Affordable Housing – Modular Elevator Solution. No one can deny right now there is a problem for urban areas of all sizes and that is affordable housing. According to the most recent stats from “The State of Homelessness in America” a publication of the Council of Economic Advisors, a half-million Americans struggle with housing. 65% of that half-million can be found in homeless shelters while an astonishing 35% or nearly 200,000 are on the streets.

But, I really didn’t need to give you the stats. A stroll down the street in many of our cities reveals the problem without reading a detailed report. Homelessness abounds.

At its core the issue is one of supply and demand. Simply put, there just are not enough residences for a myriad of reasons. As a result the law of supply and demand dictate that many of the homeless are so, because they are priced out of the market. There are just too few housing options. The supply is low – the demand is high and that makes prices likewise high.

One solution is to reform the laws and codes in local jurisdictions that have helped create the problem. Unsurprisingly, the report lays blame at that door and maybe deservedly so. But, good luck with sweeping legislative change, let alone sweeping change fast.

The current political climate in most urban areas makes wholesale changing of housing laws for the better a pipe dream. With that reality it makes the only other solution increasing the supply of affordable housing. The alternative is turning a blind-eye to the problem or to burry our collective heads in the sand.

If more units are the best solution a couple of hurdles need to be crossed. Both time and space need addressing. I am not taking about Albert Einstein and the theory of relativity. Where (space) the housing units can be placed and how fast (time) they can be erected is the concern. This is an immediate crisis and one that will not go away without action so, the faster new housing can be readied for occupancy, the better.

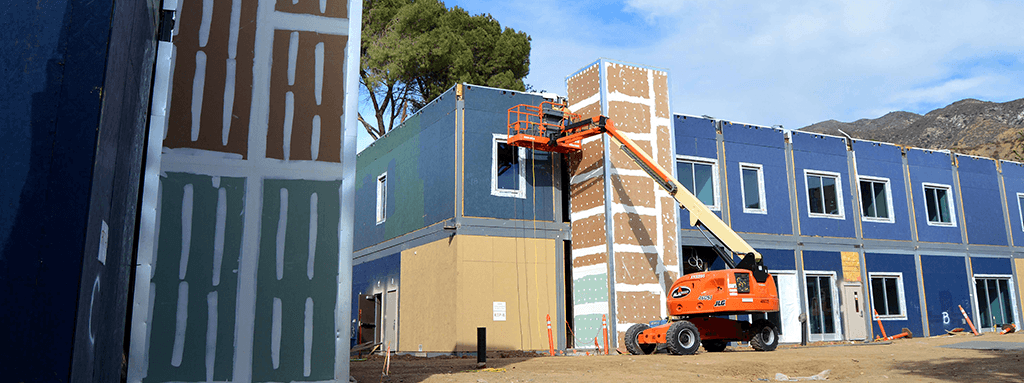

When it comes to housing where it is placed is always key. I recently toured neighborhoods where two completed affordable housing units where ready for occupancy. During the tour I noticed that surrounding the new modular buildings were rows of houses and small apartment complexes. They lined the street, crammed closely together. The houses were probably built in the 40’s or 50’s and most of the houses were still occupied. Several showed a high level of pride in home ownership. As a result it would be unrealistic to acquire those properties in bulk to create a new, sprawling complex. It would be costly and inefficient.

I did however, notice two or three dilapidated units, usually grouped in clusters. There were no rose bushes or neatly trimmed lawns. Graffiti was more common than a car in the drive. They were obviously abandoned. So more housing could be more easily accomplished to use those small narrow lots, instead of buying and bulldozing dozens. But, solving this problem takes more than just a new house being built in place of the old. Multiple units would have to go in that space. That means building up. In the two units I toured it meant a modular elevator.

The second you say “elevator” in any project that is time sensitive eyes roll. Everyone knows that traditional, old-fashioned elevator installation wrecks the timeline for completion. Tacking an additional 6-months, a year or more to the completion date is not unheard of. So, building an affordable housing unit with a traditional elevator is not addressing the immediate need at all. It certainly doesn’t show the homeless population much compassion for the plight they are in, especially when there are alternatives.

Modular building is a much faster option. In the two examples I visited both were purely modular. However, a modular elevator can be used in any type or building project. Even retrofit applications can have a modular elevator installed.

The time savings is because the elevator being built as a completed unit in the factory while the project is still in the process of site prep and permitting. They are then delivered to the jobsite as finished elevators.

Modular elevator units from Modular Elevator Manufacturing can even be used as a construction elevator as they are delivered when you want them.

The elevator is placed in less than four hours and when power is provided they are started up in less than a week. The elevator is removed from the critical path. Problem solved.

Time and space has been inextricably combined by Albert Einstein. His theory linked both into one entity. The same is true with the housing crisis we face.

Time and space are huge obstacles that are linked in the quest for affordable housing. Modular elevators are the solution to addressing both problems at once. The space available means to address the housing crisis we are forced to build up in multi-story units. However, concerns over time constraints and the need to act quickly have dampened the enthusiasm for a multi-story solution. Modular elevators put that solution back on the table. It has worked successfully already in a number of projects we have been a part of.

We are ready to discuss a vertical transportation solution for any low or mid-rise project. Hopefully, we can be a part alleviating the issue of homelessness. Affordable housing is an immediate need and we can be part of the solution. To get the process started just click on the button below. We can provide you with a quote in less than a day.

At Modular Elevator Manufacturing we are fond of saying you get the elevator delivered when you want it. But, exactly how does that work? Obviously, you can’t decide on Friday you want an elevator and one pops up on Monday.

There is a process, however it is not laborious and in comparison to stick-built options. It is significantly easier. But, still there are things that must be done in a certain order for you to get a fully installed, commercial quality elevator set on the day you want.

First, a quick explanation as to how modular saves time and helps you with your project. This will help you see the need for the steps we have put into place. With modular construction overall the key is the period between a project being greenlit and the site prep and foundation work being completed. During that time in traditional construction there is some activity, but most of the work is in a holding pattern.

With modular all of the various components are being built during this time period. So when the cement is dry, the crane arrives and the project get’s its elevator and other modular units if any. Not to confuse matters, but it really doesn’t matter to us when you want the elevator at all. In some projects it goes in first, in others last, some in stages. It all comes down to when it is best for you as long as nothing impedes the crane putting it in place.

So now we get to our process. How does it work for your benefit by taking the elevator off the critical path. I hate to be repetitive but, just to remind you it is a fully installed elevator being delivered (car, rails, wiring, doors, etc. all inside the hoistway). In most cases it will be set in 4 hours or less and then started up when there is power. It has to be adjusted, but all that takes less than a week in most cases. Many people still don’t believe it when the unit arrives on time and completely installed. They are use to the old-fashioned way elevators are cobbled together where deadlines are more like guesses.

There are ten general steps from requesting a Fast Track Number to a fully functioning elevator. Some of the steps literally takes place overnight (like getting you a Fast Track Number). Other steps like the design phase takes a bit longer. We can expedite some of the process as well and there are things you can do to move things along. We will get to that, but first below are the standard steps.

You will notice that it takes 16 weeks to produce a high-quality product. That can be shortened, but not significantly. We produce high-quality elevators and are not a company that will rush things and put the riders at risk. Likewise, we will never compromise on safety on the construction site. Some promise an 8 week elevator, well that can cause disaster.

So to shorten the process the most important thing you can do is to get “Step 3” completed as fast as possible and provide us with a general date you would like to have to the elevator delivered. Completing “Step 3” ensures that the engineering and design will begin and providing a prospective date will allow us to plan and block out manufacturing time for you.

Another thing you can do to keep the timeline short and moving forward is being responsive to requests. Sometimes a project can be delayed for a week or more while we wait for a simple signature.

Lastly, make sure your accounting department knows the process. Sometimes internal processes can slow things down.

Remember, our goal is to get you a fully installed elevator when you want it; not too soon or too late. Communication is crucial. We will be proactive in contact with updates. Also, we understand when the delivery date changes. It is the construction business so things happen and pushing out is a reality. We will remain flexible.

To help stay flexible and informed, your primary contact will be the same person through out the entire process. The person that supplied you with the Fast Track Number will be the same person managing the project every step of the way. They are knowledgeable experts in the industry!

Because we have the most experience in the modular elevator world, we can smooth out and anticipate any problems or issues before they occur. This leads to success of your project as a whole and the elevator portion of the building. We consistently accomplish our goal for our clients of an elevator delivered they want it. We want to do the same for you. Let’s get started with a Fast Track Quote today. Click the button below.

The year 2020 has been a well-deserved punching bag. With the Covid pandemic, governmental mismanagement, the US election, forest fires from California to Australia, riots in American cities, airline crashes, earthquakes, tornados, volcanos, floods and even locust, it will go down as one of the worst years ever in many people’s minds. With bad things occurring in almost biblical proportions how can I blog 2020 Good News?

First, let me say I am purely looking at this from an economic perspective because without a doubt it has been a horrible year for many that have suffered with Covid or have lost loved ones.

And even sticking with just the economics let me acknowledge that for many 2020 has been a devastating mess. Especially in any small to medium sized business that thrives on in-person contact. Masks just don’t work when you are trying to eat out. Then you have all the rule changes about who can go where and do what. I am horrified to think about what the owners and employees of those businesses have been through. Beyond that, what happens if this drags on much longer? We will become a nation of chain restaurants and superstores with jobs permanently lost. The current shuttered stores will just disappear and mom and pop will simply have their hopes and dreams dashed.

However, in the macro 2020 becomes good when you look at humanities collective ability to thrive despite challenging times. Applications for business licenses are up surprising. We are a resilient bunch.

It is also good news if you are in very specific markets. Some have shown surprising growth despite all the bad news of the past twelve months. Who amongst us would not like to turn back the hands of time and buy stock in Netflix, Zoom, Dominoes Pizza or any number of pharmaceutical companies. They are unapologetic winners. This past year has not been bad for many with often the opposite being true.

Modular Elevator Manufacturing thankfully falls into the category of 2020 winners despite the challenges. It begins with the fact that most building and manufacturing was considered essential when others were forced to shutdown. And then generally the entire modular industry is on a continued, decades long upswing. As stated in the recent 2020 Smart Market Report for Prefabrication and Modular Construction by Dodge Data and Analytics:

Prefabrication and modular construction are both experiencing a significant expansion of interest and use as the construction industry seeks to improve safety, productivity, quality, cost, schedule and sustainability performances while continuing to face workforce shortages, cost uncertainties and other challenges.

Stephen A. Jones – Senior Director Industry Insights Research/Dodge Date and Analytics

We at MEM can anecdotally confirm the data put forth by the experts. There was a “significant expansion of interest and use”. In the year 2020 Modular Elevator Manufacturing doubled (yes doubled) sales and production. Vice President of Sales and Marketing, Hugo Beltran is proud of the accomplishment. He said, “The 2020 results are astounding and as a result we’ve had to double the factory space and output capacity. And amazingly we are projecting another doubling for 2021 based on projects already in our pipeline.” 2020 good news!

Although, Beltran would like to take credit for all the growth, he recognizes there is more at play. His team was crucial to success, but there was more. He said, “The construction industry is looking for real solutions to real problems.” And “There are economic and market fundamentals assisting us as the modular industry addresses those problems. So hard work by the MEM employees and the needs of the construction sector are pushing us forward in hitting all-time highs.”

Those needs as echoed in the Dodge report are: cost predictability, improved quality, improved safety, increased schedule certainty, and reduced waste. MEM is simply taking advantage of the opportunity by providing real solutions to longstanding problems in construction. But meeting needs must be more than marketing gimmicks or props in a storefront window or the growth will not accompany the construction market move to modular solutions.

That is why in the modular elevator segment, some flourish and prosper like MEM, while others struggle. While some have to explain away shoddy work and poor engineering. MEM demonstrates what decades of experience can provide with superior service, workmanship and engineering. It is why some struggle with growth despite a market that is booming. While at the same time MEM discusses a Midwestern facility to meet national sales demand. MEM can say 2020 good news (at least in some respects), others are just glad to see it go.

Hopefully for all 2021 will mean a return to more prosperous times and not just some segments. But one thing for certain, if predictions are anywhere close to correct and the market continues to embrace modular solutions in construction, MEM will be a leader in the elevator industry with more growth yet to come.

If you want to be a part of the solutions provided by the modular industry we are willing to help. We will answer any of your questions and provide a Fast Track quote. If you have a low or mid-rise project just contact us. Click the button below and fill out the information. A quote will be prepared and sent to you within 24 hours.

At Modular Elevator Manufacturing we want to thank you on this Thanksgiving Day!

This has been a tough year in a number of ways, however we have continued to grow and expand. We realize that our growth comes from a dedicated team of professionals that manufacture, install and sell our elevators. Thank you to all the employees!

But, just as importantly we want to take this time of Thanksgiving and show our appreciation and heart felt thanks to our loyal partners.

We give thanks that together we make MEM a wonderful solution and a wonderful company.

Thank you!

Easy cab construction makes quality MEM elevators possible. With old-fashioned traditional elevators, the cab is built like a ship in a bottle. In a dark, cramped hoistway one piece of the cab at a time is hand carried into the shaft. It is then assembled. This can lead to significant issues. Fit and cab quality suffer, not to mention all the on-site storage required and the increased possibility injuries. This old method makes very little sense.

The example photo below shows a better way. You can see four elevator cabs in the assembly process. There is plenty of light and plenty of room. We use jigs and templates to make sure that the fit is perfect and overhead cranes are used for any heavy parts. Also, our experienced and approved technicians and inspectors have access all the way around the cab. This means higher quality.

With the task of assembling the cab moved to the factory floor, your job-site remains clutter free of materials, tools and packaging associated with the elevator. Because of that, tripping hazards are removed making a your work area safer. And work is not held up in the site areas normally set aside for storage of all the crates of elevator parts and tools.

As you can see in the photo above whether you need one, a dozen or more low and mid-rise elevators, we can have the elevator cabs ready to be inserted in our factory. The elevators and hoistways can be mass produced for replicated design/build projects spaced months, or even years apart. Additionally, banked or duplexed elevators are a snap to deliver. We can also produce multiple elevators for larger projects. It is easy for us in the factory setting to complete the elevator or elevators you need and have them shipped for placement.

How do we make it so easy? The process begins with placing an order, approval of drawings and then factory production begins based upon when you want the elevator delivered. The elevator fits your time schedule. This is a big change from the old way elevator were built on-site where the elevator company controlled your process and timeline.

Once scheduled we simultaneously build the hoistway and the elevator cab on two separate tracks. At the end of the assembly process the cab is inserted. Then final wiring, inspection and testing is completed, it is shrink- wrapped and loaded on a flatbed truck for delivery. It really is that easy.

We have more experience than any other modular elevator producer manufacturing over 400 elevators and have dozens of years experience in the trades. Our elevators are as easy as one, two, three.

Finally, if our system seems to make more sense than the way elevators are currently installed, contact us for a Fast Track budget number by clicking the button below. You will learn how MEM is the best elevator for any low or mid-rise job. Quality elevators taking you to a higher level.

MEM Parking Garage Solution – Do you prefer aspirin? Tylenol? Advil? A caustic combination of all three? Imagine if you could avoid your headache as an architect or general contractor by not having to worry about the elevator in your project. That solution to your headache is available. And that solution can mean less materials, more parking space and fewer trades to coordinate. Imagine the stress and pressure relief when the elevator unit arrives when you want, fully installed! It is set in a total of four hours and totally off the critical path. It is not a dream.

Placed in hours you can have a Modular Elevator Manufacturing high-quality commercial elevator delivered to your site. All that is left for you to do is the exterior of the hoistway in any construction material you want. See the project below. It is a five-stop parking garage elevator, delivered complete. The durable commercial quality stainless-steel elevator car, was already inside. All the wiring – done, and doors, rails and even the pit ladder precision placed in the factory and it took less than four hours to set.

And this particular elevator came in two sections due to the total travel height. A crane placed the first section. The second followed right behind, easily bolted on top. They match perfectly as the manufacturing process assures the two sections will line up exactly right every time.

The hoistway is perfect, made with steel in a factory. There is no bowing, heaving or contracting like hoistways constructed of block or concrete. It also means that the rails are perfectly aligned. That produces the smooth quality ride you and your customers deserve.

MEM has the perfect solution for your parking garage project. That is especially true if you have designs or plans for several parking garages. Just spec us in and save time and money. Similarly, we can provide elevators for the entire project with solutions for any low or mid-rise application. So before another trip to the medicine cabinet, we’ve got you covered, whether the elevator is placed on the interior or exterior of any building, new or retrofit construction.

We have placed over 400 elevators and have over 20 years experience in making elevators as easy as one, two, three.

Finally, for your parking garage solution and a Fast Track budget number just click the button below. You will learn how MEM is the best elevator for any low or mid-rise project. Quality elevators taking you to a higher level.

Elevator at Sunrise. Pride can be a negative. It can blind you to reality as you puff yourself up. But, on the other hand it is uplifting to see the hard work by so many at Modular Elevator Manufacturing pictured this morning in all its glory. When this was taken…there was pride in the product, the concept, the design and those that provide the best possible option for all low and mid-rise application. Maybe corny, but true. Goosebumps you bet!

Thank you MEM team! Everyday you prove you are the best. Modular Elevator Manufacturing – quality elevators taking you to a higher level.

If you want your own elevator at sunrise experience and a cost and time saving picture like this on your next project click below and get started. We promise to respond quickly with a Fast Track budget number. Keep in mind that the budget number includes the hoistway that is dropped into place. Many folks forget that the elevator comes preinstalled inside the actual steel hoistway wrapped in a mold resistant and fire resistant drywall.

Also remember that the entire elevator and all of the components are already inside. That is why the set process in the picture takes a couple hours and the startup only takes a couple of days. It really is the best system for low and mid-rise applications.

Depending on the application an elevator cab may need to be extremely durable in the way it is made. It may also need to be outfitted with fixtures and a design that will impede or reduce possibilities of vandalism. Lastly, surveillance of the elevator cab is often a necessity as a warning against inappropriate behavior and as a way to visually see what is going down while the elevator is going up. MEM has a solution for all three circumstances.

First, regarding durability MEM cabs are made of strong 14g Galvaneal walls and the platform is 12g. Galvaneal is the preferred material for professional construction and commercial quality elevators for good reason. Its strength to weight ratio is vastly better than other materials including particle board. You may not think that the material used for the cab matters much because they can appear to be the same…until you have a mold problem or a broken pipe that leads to a waterfall into the elevator hoistway. One real life example of how going cheap on the cab can hurt your building project was demonstrated when a construction worker left the elevator door open and exposed one night on a competitor’s cheap wood core model and it rained.

The simple accident led to delays and hundreds of dollar of repairs. Even the interior panels swelled and warped beyond use. This is because particle board (no matter what acronym they use to describe it) is a wood substitute made from sawdust or wood chips and glue. When particleboard gets wet, it can swell or even disintegrate. That is not what you want to hear about your elevator cab.

Also, if sustainable construction is your goal, steel is a much better alternative. During the construction of your cab if particle board is used there is scrap and lots of it. That scrap contains certain chemicals that can be hazardous if not handled properly. This makes recycling difficult and some jurisdiction do not accept it at all as a recyclable material because it can contaminate other wood products. The problem is the use of urea formaldehyde in the glue, a primary component of particle board. It is a toxic substance that can be released during sanding or cutting. Good to know if you have to replace sections that get wet in your cab. Formaldehyde can cause eye and lung irritation, so respirators and safety goggles are required equipment when cutting or sanding.

If a particle board cab is the offer from another company, lookout! It may not be a true commercial-quality product. This warning is especially true in humid areas of the country or when the product is not in a climate controlled situation.

Second, MEM elevators can be equipped with fixtures and buttons that are tough, but still meet all required standards. They can also be produced with an interior finish that reduces the impact of vandalism. Elevator buttons get a lot of abuse, but some high-traffic areas get more than others. Parking garages, some schools and apartment complexes and more remote locations often face an onslaught of abuse. So, depending on your needs and location we can provide solutions to help.

This does not mean that the fixtures are not stylish or don’t meet the design requirements for any job you have in mind. They can be in square or round buttons in the cab or hall call and be in a multitude of colors and finishes.

Depending on traffic and use, diamond plate flooring may be needed and a random grind pattern design will help hide minor scratches and make cleaning up vandalism easier and faster. It is important to remember that vandalism is excluded in elevator maintenance contracts, so a little prevention can go a long way to reducing operating costs.

Lastly, We are not a security camera company, however we work with them all of the time. That means MEM elevators can be produced in the factory that can accommodate video surveillance equipment and systems. This helps you avoid the cost and headache of additional construction surrounding surveillance equipment. Cameras are a deterrent according to a leading elevator publication, Elevator World so if vandalism is a concern, it would be a good idea to work with an elevator company that has experience in security, integrity and a factory setting to help accommodate placement.

Ultimately this all means that MEM can meet your needs for true, high-quality elevators designed well with your needs in mind and fantastic looking elevator interiors that are extremely durable and will help deter vandalism. If you have a parking garage project or elevator in a high traffic area that may need a tough alternative just click the button below and let us walk you through our process and get you started today. You will soon see why MEM is the best elevator for any job between two and seven stories. Quality elevators taking you to a higher level.

MEM Growth – Modular Elevator Manufacturing (MEM) is now distributing their high-quality modular elevators nationwide and as a result have doubled their factory floor space.

As the demand for a high-quality modular elevators has increased MEM is ready to meet that demand with a nationwide roll out of their products. Whether for schools, commercial space, hospitality, medical facilities, multi-family units or parking structures MEM can now meet the demand from the east coast to the west coast.

The key to the increased growth of MEM and new distribution effort is their desire to provide high-quality modular elevators as an alternative to traditionally build elevators. MEM President – Tom Shield is proud of the accomplishment and business milestone, “After 40 years in the construction business and over 20 years in the elevator manufacturing industry, it was time to allow our product to be sold and installed nationwide. We have a great team that knows elevators inside out and the consistent quality we provide has made this growth possible.”

He went on to say, “It is my philosophy that good business is quality business. We do everything that we can to mitigate drama, and low quality and high drama go hand in hand. As an example of safety our EMR rating is .75, which is excellent.”

Because of the continued, steady growth MEM has acquired additional manufacturing space. The factory floor now has twice the capacity of the already successful business. The expansion allows for improvements in the manufacturing process and allows the placement of more jobs inline for completion. It is a huge expansion that MEM is ready for according to Shield, “If you are looking for a better elevator alternative and would like to consider a high-quality modular unit for mid and low-rise projects; we are ready. Our team will answer any questions and provide a Fast Track budget number in hours or over the phone if you call in. We are excited about the new factory floor space and the growth to nationwide distribution.”

The modular concept for elevators is revolutionary and MEM is one of the pioneers that saw the need for safety, quality and fast set and start up. To summarize the difference between modular and stick-built you should know that they are simply conventional elevators, just unconventionally delivered and installed. Modular elevators are the hoistway, built with tough 4X4 inch HHS (Hollow Structural Steel), wrapped in mold resistant drywall to your specification with all the elevator components already inside. That means when they arrive at the site the wiring, cab, rails and other components are already inside the structure. It is then placed with a crane at the job-site in the elevator pit in less than a day and then can be started up in less than a week. This means that it takes the elevator off the critical path saving time, headaches and hassles.

Modular elevators are also extremely flexible in use and can be included in retrofit projects, modular projects or new traditional construction. Generally any time you would use a conventional elevator, a modular can be used in its place.

Lastly, when it comes to design, MEM elevators inside the cab and on the exterior of the hoistway can carry any look or feel. Architects are impressed with their flexibility. If you would like a budget number and be a part of MEM growth on a project you currently are considering, click the button below to get the process started.

Best Mid Rise Elevator Option. Sometimes when people hear about modular and modular elevators, they think that a high quality product is not possible. Nothing could be further from the truth.

With Modular Elevator Manufacturing you always get quality regardless of the type of structure and the amount of use. MEM elevators can be placed inside or outside any type of structure. Even high traffic areas are easy for MEM. The quality is built in from the 4×4 inch tube steel to non-proprietary, industry approved and tested components. These are high-quality commercial passenger elevators.

Just as important you don’t lose control of the jobsite. The elevator in installed in a factory and then set in place on the site when you want it delivered. Once it is set, it is then set up when power is available.

This is a new and better way to install an elevator. Faster, safer, greener and more cost effective.

MEM elevators install quickly. That will allow you to control the elevator part of your building project. It also take the elevator off the critical path. For all the above reasons, MEM is the best mid rise and low rise elevator on the market today.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.