We need Supportive Housing Elevators Fast. Supportive housing is also referred to affordable housing or low income housing, but regardless of the name the need is more than evident. So, when it comes to housing the homeless, faster is better to address the issue. But also we must use the resources available in a timely fashion. Funds are being allocated to help right now. As an example the Los Angeles City Council has approved more than $51 million in financing for the construction of new affordable and permanent supportive housing developments.

But that funding can be slippery if not acted on quickly and the need could continue to go unaddressed if not used. The bottom line is that funds allocated need to result in actual building projects that are designed for housing the at risk population as quickly as possible.

And there is the problem. As everyone in the construction industry knows, a building does not pop up overnight, even when funding is approved and support is given. It takes plumbing, electric, foundation work, drawings, permits and approvals. Lastly, if over one story the project takes the slowest component of any build project, an elevator. But Modular Elevator Manufacturing (MEM) has the solution.

Elevator Sales Executive – Christian Lahud from TLShield & Associates explains, “In traditional construction the elevator hoistway is built and sits until power is turned on at the end of the project. Then and only then elevator technicians show up. They come and go at their leisure, carrying in elevator parts and installing them one at a time until the elevator is running.” Lahud went on to say that, “The elevator and its mechanics are the first on the site and last to leave. Everything is slowed down including other trades that need the elevator installed to finish.”

The MEM Elevator System however is produced in a factory environment where a hoistway is constructed with steel. The structure is engineered to be strong enough to be self-supporting in most cases. Then all of the elevator components are installed in the hoistway in the factory.

Ultimately, when it is needed it is loaded on to a truck, shipped to the jobsite and set in place. In four hours you will have a fully installed, commercial quality elevator ready to be started up and used. It can also double as a construction elevator.

Lahud says this makes MEM perfect for the affordable housing market. “The MEM Elevator System is high-quality, but fast in setting and startup. It is a real solution where speed is of the essence to address a pressing need. No other elevator system is shipped and in place when the customer wants it.”

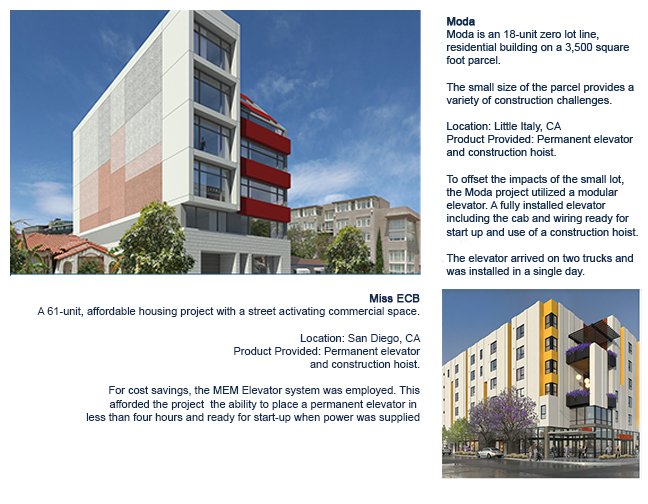

How do we know we are the solution? Over the decades of experience we have produced several elevators for supportive housing with just a couple of the most recent projects pictured. As you can see, whether a steel frame structure or modular structure involving storage containers, the MEM Elevator System is a perfect fit. We can be what you need regardless of the structure type. Right now due to the speed of modular construction and the immediacy of the problem there seems to be a high demand for modular structures. But another fast way to build housing is using an existing structure.

With that in mind, we are perfect for retrofit opportunities. The initial purpose of the modular elevators was to attach them quickly to exteriors of existing buildings to make them more accessible. We have grown from servicing just that market over the past 30 years, but we are still experts you can rely on if you have a retrofit project in mind.

Wrapping it all up the benefits are obvious:

It maybe time to explore the possibilities further regarding supportive housing elevators and see if the MEM Elevator System can meet your needs. You can click the button below for a Fast Track Quote for a project you currently are working on. However, if you want to explore it more, request a LIVE VIRTUAL TOUR. We would be happy to pull back the curtain and show you how we produce the industry’s most successful modular elevator solution.

I just finished writing a great blog about how Modular Elevator Manufacturing (MEM) is in complete in support of the Modular Building Institute (MBI). Also, included is how we support the modular building industry as a whole and promote the benefits of modular construction. We are even going to the MBI annual convention (see more below)! Then I realized that many could confuse our support with use of our elevators. To be clear and to set the record straight, our MEM Elevator System is compatible with any structure type.

The ability to be compatible, depending on the height, is that MEM elevators are designed to be self-supporting. That means they can be place on the interior or exterior of buildings. Regardless of the construction method used MEM is a fit. Everything from post-and-beam construction to heavy steel framing can use a modular elevator. Even concrete structures can and do incorporate modular components, including the MEM System.

In real terms there is no difference in the use or components in a traditional or a modular system. Our commercial quality elevators are just that, high quality. Modular is just superior. The MEM System provides a fast, high-quality solution that allows you to decide when the unit arrives. When you need it, it is delivered. An elevator shaft lowers into place with a factory installed elevator inside and ready for start up.

Another application that traditional elevators really struggle with are when it comes to retrofit projects. They are a piece of cake for us. Modular elevators are used in additions to structures, exteriors of existing buildings, stadiums and also in the center of existing buildings. And, it is not as hard as it sounds. The good news is that we have had decades of experience. With our help you can determine the best way to place the elevator regardless of the structure type. To assist we will not only provide you with drag and drop drawings, and engineered plans but expert advice. With our system and our help you will accomplish your goals for your project.

Now let’s be clear there are some limitations. MEM elevators are engineered for low and mid-rise applications. Also, depending on the location of the build, there may be some issues with crane use or getting under bridges. But, those are usually minor problems and usually we find ways to circumvent almost any challenge. Here’s an example.

So is the MEM Elevator System perfect for modular building? You bet. But, our elevators are utilized for almost every structure as well.

If you want to find out more about our system you can come and see us at World of Modular. We would be glad to speak with you about the benefits of modular and how our elevators are leading a revolution in construction. This year the conference is in San Antonio, Texas – April 25-28, 2022. If you go (and we highly recommend it) make sure and stop by booth #4. There you can discuss the elevator revolution with our national territory manager Ken Grider.

He will be able to answer any questions you may have and give you a thumbnail price on the spot. If you just can’t wait for the show, you can contact us below for a Fast Track Quote. This quick quote will give you all the pricing information you need to begin your project. You can also sign up for a LIVE VIRTUAL TOUR of our production facility. During the tour you will see how we produce the highest quality modular elevator in the industry. We will take any and all questions about MEM while we show you what we do. Find out how we are taking the elevator industry higher.

Elevator cuts costs as inflation rises. Inflation is not just a term thrown around by the Wall Street crowd or economists. Inflation is very real, very damaging and turns out not transitory (whatever that means). As the January numbers reveal inflation is with us. And an economy does not shift at a whim especially when the all the forces are aligned for inflation and the social psychology for it has set in. The ripples are felt throughout the nation in every home and every sector.

That is especially true in the construction industry. We are engage in long-term commitments and obligations with slim margins. That puts more pressure as we build, meet payroll and see operating costs explode. Suddenly, we grasp for every potential savings available by trimming general costs and seeking alternatives. Surprisingly, the elevator cuts costs as inflation rises, but only if you choose the right alternative.

The right alternative is a commercial quality elevator that has a long-term history of success and that can replace the need for a construction elevator on the jobsite. By consolidating the tasks of a permanent elevator and a construction hoist, costs can be significantly reduced. But, only an elevator fully installed at the beginning of the project and ready for start up early on can meet the need.

This month’s project spotlight is really several projects, but two in particular that we just finished installing where the permanent elevator doubled as the construction hoist. Not having to employ a construction elevator can reduce costs immensely. This option is not just a way to save during inflationary times, but just smart business.

In both cases the elevator unit or MEM System was in place early in the project. The system can be engineered to be self-supporting, so it is placed and awaits power, set up and inspection. The set up portion of the project is usually less than a week in total hours. This makes it not only plausible to save significantly, but a certainty of reducing costs.

The Miss ECB project fully demonstrates the time and costs savings. As you can see it operates just like any other construction hoist with a set call box for access. Finish protection is key. Protective panels and wraps are in place during the build. You can also see that it is not a project dependent on any one type of construction method. the MEM System is at home in modular construction to stick built applications.

You can see there are two sections as pictured above. They are stackable units that make up the hoistway. The entire process took less than four hours to set. As a result, the fully installed elevator through the MEM System was ready for start up and inspection once power was supplied.

If you want to find out more about how choosing the right elevator cuts costs click below. You can either get a thumbnail budget number for the MEM System for your next project or, your can schedule a live virtual tour. During the tour we will pull back the curtain, so you can see how we produce the best elevator solution for all mid and low-rise applications.

Record Breaking Year Thank You! – This time of year we cannot help but to look back and see what there was to be thankful for. That at first blush it seems like a difficult chore because 2021 started off rough. Need I tell anyone that? It all began with a continued COVID-19 threat with its evil cousin Delta soon raising its ugly head. There were riots and dissatisfaction. Political problems and the rise of big tech. Inflation worries and supply chain woes still abound. The threat of manufacturing slowdowns even has Christmas looking more like one that Scrooge would approve of, before his reclamation. And yet somehow through it all two momentous earthshattering realities set in.

First, and I hate to say it, but in 2021 Tom Brady proved beyond any doubt he truly is the greatest quarterback of all time. This website that tracks his every success confirms it whether we like it or not. His stats are crazy and he is running out of fingers and will soon have to use his thumbs for all the rings he’s acquired.

Secondarily, and much more importantly I am glad to report, Modular Elevator Manufacturing broke all records for any modular elevator company. That makes us the premier modular elevator manufacturer anywhere. By producing more turnkey, commercial quality elevators than anyone else it qualifies us as the G.O.A.T. of modular elevators if you will. And just like with Brady, MEM’s success takes more than just us.

A company, any company, could not have our kind of success unless it has loyal friends, colleagues and customers (new and old) in ever-growing numbers. We appreciate you and are thankful for you. Too often the shoe of gratitude is on the other foot and we sometimes forget to say thanks as often as we should. Just today we received a great note from a brand new 2021 partner. It said in part:

“As a new trade partner we appreciate your expertise and innovation in pre-fabricated modular elevators.”

Those are rare words. When was the last time that you send a note of thanks to your elevator provider?

Therefore, in this season of recounting what we are thankful for, we here at MEM can say without hesitation we are thankful for you! We thank you for giving us the opportunity to serve you and provide you with a great product. We thank you for sticking with us during this turbulent past couple years. We thank you for exploring your options and taking the chance to break away from the old traditional ways of building for new and better. We thank those that have been partners for decades to those that have just discovered us.

We thank you! Happy Thanksgiving!

6 Reasons Modular Quality Matters – We have all been frustrated by low quality. Items purchased in good faith sometimes seem to break before they come out of the box. Or once out of the box, they look or perform nothing like what was pictured or promised when we bought the item. Instead of being happy with the purchase, words like cheap and flimsy cross our lips, meaning that we have been had. The more expensive the item, the more remorse follows.

However, in the modular industry quality is high because we take an antiquated process where onsite construction is the norm and move it to a production facility. What was then built by various people, in various trades, in various conditions becomes an orchestrated symphony of production. Historically poor quality and high cost is moved to a factory where exact processes and standards can be measured and accomplished. The modular process takes various acts of individual quality to a habit of success. For instance, our factory produced hoistways are always plumb and level. That is simply due to our factory processes that cannot be accomplished on the jobsite and it shows.

“Quality is not an act, it is a habit.”

Aristotle

As Aristotle said, “Quality is not an act, it is a habit.” And those habits are formalized into higher quality with modular manufacturing. In modular building you will never hear “close enough” or “I guess we will have to make it fit.” It is right every time, because the habits that produce quality are built in.

Unfortunately, there are outliers in some manufacturing facilities. Quality becomes just a slogan. If modular quality matters why do some not improve quality? Procedures are skipped, shoddy workmanship is allowed, new practices are slow to be adopted or worse continued tinkering and “problem solving” doesn’t allow for systems to work. In other words, if you have a team of problem solvers constantly changing the system in an unorganized fashion, the quality will undoubtedly suffer.

At Modular Elevator Manufacturing we make sure changes to procedures are checked and double checked before becoming standard operating procedures because modular quality matters. One person cannot just change something at a whim, even if it is generally a good idea. The procedure must likewise be changed with the whole team being aware of any alterations. That is where habits of quality are formed for the whole organization.

We agree with the Phil Crosby philosophy of quality and as a literal rocket scientist he knew a thing or two about it. He said, “Quality is the result of a carefully constructed cultural environment. It has to be the fabric of the organization, not part of the fabric.” Quality is not posters, or slogans or bright ideas that get used once and then forgotten.

For us quality is a top-down effort and philosophy emanating from senior leadership and permeating the organization at every level. Quality is crucial and should matter that much at every business. It does at Modular Elevator Manufacturing where we take quality seriously.

With that said here are the 6 reasons quality matters for us at MEM. There are probably more but these came to mind:

The entire premise of modular construction is that by instilling factory processes into the construction trade, the industry can produce a higher level of quality, faster and often at a reduced cost. That is what we do at MEM day in and day out. However, when slipshod practices and lack of experience infiltrate the market, quality declines. Then the premise of factory production being better comes under attack.

Whether due to ignorance, no experience or a desire to make a fast buck, when quality is ignored the reputation of the industry gets sullied. The result is a better process that produces a better product (safer, greener and faster) becomes more difficult for the consumer to accept. Who knows how many dollars, how much time and how much energy has been wasted. How many injuries could have been avoided? All due to a very small number of businesses that do not see quality as important.

That is why at MEM we do not think “close enough” is good enough. We know that low-quality has a cost to the industry, the customer and to safety. We strive for quality in all we do. Whether you need a multi-family unit elevator or one for a medical facility, an elevator for a retrofit project or new construction we provide a quality solution.

If you have tried modular elevators before and found that the quality was not as promised, don’t give up. Instead give MEM a try. We live by the above list of 6 reasons modular quality matters. You will not be sold a bill of goods for a fast buck, but instead you will find a partner providing quality you can count on.

If you have a project in mind just click the button below, we can get you budget numbers in less than a day. Of course you can also call us anytime, and have a real conversation with an expert in the elevator industry. We are looking forward to talking to you. You can also click the link for a tour of our facility. Also, we are proud of what we do and how we do it. So, if you are curious schedule your live virtual tour today.

“Elevator” and “delays” are two words you should never read in a headline. But in Abilene, Texas that is exactly what happened. The editors of the Abilene Reporter News were a little more creative than most by declaring, the school was “hoping to avoid the shaft” but you get the drift. Unfortunately, elevators delaying construction is far too common across the nation yet wholly unnecessary. There are more modern approaches to elevator installation that eliminate costly delays. You just have to avoid out of date construction methods.

The news article clearly points out why the elevator industry is moving past onsite installation. Schools like Austin Elementary deserve a better process.

People now realize that placing the elevator installation last in the process is fraught with problems and potential delays. This is precisely what happened in this Texas school. The timeline of the project had to be altered.

In this particular case all the other construction was generally completed with minor touch ups and landscaping left to go.

Then the elevator company decided to order the various parts and pieces. Seemingly the crates of components were delayed somehow. But, with the elevator installation at the end of the build, delayed ordering is only one possible stumbling block. There are several potential pitfalls that must be avoided to keep the project on time.

Just as likely a delay can be caused by damaged materials, crates being sent to the wrong address or missing parts. Not to mention materials being damaged during the elevator installation process itself. This can easily happen because onsite installation means that everything in an elevator shaft has to be carried in one piece at a time and then screwed, coerced, and cobbled together.

This all happens in a tight and crowded shaft. It makes no sense at all to do it that way, but that is the process.

Because some of the parts, like rails, are extremely heavy a dropped one can damage more sensitive components. Keep in mind damage does and will occur during the installation. Parts will be broken. It is just a question of if the parts can be easily replaced or hidden from view. That is not to mention all the injuries that can occur due to the manual lifting involved, falling or getting stuck between the various panels and the walls of the shaft. This bogs the crew down.

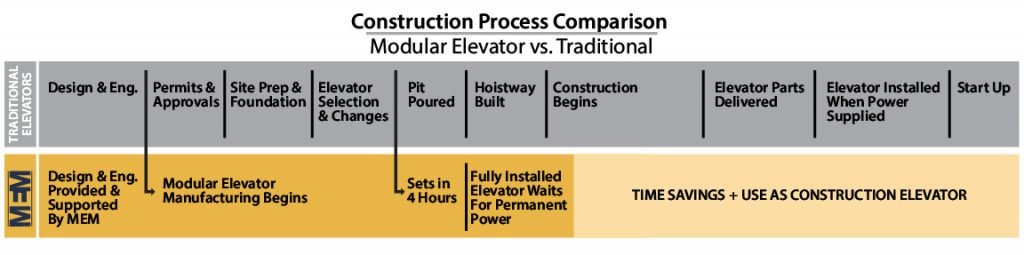

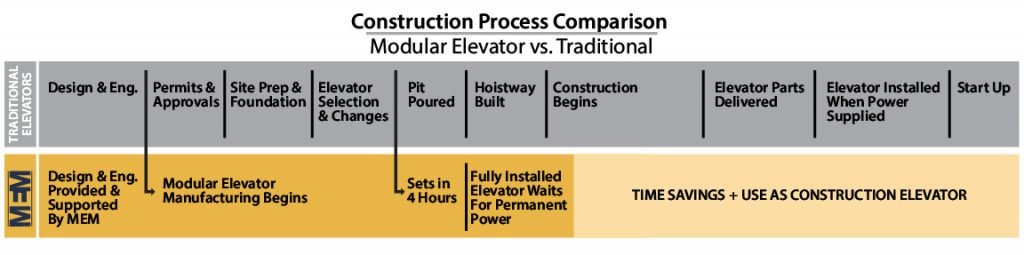

The solution is to have a more up to date installation processes in a factory setting. Then the elevator could be set in place first, avoiding any possible delays. This also cuts the timeline for the entire project. You can see the difference in the chart below. It lays out the difference between the traditional elevator process in gray. And the MEM elevator process in gold.

As you can see it is better to install in a factory, with no heavy lifting and all the parts are readily available. When the project manager wants it the elevator arrives. In less than four hours a fully installed elevator is in place.

Also, if you desire it can be used as a construction elevator.

This process produces higher-quality elevators with factory production that allows for consistent quality control and inspections. The improved process is simply faster, greener and smarter.

Lastly, old-fashioned elevator companies haven’t changed their process since the Civil War. It is that outdated, dangerous and often causes costly construction delays.

Our system has been revolutionizing the elevator industry for over 20 years with a success rate of 100% and hundreds of units in operation. So, the superintendent was mistaken when he said “There are only two companies in the world who do elevators”. Now an educational facility, commercial property, medical facility, parking garage or housing unit can have a fully installed commercial quality elevator delivered when they want. Options are no longer limited.

If you are the least bit curious about our elevators and have a low to mid-rise project in mind, click the Fast Track button for a thumbnail budget number. If you want to explore more, schedule a Live Virtual Tour of our facility. We will show you how we manufacture a high-quality elevator that sets in four hours and starts up in a week.

A free elevator is a dream for many. Let’s face it, elevators are generally expensive if you want a good one. However, if you sharpen your pencil and your perspective you can find vertical transportation that provides enough savings to make even the highest quality elevator significantly less expensive.

But, to start the hunt for a free elevator you have to begin with a question. What in real terms makes up a commercial quality elevator that you find in any building project?

Well, in most basic terms it has to have an elevator car, rails for the car to ride up and down on and a hoistway the rails are attached to. That skeleton then has to have a heart. The heart is the conveyance system that makes the car raise and lower as well as open and close the doors at each floor. After that, to carry the analogy further, it needs skin. A great looking interior to the car with lights, buttons, hall calls and handrails. The hoistway can also be part of the skin in the form of a glass elevator and decorative finish or just a painted surface. That is what an elevator is in its essence.

There are two processes to accomplish the above:

The differences in the finished product of the two elevators are negligible (other than quality) as most of the component come from the very same supplier companies regardless of the process. Whether you are buying a modular elevator or have an elevator installed onsite each has the same pieces or the components have been through the same rigorous approval process. These two systems produce generally the same elevator.

So if the products are largely the same and roughly the same cost, how do you get one for free with modular, but not traditional?

The answer is found in the savings that you can obtain because of the modular nature of the MEM elevator. The chart below explains the process for both. The traditional elevator is significantly different by the nature of how they are installed. They take much longer to cobble together on your jobsite when they want. There is design and engineering, followed by permits and approvals, site prep and the foundation and inevitable changes. Finally when the pit is poured and construction begins, the traditional elevator company lurches into motion.

They order parts and make sure logistically all the pieces and tools are dumped on your site with you contractually responsible. Then they start the installation process most usually after power is turned on.

MEM (the gold row) on the other hand arrives when you want. It takes the design and engineering that we have partnered together on and begins manufacturing. By the time the pit is poured the fully installed elevator is ready to be set in place. That takes about four hours (no kidding). As unbelievable as it may seem, you have a fully installed elevator sitting onsite waiting for power. Then when you are ready to have a fully functioning elevator turned on, we make sure it is started up properly. It is really that simple.

The traditional or old-fashioned way of putting in an elevator is at the end of the construction process. This throttles the completion and this is not idle speculation.

A thesis and study put forward by the Penn State College of Engineering supports this contention. In an actual parking garage construction sequence of a five-story project it was found that the elevators took a crazy 58 days to complete. Also, they were the last trade to get started other than landscaping and parking lot striping. They were also the last trade to finish. Now imagine changing that number of 58 days to ten, putting the elevators in first and using it as a construction lift like we did at San Jose State.

The date the parking garage opens comes sooner as the job closes faster. This reduces overall costs in addition to other benefits. No more making space for storage of all of the parts and pieces. Big sections of projects are cordoned off for this purpose. That slows the project. Not to mention all the coming and going with a big carbon footprint. Also they are burning your electricity to install the elevator. MEM’s elevator comes pre-installed.

Lastly, with a modular elevator once power is on and adjustments are made, you can use it as a construction elevator.

So now sharpen your pencil and put a dollar sign beside each item listed below. How much is it worth that:

As you can see with the above list and a sharp pencil you can save ten of thousands of dollars or more by using MEM elevators on every low and mid-rise project. The general conditions alone can run tens of thousands per month. So when you balance the costs and savings, you can have a higher-quality elevator installed when you want for less.

Is the elevator really free? Nope, but the savings you will gain using an MEM elevator will often be more than your investment. Not to mention the faster occupancy rate that has as an additional benefit. I was once thanked for trimming months off a project putting more money in the investor’s pocket on a hotel project.

So summing it all up isn’t it time to at least consider a modular elevator for your next project? To get the ball rolling all you have to do is click the Fast Track button below. The form asks a few easy questions and then we will contact you with an obligation-free budget number. If you want to do a little more research join a Live Virtual Tour of our facility to see how we produce the highest quality commercial elevator that installs in hours. Just click that button to get on the schedule.

Here is a short time-lapse video of a modular construction project that incorporated two of our modular elevators. The first is on the right side of the screen at :24 and the second on the left side of the screen at :59. The second elevator was also used as the construction elevator on the project. That saves time and money.

This fantastic project is by our friends at Pacific West Builders. They are national pacesetters in the modular construction industry. And MEM is the leader in the modular elevator industry so it was a seamless match.

MEM has more experience and higher skilled personnel than any other. We provide quality – consistency and simplicity for every job we do. If you contact us you will see the difference we make.

Whether you have a modular construction project or any other type, if you want the safer, faster, greener and smarter alternative click the button below. We are perfect for all low or mid-rise projects. Also, you can now schedule a LIVE VIRTUAL TOUR OF OUR FACILITY!

Here is just a real quick video on our last installation. In this particular project multiple elevators were requested. We placed 2 fully installed elevators in about 4 hours.

Amazing!

MEM is the leader in the modular elevator industry with more experience and higher skilled personnel than any other. We provide quality – consistency and simplicity to every job we do. If you contact us you will see the difference we make.

If you want the safer, faster, greener and smarter alternative for you next low or mid-rise project click the button below or contact us.

When you get over a couple of stories in a building project a man lift or construction elevator becomes a reality. Numbers bear it out even if it is a requirement based on number of stories. The need is there due to the cost of having a construction team without one tromping up and down stairs all day. Workers are simply less productive, so although the cost is often hidden in hours lost by using a staircase, it is real and real expensive.

But, then you have the added cost to your project for the temporary elevator, plus availability, the set up and inevitable delays. It seems you are either paying too much for the savings if you get one or you simply don’t have a construction elevator onsite at all because for a low or mid-rise project it seems cost prohibitive. So, here’s the question: Why use a temporary construction elevator at all when a permanent modular elevator could be used instead?

It makes perfect sense. A commercial quality, modular elevator can be placed and turned on when electricity is available at the jobsite. When construction is finished, it becomes the permanent elevator.

Now before I get started, let me say up front that this is not the perfect solution for every job. If your desired use is not a low or mid-rise project it is probably not a good fit. We are simply not the best solution for high-rises.

Also, if you are wanting to move tons of palatized materials, likewise we are not a match either. Elevators designed for passenger use usually have a capacity of between 2000lbs and 5000lbs. We, of course, can make elevators that have a huge capacity weight-wise, but the cost would outstrip the benefit once the building is opened.

In addition, passenger elevators are limited in size generally. First, you have the cab size. We can make elevators with a cab big enough for a hospital bed (the only limitation is getting elevators under the overpasses on a flatbed truck). But then you have the door issue as well. Usually, passenger elevators have door openings of 36 or 42 inches, although some can be wider. Keep in mind the door opening does not extend across the entire elevator cab. So, if you want to take items to the top floor larger than the cab or the door opening our elevator is not the best way.

There are plenty of other solutions that do not involve an elevator at all if moving big, heavy items is needed. But in most construction scenarios we are the solution or at least worthy of consideration.

I like to say that this blog is designed to be informational and not just a sales pitch. The above is exhibit A of just that. Shoehorning us into a project where it is not a solution makes no sense and damages our credibility. It also damages the credibility of the modular concept overall. We can think outside of the box, and have even made round pegs fit into square holes (see this corner post project) but, modular is not always the best solution.

However, in the majority of construction projects, at the low and mid-rise level we are the solution. This is especially true if you are looking to cut costs regarding the use of a temporary elevator during the construction phase.

In other words, if moving men, tools and some materials is needed on building site, that role could be filled by the modular elevator quite easily and at minimal additional costs.

So, when you start looking at your construction schedule and logistics think about the elevator first. This is not an earthshattering thought. It is common practice for the hoistway or hoistways to be the first item on the drawing board along with stairs. But, here’s the change… don’t think just hoistway. Think fully installed elevator.

MEM elevators are the hoistways and fully installed elevator. They are a steel shaft wrapped in drywall for fire protection with a complete elevator already inside. The elevator car, rails, wiring, doors and frames are in place when it arrives at the site. In the example video below, that is what you are seeing; a fully installed elevator being set in a building.

Most projects require about 4 hours to get the elevator craned into place.

Then the start up can begin once there is electricity at the building site. Because everything is generally already installed, it takes about a week to get the elevator running. With the inspection, and following the appropriate rules for a construction elevator the modular unit can be used during the building phase.

To make the above possible keep this in mind regarding modular elevators:

Modular elevators (especially from MEM) can help you on the jobsite as both a construction elevator and passenger elevator. It can replace the cost of a construction elevator or it can bring a construction elevator to a job where one was not considered due to cost. It maybe time to consider the benefits of a modular elevator as your construction elevator solution. Click the button below below for a Fast Track quote and to get the process started.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.