as we see with Hope on Hyde, it maybe time to explore the possibilities further regarding supportive housing elevators. Let’s see if the MEM Elevator System can meet your needs. You can click the button below for a Fast Track Quote for a project you currently are working on. However, if you want to explore it more, request a LIVE VIRTUAL TOUR. We would be happy to pull back the curtain. We will show you how we produce the industry’s most successful modular elevator solution.

Elevator Revolution – It really is that easy. Projects are complex with lots of moving parts. Electrical, plumbing, heat and air, structural concerns, finishes, the foundation, openings, and more needs constant monitoring and adjustment. The logistics of all those construction divisions suck time and resources from your busy schedule. This makes keeping everything on track, on time and moving forward more than a headache to say the least.

So, every once in a while it is a relief when there is a simple solution. A solution that takes an entire part of the project off the critical path, instead of placing it on the to do list. The MEM Elevator System does just that and makes it easy. It allows you to draw a line through that part of the building project and not think about it again.

It is a simple solution because with a modular elevator there are only two steps once the contract is signed, the purchase made and the pit is poured. The first step is a fully installed elevator delivered and craned into place. This step takes less than four hours and none of your time unless you want to watch it go in. The second step is once permanent power is supplied, the elevator is started up. This take around a week. This was exactly the process of one of our most recent projects, Los Osos High School.

Projects like Los Osos High School demonstrate our fast, high-quality solution through forward thinking and superior engineering. See, traditional elevator companies and other modular elevator businesses have significantly less experience or are just stuck in old thinking when it comes to modular elevator systems. Traditional elevators are anchored in the 60’s (the 1860’s) with no desire to upgrade their product models. With the modular elevator business, many elevator novices jumped into the market with little understanding of what makes an elevator tick. As a result they have no idea as to why installations are such a pain and certainly had no idea as to how to find engineering solutions. For them, often times, each elevator produced is an experiment that the builder pays for in real dollars.

But why should superior engineering matter to the developer, building owner, architect, project supervisor, or other building professionals? I mean really the most you really need to know about an elevator is when you press the button, it goes up. In simplest terms an elevator is just a box that goes up and down inside another box.

However, the engineering matters because that is what allows the installation to go in smoothly and quickly without delays and complications. The process is a success because what we say about a simple solution is true. And it leads to a headache free jobsite. Also, because of our expertise and knowledge we are able to accommodate special requests and special circumstances. Others run from projects that need to incorporate a corner post, or difficult applications such as inside the Spruce Goose Hanger for Google. Because of our engineering, knowledge and experience we enjoy the challenge and the results.

This was true on the Los Osos High School project. Everything went according to plan and according to the timeline that was most beneficial for the project. As we all know, schools have a difficult timeline to say the least. Even when it is new construction the calendar of the school district reigns supreme. That brings lots of pressure to bear.

With the project a fully installed elevator was delivered when promised. And it was up and running on time with no complications. Wouldn’t it be nice to know that the elevator is taken care of completely? That is possible with success through engineering and our knowledgeable team.

We have a well thought out approach when it comes to durability, quality, safety, and speed. That is due to our decades of experience in the elevator industry in both service and manufacturing. We know the challenges so you benefit from our years of knowledge. Bottom line, we know what it takes to design and build one tough elevator. But beyond that, we deliver it when you need it on the jobsite as a fully installed unit. Here are some videos showing how easy it is.

So, for your next project it maybe time to explore the possibilities of the MEM Elevator System.

To see how our experience in the elevator industry can be a perfect fit click the button below. We can provide a Fast Track Quote or schedule a LIVE VIRTUAL TOUR of our facility. We would be happy to pull back the curtain and reveal our process. It shows how we produce the industry’s most successful modular elevator solution.

Hope On Hyde Park/Los Angeles, CA – Mission accomplished. The Hope On Hyde project is a great example of everyone pulling together for a great outcome. Our small part for this affordable transitional housing community for the Los Angeles area is complete. As a result we thought we would look back at the project and the team that brought it all together.

Of course MEM had a great install team with TL Shield & Associates taking charge of the placement and start up process. C. W. Driver led the way with the overall project leadership and they were grateful for our participation. “We appreciate MEM’s experience in the elevator industry. They helped keep the project moving forward and on time.” – John Kately, Project Executive, C.W. Driver. Lastly, KTGY provided superb architectural plans, drawings and concept.

It was a team effort with us playing just a small part of the overall effort and we are overjoyed with the results.

The project was a modular build from the beginning. So, using a conventional elevator can defeat the overriding premise of using the modular concept. Modular is supposed to be faster than conventional construction. There are other positive factors such as it being safer, greener, higher quality and more cost effective, but the first thing people look at is speed to completion.

We helped with the timeline because if you have a modular project with a conventional elevator, the work can easily grind to a halt. The elevator is smack dab in the middle of the critical path and conventional elevators interrupt the general construction process in the following ways:

For all the above reasons and more, for a modular project the only solution is to place the MEM Elevator solution.

The five-story development will offer studios and one-bedroom apartments on a 0.49-acre site. Residential services and a boxing gym will be located on the ground floor. The 98-unit building will be constructed around a central courtyard, providing privacy, safety, and a deepened sense of community. Parking spaces will be provided for social services staff while each resident will have a bike storage space. Floor to ceiling glazing along the amenity space will engage the community and brings movement to the street.

The elevator for the five-story project, as you can see in the video above, was set in no time. Quite impressive even for veteran project managers. “Seeing a fully installed elevator lowered into place and set in four hours was amazing.” – Luis Cadiz, Project Manager, C.W. Driver.

The process begins with placing the mode of conveyance, an in-ground hydraulic jack. It goes in first. Then the lower a portion of the fully installed elevator and hoistway gets craned into place. Once it is set, the second section of the elevator is lowered as well and locked in. The elevator came in two sections due to transportation needs and is not unusual in the least. The units are designed to be stackable.

The entire elevator set took less than four hours and everything is already inside including the elevator car and wiring. Once power is available onsite the MEM Elevator System is ready to go. It will then be started up, adjusted and scheduled for inspection. An easy, fast, timesaving solution. The elevator is off the critical path and the all too important purpose of the building can begin changing lives sooner than if a traditional elevator was used.

TL Shield & Associates set the elevator and will be in charge of start up as well. They and Modular Elevator Manufacturing was chosen due to the expertise they provide and the superior product they offer. They have been the leaders in the modular elevator field for more than two decades.

Tough steel makes up the MEM Elevator System hoistway with production occurring in a factory environment. Installation of all the elevator components and parts then takes place. Loading and shipping occurs next when the site is ready. In four hours you will have a fully installed, commercial quality elevator ready to be started up and used.

The mission of this project is important. The elevator and the Hope on Hyde Park project are crucial to combat the growing homelessness issues in Los Angeles. There are several benefits for supportive housing with the MEM system:

In conclusion, it maybe time to explore the possibilities further regarding supportive housing elevators. Let’s see if the MEM Elevator System can meet your needs. You can click the button below for a Fast Track Quote for a project you currently are working on. However, if you want to explore it more, request a LIVE VIRTUAL TOUR. We would be happy to pull back the curtain. We will show you how we produce the industry’s most successful modular elevator solution.

Early In Means Elevator When you Need It – Can you get an elevator when you need it? Including MEM early in a project means you can. Of course the alternative is the traditional way when the elevator company tells you, you can have it? But if you are tired of letting one industry dictate your construction schedule there is an alternative. The “alternative” has a long track record of success as the solution. It is also being embraced nationally by major construction companies, architects, design build firms, building owners and elevator installers.

The solution is the modular elevator and MEM is the leader of an elevator revolution with the MEM Elevator Solution. Make no mistake, modular elevators are the future. There is no doubting that. It is and will be a reality that very soon a modular elevator will always be the first option in any low or mid-rise application. They go in faster with fewer headaches and difficulties overall. The price is competitive to better and the components are largely the very same you will find in any other elevator. There is only one way that this growing trend will be up-ended and that is if modular elevator companies themselves don’t live up to the promises they make and the quality they market.

That seems to be what is happening at least to some extent currently. For instance, there is an often repeated 8 week delivery of an elevator. If a company makes that claim, be aware that there are dozens of caveats and requirements that cloud the numbers. We reject that marketing ploy and want to be included early on projects so we can deliver when you need the unit not at some inconsequential and artificial timeline.

So with the above all true, how can they make an unrealistic promise? It is, “Sell the elevator and pray for rain.” approach. They know in all likelihood that the early stages of the project will not go off without a hitch and the financing, ground breaking, permitting, site prep, foundation and elevator pit pour will be delayed. This gives them time to get the elevator done before shipping. At least that is their hope and why their fingers are crossed.

Ultimately, the promise of the eight weeks was never realistic to begin with and never is intended to be adhered to by the elevator company. Heaven help you if you are efficient run a tight timeline and the weather cooperates. Odds are if you believed the canard of eight weeks…the elevator will now leave you frustrated and sour on modular elevators. We see people hesitant to use modular for just that reason. Once a promise, even one as outlandish as an eight week elevator is broken, trust is hard to earn back.

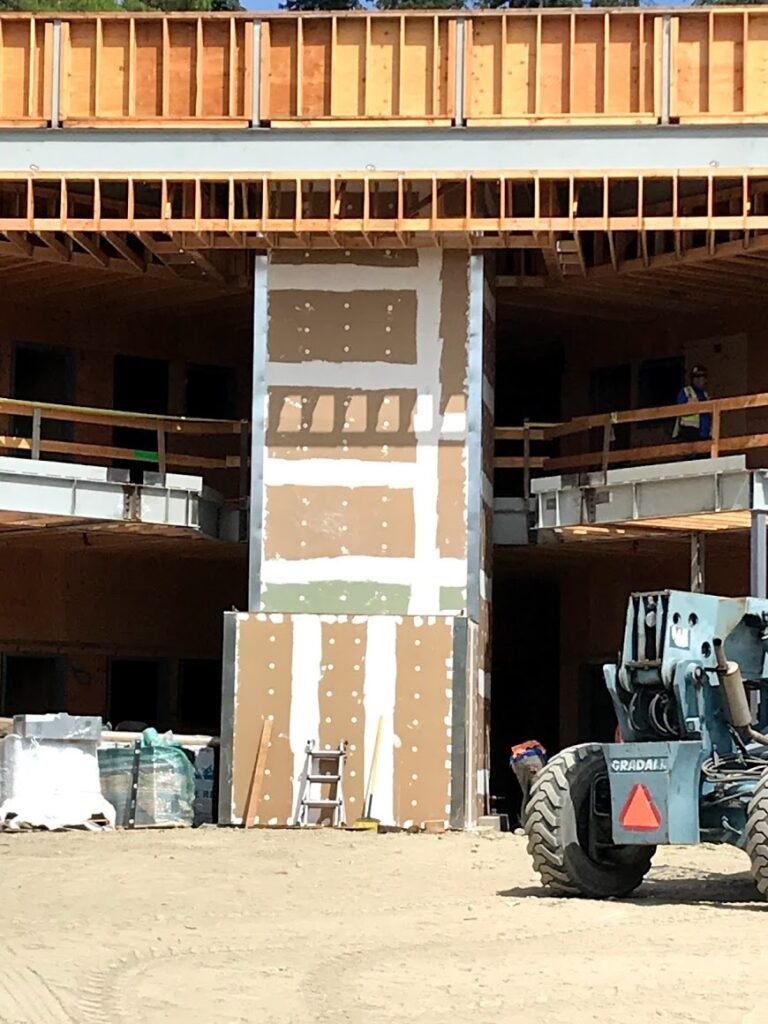

How is the MEM Elevator System different? We want to be early on the project so we can always deliver the elevator when you need it. There is no promise of a fictional and arbitrary timeline. We are honest from the beginning and listen to your needs. Then together we determine when it is best for the elevator to be delivered. We discuss if the elevator should be delivered first in the project, in the middle or the end. In the above photos, you can see it was determined that the elevator should go in after framing. Others go in first or last. We also discuss any special requests or specific difficulties to overcome. For instance our elevators are often used as a construction elevator to cut costs or for schools holding back the delivery date for a holiday or summer break.

The expected delivery date is then generated and the process begins. We know delivery dates fluctuate in every job, but having a general timeline for delivery is the best possible practice for the entire construction team. To keep things on track you have a personal contact that will touch base as needed to update the schedule. Everyone is always kept in the loop.

In our process while you are dealing with a million other questions about the project, permitting, figuring out subs and the rest of your project schedule we are ordering all the components, doing the paperwork, and creating the elevator schedule. With all that done and ready, the elevator is placed in our production line when it will be completed as you need it. It then arrives as promised.

This is truly revolutionary. No longer are you being told when the elevator will be finished. You have control back.

So to ask the question again, can you get an elevator when you need it. Yes you can, but MEM being early in is crucial.

If you are interested in the concept of a modular elevator and would like to find out more about the MEM Elevator System and our elevator revolution, you can have a Live in person or even Live Virtual Tour. Just click the button below. We would be glad to pull back the curtain and show you around. This will allow for you to see with your own eyes our concept come to life and answer any questions you may have.

If you have a specific project in mind just click the Fast Track Quote button below. It will get the process going and we will contact you with costs. Overall we strive to be transparent and willing to discuss your needs so we can provide a great solution. We look forward to working with you when you join the elevator revolution.

Shorten Elevator Lead Time – One the best kept secrets in the elevator industry is the timeline from a contract being signed until the elevator is delivered and then passes inspection. I am no conspiracy theorist, but it seems that no one wants to talk about the subject in the least. See for yourself. Go ahead, I encourage you to search for a source on any platform that tells how long the timeline is for a commercial elevator installation. I’ll wait…

So what are we to do if you want a general timeline for getting an elevator installed in new construction or even a retrofit application? It is kind of important to find out how long generally an elevator takes to install and get running, right? Now, I can tell you how long it takes for the MEM Elevator System, but as a rule in the elevator installing world that is a top secret. As a result, for that information we are stuck with general polling and anecdotal stories. The need for you to know that information is the lack of knowledge does not allow you to compare the facts of the install and puts you at a disadvantage when deciding on the elevator type and company.

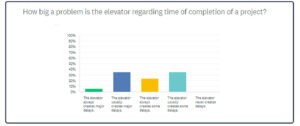

Now up front there is not a poll completely on point. However, there are a couple that can give some guidance. There is no denying the timeline when actually applied to projects is a huge problem in light of these polls. One of the polls of construction industry professionals found that 100% of respondents said the elevator “always created major delays” to “usually creates some delays”. In this day, when people rarely agree on anything 100% is astounding. But get this, 0% or none said that the elevator never creates delays. So why do so many respondents think there are delays? Because the timeline for completion is not accurate from the outset or one has not been established or taken seriously by the elevator company.

This result was replicated in another question in the same poll that asked, “What are the biggest difficulties regarding the elevator?” A full 82% indicated that delays in start up were the biggest problem. Am I crazy or does the elevator industry have an issue? Maybe both?

The results could be waved away if it weren’t for so many stories we are hearing from elevator installers, project managers, and building owners. Often they contact us or request a Fast Track Number stating the reason they called was because the lead times from the major companies were so long. They felt they were given every excuse in the book but no solution to delays. They mentioned production delays to manpower shortages as to why the expected delivery date and installation was over a year out. And the timeline for some has even been stated to be in excess of two years.

In an industry that is so slow to respond (as seen in this short video) what are customers supposed to do? Where can the buyers of commercial elevators find the answers they need? Where can they get a reasonable timeline? First, a quick examination of why the delays.

Having a hoistway built first and then sit empty until there is permanent power is lunacy. But this is the general way elevators are installed. Months tick by while nothing is done in a fully finished hoistway. Then once permanent power is provided the elevator installation company arrives. They take over and get in the way of every other trade filling a predetermined area with parts, pieces, tools, and components.

The reason for the need of power is that the elevator has to be operational to install the rails and clips as they use the elevator as a work platform. If the area is not climate controlled and the weather gets too cold or hot, they simply stop work. Try getting an elevator installed in the northern US or Canada without delays if you don’t believe me. An old saying is that in some climates the elevator installer watches the thermometer closer than the timeclock.

Meanwhile as every elevator component has to be carried into the enclosed hoistway and screwed, bolted or cobbled together work is slow, laborious and often unsafe. There is lots of heavy lifting and risk of dropping objects inside the shaft.

Only after all of the work is completed regarding elevator doors and entrances can other trades such as rock and tape crews, painters, flooring installers and exterior finish workers can return to finish the job. In most cases it means more delays usually unaccounted for.

Simply put it is a mess; a slow, plodding, inefficient mess. Beyond that, the completion time of the whole project hangs in the balance because the elevator is smackdab in the middle of the critical path. The elevator shouts, “None shall pass.” at the top of its lungs and the project grinds to a halt. All stops when one hoistway heaves with cold weather, one part is on back order, with one injury in a dark dangerous hoistway, one misplaced tool, one blown console, one little problem and the whole project grinds to an unforgiving halt.

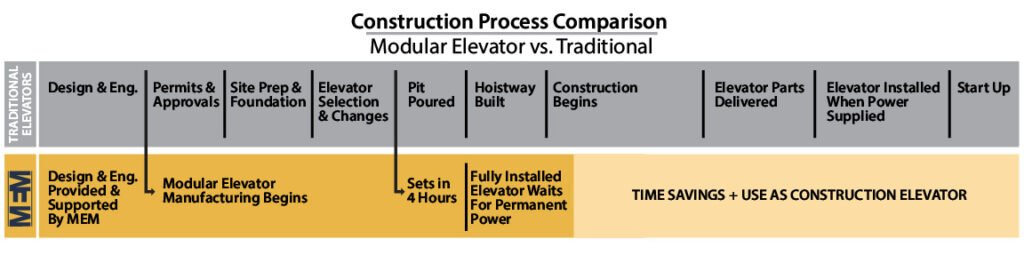

A better or revolutionary process changes the entire game. We provide an elevator when you need it not tied to the old fashioned practices. In the chart below you can see how we are different.

The traditional elevator process is linear and mired in design and engineering of the hoistway, to gathering up all the parts and components. Our system is not. The MEM Elevator System is delivered hoistway and all, fully installed. It is placed in a couple hours and can be started up in as little as a week. We start with the day you need it and then count backwards in days to place it our production schedule to be be delivered on time every time.

It is so fast in delivery and set in just a couple hours, that it is often used in lieu of a construction elevator on some projects saving even more time and costs. When modular units are built in factories, the time is simply shortened. But what is not incorporated in this chart are the ancillary savings and benefits.

More and more builders and building owners are joining the revolution. They are exploring what modular has to offer and how the modular timeline can be a huge benefit.

Our MEM Elevator System is beneficial for the whole project and the results are stunning especially when taken of advantage of in full. Can you imagine how your project would change if you could determine when your fully installed elevator arrives? Then started up in less than a week? Or realizing it goes in so fast it often doubles as the construction elevator on the job? That is a game changer, especially in current times where every penny counts.

So now is the time to act if you have any questions about modular elevator or the MEM Elevator System. If you are the least bit curious about Modular Elevator Manufacturing just click the button below. You can get a LIVE VIRTUAL TOUR of our factory. We will pull back the curtain and let you look at our process and how we are leading the modular and elevator revolution.

Do you have a project in mind? To get thumbnail numbers to consider, just click the Fast Track Quote button below. We will be in touch in less than 24 hours. At that time we will give you an idea of how your project will be improved and your investment. You will also find out what it takes to make a change for the better.

Hope On Avalon/Los Angeles, CA – When it comes choosing the elevator type for any job, Modular Elevator Manufacturing will help. We are not a one size fits all elevator company, trying to shoehorn projects into a singular kind of elevator. Also our vast experience and knowledge helps guide during the project in making the best choices.

That’s the case at our current elevator jobsite at the Hope On Avalon project in Los Angeles. On that project we partnered with Ed Grush – project general contractor, KTGY – project architect, Silver Creek Industries – modular supplier and Danny Moizel at HGB Modular – consultant. Working with that group is like working with the dream team of construction and all were a joy to work with. They are each knowledgeable, experienced, have well run organizations and are leaders in the construction industry and modular industry as well.

They came to us needing a 5-story elevator for a transitional and supportive housing project. The solution was a stackable hoistway and an in-ground hydraulic jack. Setting the fully installed elevator was complete in just a couple hours. We were glad to be a part of the project.

Using an in-ground jack was the best solution for the project. It has a fast, smooth ride that will serve the purposes well. The cab is made of tough Galvaneal steel with vandal resistant hall calls and buttons. It will handle the rigors of service for decades. We do not use wood core or particle board with the MEM Elevator System. Galvaneal reduced mold issues, chipping, breaking and warping that can occur with wood core cabs.

As you can see in the video, the hoistway is built with tough 4X4 inch steel meeting all requirements. All the elevator components are installed and then it is wrapped in drywall ready for cladding. The elevator and jack arrive on a truck and then the in-ground jack is simply lowered into the pre-drilled hole. The elevator bottom section is placed on top. Then, the upper section is lowered in the same way and connected. The right elevator for the right job. Fast and ready for electric and start up.

The mission of this project is important. The elevator and the Hope on Avalon project are crucial to combat the growing homelessness issues in Los Angeles. There are several benefits for supportive housing with the MEM system:

In conclusion, it maybe time to explore the possibilities further regarding supportive housing elevators. Let’s see if the MEM Elevator System can meet your needs. We would love to be a part of recommending an elevator type that suits your project best. You can click the button below for a Fast Track Quote for a project you currently are working on. However, if you want to explore it more, request a LIVE VIRTUAL TOUR. We would be happy to pull back the curtain. We will show you how we produce the industry’s most successful modular elevator solution.

Hope On Hyde Park/Los Angeles, CA – MEM Experience paved the way for participation in this worthwhile project. When looking at elevator options, several considerations were made, but the experience of MEM (Modular Elevator Manufacturing) and TL Shield & Associates as the onsite elevator team paved the way for this exceptional project. MEM is proud to be a part of this project with C. W. Driver and they are grateful for what we bring to the table. “We appreciate MEM’s experience in the elevator industry. They helped keep the project moving forward and on time.” – John Kately, Project Executive, C.W. Driver.

Why are we so proud? Hope On Hyde Park is a big deal as a modular project but also due to the building’s mission. The project uses locally fabricated modular building units, including a state of the art, easy installing MEM Elevator System. This will create a modern and affordable transitional housing community for the Los Angeles homeless population.

The five-story development will offer studios and one-bedroom apartments on a 0.49-acre site. Residential services and a boxing gym will be located on the ground floor. The 98-unit building will be constructed around a central courtyard, providing privacy, safety, and a deepened sense of community. Parking spaces will be provided for social services staff while each resident will have a bike storage space. Floor to ceiling glazing along the amenity space will engage the community and brings movement to the street.

The elevator for the five-story project, as you can see in the video above, was set in no time. Quite impressive even for veteran project managers. “Seeing a fully installed elevator lowered into place and set in four hours was amazing.” – Luis Cadiz, Project Manager, C.W. Driver.

The process begins with placing the mode of conveyance, an in-ground hydraulic jack. It goes in first. Then the lower a portion of the fully installed elevator and hoistway gets craned into place. Once it is set, the second section of the elevator is lowered as well and locked in. The elevator came in two sections due to transportation needs and is not unusual in the least. The units are designed to be stackable.

The entire elevator set took less than four hours and everything is already inside including the elevator car and wiring. Once power is available onsite the MEM Elevator System is ready to go. It will then be started up, adjusted and scheduled for inspection. An easy, fast, timesaving solution. The elevator is off the critical path and the all too important purpose of the building can begin changing lives sooner than if a traditional elevator was used.

TL Shield & Associates set the elevator and will be in charge of start up as well. They and Modular Elevator Manufacturing was chosen due to the expertise they provide and the superior product they offer. They have been the leaders in the modular elevator field for more than two decades.

Tough steel makes up the MEM Elevator System hoistway with production occurring in a factory environment. Installation of all the elevator components and parts then takes place. Loading and shipping occurs next when the site is ready. In four hours you will have a fully installed, commercial quality elevator ready to be started up and used.

The mission of this project is important. The elevator and the Hope on Hyde Park project are crucial to combat the growing homelessness issues in Los Angeles. There are several benefits for supportive housing with the MEM system:

In conclusion, it maybe time to explore the possibilities further regarding supportive housing elevators. Let’s see if the MEM Elevator System can meet your needs. You can click the button below for a Fast Track Quote for a project you currently are working on. However, if you want to explore it more, request a LIVE VIRTUAL TOUR. We would be happy to pull back the curtain. We will show you how we produce the industry’s most successful modular elevator solution.

You learn a lot by listening. Like mom always said, we have two ears and just one mouth for a reason. So, last week at the World of Modular conference held by the Modular Building Institute we got a chance to listen.

We found out what people were thinking when it came to elevators from their perspective. How does the architect, engineer, project manager, owner or designer really feel about elevators and the elevator industry? And especially what do they think of modular elevators.

Well let’s be blunt, we did not hear many positive things about the elevator business as a whole. Some folks actually joked we were the most hated industry at the conference! Wow tough crowd. But I can see why.

See in simplest terms people in the construction industry know an elevator is just a box moving up and down inside another box. You have a cab, a hoistway or shaft, doors, a control system and a means of conveyance. Pretty simple. But, when it comes to making all of the intricate pieces of the puzzle to work together in a project, that is the hard part. And thankfully that is our specialty with experience and knowledge with decades in both the elevator and construction industry.

Unfortunately, though many have been led to believe (by elevator folks) that the elevators are the difficult part of the equation. Couple that with a reputation for unresponsiveness and you have a recipe for agitation and mistrust. Hence the negative comments about the elevator industry.

Overall we got much higher marks for the MEM Elevator System and innovation, flexibility and responsiveness. Those we spoke to realize we are different from others in the elevator business and that even high-quality modular elevators are relatively easy…it is the project integration that is complex and that is where we have an opportunity to shine.

So why are things seemingly so cloudy and murky in the elevator end of the business? Why all the hate? There are several reasons and believe it or not it often earned and not all an evil plot (just some of it is).

The Modular Elevator Manufacturing Elevator System is different. When you are talking to someone about an elevator at MEM, you are talking to the project manager. Your elevator is not going to be passed around like a hot potato. Also, from the outset your elevator and your project are combined. That means one person is working on the details.

So the World of Modular conference presented by the Modular Building Institute was a learning and listening experience. We hope that we were able to hear what you were saying and you see us as your elevator solution. MEM is doing things differently and is starting an elevator revolution where easy, fast installs are the norm and all the details worked out ahead of time. Is it time for you to join the revolution? It is never too late.

As you make your elevator choice remember the MEM System is perfect for any low or mid-rise application and it is very easy to set and start up as we take care of the heavy lifting.

The MEM System is commercial quality elevators installed when you need them in about four hours. They can be started up once we have power and can be used as a construction elevator. Also, they are not just for modular building. Any type of structure can utilize our elevators as a way to get quality installed quickly and off the critical path.

It is time to change how things are done and seriously consider modular. The Modular Building Institute is a great resource if you have questions in general. Or if you would like more information about us specifically and how we can ease some of your elevator pain points feel free to contact us. If you have a project in mind, to get the ball rolling just click the Fast Track Quote button below. You can also see how we produce our elevators with a Live Virtual Tour of our facility. We would love to show off a bit so sign up today.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.