Non-proprietary parts matter. However, often times non-proprietary parts are over looked, not considered or just not understood. So, let’s start from the beginning. What’s the definition of non-proprietary elevator parts and how can they solve problems regarding your elevator choice.

Generally, proprietary elevator parts are components produced, marketed and controlled under exclusive legal rights of the manufacturer. The manufacturer has no obligation to share any information about the part or component, how it functions, how it operates, how it can be repaired or used to adjust or improve the overall functioning of an elevator unless it is contractually obligated to do so.

Non-proprietary on the other hand, means there are no restrictions to the use or what company can repair or improve the functionality of the elevator.

Well that was a mouthful. The definition can be reduced to a more simple, proprietary elevator parts are ones that only the manufacturer can repair or use in a repair or maintenance of an elevator. Non-proprietary opens the door to any qualified and licensed elevator professional.

An even more concise characterization is, proprietary bad; non-proprietary good.

But why? Why are proprietary parts to be avoided when looking at elevator purchases.

There are limited arguments against choosing an elevator that has non-proprietary parts over proprietary. When non-proprietary options were first available, there was a short time that they were considered inferior due to their recent emergence.

That thinking is no longer a concern. There is a decades long track record now that shows reliability and durability for non-proprietary components. Keep in mind that all elevator components and elevator operations are subject to elevator codes, inspections, and parts must pass rigorous testing before they would ever be allowed in an elevator.

Also, much of the functionality that proprietary elevators could boast of is now available with non-proprietary units.

Too many times we receive calls from individuals that are dissatisfied with their current maintenance supplier. They are sometimes unresponsive, operate at their own pace with little concern for the end user or the building owner and often lack availability of parts or tools with many on back order. With proprietary parts you lose the ability to find solutions to the problems you are facing.

This was illustrated in a recent article regarding elevator repair delays. A lack of parts was the cause for denying people mobility and access. You can help shorten that time of repair if you chose for your next project an elevator without proprietary parts. If you want to know more about us, just click one of the buttons below. We would love to talk to you about your next elevator project.

You should care – Elevator parts are not all equal…but they are. Years ago there used to be a commercial that had the catch phrase “Parts is parts”. They were talking about chicken nuggets and not vertical transportation and their facetious point was parts are not all equal. There are better and worse pieces of the chicken to use in the production of a nugget.

In the home or commercial elevator industry that knife cuts both ways and a bit hard to explain. First, it is true there are differences company to company in components. But second, those differences are superficial at best and for a purpose. So the parts are not all equal but… still equal??? How does that work?

That doesn’t seem to make sense so let me explain this weird dichotomy by stating the following. Factually, most companies purchase the bulk of their components from the same group of independent companies. As a result an elevator, home or commercial, is filled with dozens of components and pieces that come from those various companies from around the world. The difference is largely relegated to different nameplates and logos being etched or painted on the components themselves and that is about it.

This gives the illusion that they are all coming from the elevator company you are buying from. Generally that is not true. As a result when you step into an elevator car most often very little of what you see or that makes it go up and down, comes from the name on the control panel. And in all likelihood the bulk of those parts are found in every other elevator you ride regardless of the company.

Also, the vertical transportation industry, for good reason, is highly regulated. Elevators in the United States make 18 billion passenger trips per year according to the National Elevator Industry Inc. For that reason alone it is very important that all parts must meet high standards. You just can’t put anything you want in the elevator as a component. They must be test and approved for quality and durability.

Alright, if only a handful of companies produce most of elevator components and all parts meet the same rigorous standards, how can they possibly be different? Well before I get to that I want you to know that I am not wearing a tinfoil hat. I believe that we did go to the moon, Elvis is dead and aliens had no part in building the pyramids. So what I am about to say is not a crazy conspiracy.

Here, goes. The big commercial elevator companies make the bulk of their profits in maintenance and not selling you an elevator. Shocked? They realized pretty early on that if any certified elevator contractor could provide maintenance, they could lose customers and money. People would simply shop around and find the lowest price for service.

The solution was two-fold. First, sell elevators that require the most expensive maintenance agreements regardless of the purpose. Second, place in those elevators components from manufacturers that will require special tools, passwords or programs to maintain the elevator.

If you combine those two principles with a confiscatory maintenance agreement you have a lock on maintenance income for that unit for decades. And there is really no way for the building owner to extricate themselves from the long-term costs.

So, despite elevator components largely being the same, parts are not all equal. This is by design and for a specific purpose that has nothing to do with the elevator ride or functionality.

Unfortunately, when asked, “What can I do?” the responses are limited. This is especially if you already have an elevator in place. It is not practical nor cost effective to replace the proprietary parts that force you into the long-term contract. It’s like the old adage, you pay for some mistakes forever. But learning from those mistakes is important as well as spread the word that you can make upfront decisions next time that will save you from the headaches and costs associated with choosing the wrong company.

The word to commit to memory is non-proprietary. Non-proprietary parts and components are simply those that any elevator technician can work on. They are not better or worse they are just accessible for maintenance from any company. You can even use the big elevator companies if you wish. It just opens the door to anyone to repair or maintain the elevator. So always, always, always have an elevator installed with non-proprietary parts.

Finally if you have any questions regarding what proprietary parts and components can mean to your elevator project please contact us. At TL Shield and MEM we pride ourselves on giving honest answers to your questions about elevators, home or commercial.

All you have to do is click one of the buttons below to get started.

When we say safe, quality Modular Elevators it is not just empty words or a marketing ploy. We really mean it and we wished that everyone would take it as seriously as we do. Like you, there are rumors from the past of a project with a different company where, while the elevator was hovering over the building, an elevator jack literally fell out and plummeted into the pit. It could have killed someone.

The story is shocking and absolutely true. People were in danger. Beyond that when a company puts out a product so poorly built it not only potential can harm people on the job-site it can also harm the modular elevator industry and the modular industry as a whole. A safe quality modular elevator is always our goal and we accomplish that goal. But, we all suffer the black-eye, when quality is not just suspect, but dangerous. MEM is different and here’s how.

To start with MEM has just been at it longer. We didn’t just pop up out of no where with no construction or elevator experience. We have over 40 years in the building industry and a 20 year manufacturing track record of success and safety. We have never – never had anything like the scare of a 300 pound jack falling from the sky. Our installs go in smoothly because we have so much more experience.

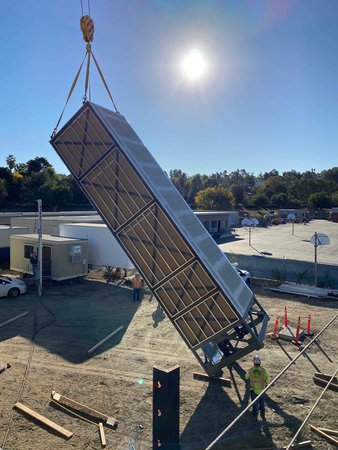

MEM elevators are also engineered with safety in mind. Usually when you say safety and elevators you are talking about for the riding public and our elevators are very safe, never putting the general public at risk. But we have engineered our products so they are also safe to install as well. Part of the many pluses of the modular industry is that it means safety on the job-site. The heavy lifting and working in cramped quarters is moved to the factory with plenty of cranes and space on the factory floor. Plus there is no working at heights while the shaft is being built like in traditional construction.

With MEM we understand how important work site safety is and engineer that into each and every elevator we produce. It may take more effort, higher-grade materials and more care when building them, but MEM elevators are built for safety before, during and after the set and start up.

Lastly, we check every product we manufacture assuring safe, quality modular elevators with our one-of-a-kind 10 Point Inspection by a certified elevator technician. Before the elevator is loaded on the truck, we make sure of the following:

Each of the above is a part of a process that produces consistent quality. If you are not careful you could pick the wrong modular company (the one where the jack fell out). Keep in mind that it is important that it is a certified elevator technician doing the checking and not just any old employee. We have multiple employees that are qualified and capable of checking everything out. We simply cannot vouch for what others are doing, but rest assured we do our best to make sure the elevator you get is the highest quality.

Lastly, we want to assure everyone that modular is the safest and best way to build. It is tested. tried and true and takes advantage of the latest building principles. Whether you are considering the method for an entire building or wanting to retrofit an existing structure with a safe, fast installing modular elevator, reputable companies in the modular building industry are ready to build faster, greener and most importantly safer.

If you are curious about safe, quality modular elevators and have a project in mind that you would like a quote for, click the button below. If you want to know more details about the accident that has caused such a stir, contact me at your convenience. I am always more than happy to explain why modular is the best solution and MEM is always quality elevators taking you to a higher level.

Modular Elevator Innovation – There are a few inventions that become moments in history that change everything. The Wright brother’s first flight, Guttenberg’s printing press and Edison’s light bulb are at the top of the list. But one moment rarely considered is the time Elias Otis cut a rope on a suspended the elevator at the 1853 World’s Fair. On that fateful day when the cable was severed the elevator did not fall due to his unique braking system. The elevator became safe and the world was able to build up creating skyscrapers and a new city lifestyle beyond four-stories.

However, since that great leap ahead, the elevator has remained largely stagnant in how it is installed in a building.

Designers, architects and engineers have been trapped into placing a tower in the midst of the project and after nearly everything is finished, the project is turned over to the elevator mechanic. They come and go as they will and one piece at a time the elevator is built from scratch from crates of parts inside the hoistway.

That laborious, inefficient process is carried out anytime a multi-story project is built. This slows completion, wastes resources and can greatly expand the time that it takes to allow occupancy. But this building mess can be cleaned up through the use of a modular elevator. The modular elevator innovation changes everything.

This innovation is not new. After the passage of the Americans with Disability Act a group got together and thought through the conundrum of providing vertical transportation quickly at a cost that would allow more access. Their idea included building a steel hoistway that could be placed in hours with all of the elevator components already installed inside. The concept was perfect, but execution was lacking.

From an elevator installer’s perspective significant improvements could be made to reduce time, increase quality and diminishing inefficiencies even more. T.L Shield and Associates president, Tom Shield took up the challenge and the birth of the first true and practical modular elevator was developed. Modular Elevator Manufacturing (MEM) was founded and mass factory production of the MEM Elevator System began. Tom Shield said about the process, “We never set out to create an elevator revolution, we just wanted to solve problems to vertical transportation for builders and installers. We feel we have accomplished that goal.”

“We never set out to create an elevator revolution, we just wanted to solve problems…”

Tom Shield – MEM President

As the market expanded additional innovation has been tested and accepted leading to the high-quality alternative to conventional elevators we have today. Shield said, “It has been a long road to market acceptance, but nationwide people are seeing the modular elevator as a solution to many of their problems and we continue to project significant growth.”

The stead increase in market share continues as architects, designers, project managers and building owners see the value in controlling their projects, cutting general construction costs and having occupancy faster than with old-fashioned traditional elevator installation.

As you can see Modular Elevator Innovation has led to an alternative that has been accepted and should be considered prior to any multilevel project. To reduce time, costs and headaches, we have a solution for your project woes regarding the elevator.

The modular elevator is not just a quick tip up for the outside of a building. It can be banked with other elevators and fitted with any design. Our commercial quality elevators can be used in retrofit or new construction just like traditional elevators, they just don’t come with the same baggage.

So if you would like to explore more, you can schedule a live virtual online tour and see first hand how we produce our modular elevators. You are also welcome to visit us in person as well. Just let us know when you are available.

Lastly, if you have a project in mind and would like to explore your total costs and benefits regarding our modular elevator complete a request for a Fast Track Quote. In about 24 hours, we will provide you with a thumbnail quote and get your project started. Just click one of the links below.

Modular Elevator Footprint – Often times when comparing the revolutionary MEM Modular Elevator System to traditional elevators the modular elevator footprint size comes up as an obstacle. This is especially true regarding interior placement. In this blog post we compare how much space is taken up in an apples to apples comparison.

There is a lot of confusion over exactly how much space the hoistway will ultimately require. To clear this up we went to our valued California partner TLShield for answers.

Senior Sales Executive, Craig Braund is a leader in the elevator and construction industry. He is known for using clear communication to solve problems for a variety of builders and architects. He took the time to examine the statement and question:

A modular elevator footprint takes up more space than a conventional elevator. Fact or fiction?

Coming to a conclusion on this question can be important. Especially to builders, architects and contractors when they consider switching to a modular elevator in the interior of a building. They like the fact that the modular elevator is off the critical path. It also saves time on the job and ultimately is a cost savings. However, switching from a conventional elevator, already designed in the project, to a modular elevator can be a hard decision to make. This is especially true when they are presented with the inside pit dimensions. This is because they believe they will have to totally redesign the building space for the elevator by a foot on each side to fit the MEM Modular Elevator System in.

But below, you can see that isn’t the case.

A typical 3500G (Gurney) conventional elevator has an inside pit / hoistway dimension of 6’-11” x 8’-6”

The MEM Modular Elevator System HW-2 3500G (Gurney) has an inside pit dimension of 7’-10 1/4” x 9’-6″

But is the required building space really larger? Here’s where it gets interesting.

The hoistway walls on a conventional elevator are typically between 7” and 8”. So the actual overall outside dimension (using 7” walls) of the elevator and hoistway is 8’-1” x 9’-8″.

A HW-2 3500G MEM Elevator with a 2-hr fire rating has a overall outside dimension (outside steel plus 2 1/2”) of the elevator and hoistway of 7’-9” x 9’-4 3/4″.

So in reality, an interior MEM Elevator actually takes up less building space. When the hoistway walls are utilized as building walls as done typically. The good news? No major redesign is necessary at all.

Therefore the answer to the “fact or fiction” question is… fiction. The modular elevator footprint is actually smaller.

If you have been holding back on considering the MEM Modular Elevator System because you thought interior placement was a problem with the modular elevator footprint size, we hope you reconsider.

As you can see we are a great option. We can be your solution to taking the elevator off the critical path. Additionally we can provide you with time and cost savings. To explore more you can click the button below. Sign up for a LIVE VIRTUAL TOUR of our facility where we show you how we produce this revolutionary product. If you have a current project and would like to explore more with pricing click the Fast Track Quote button.

We would be glad to have a conversation and help you with a solution to your vertical transportation needs.

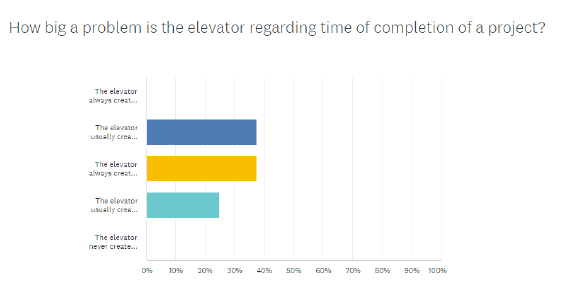

Elevator Poll Opportunity to Change / Oct, 2023 – As most of you know we have been conducting a one of its kind poll. For the first time a poll was sent to the entirety of the construction industry regarding elevators. Architects, general contractors, engineers, design build firms and elevator professionals responded. Additionally, to have more clarity and to focus our efforts on real solutions we held a series of open forums where we discussed the results of the poll. We heard anecdotal stories that confirmed our findings and consistent reports of issues regarding the current traditional elevator industry.

After the poll and subsequent analysis we can say there is an opportunity to make changes for the better in the construction industry.

And that always was the point. The poll confirmed the problems that had always been rumored. Now we can begin a revolution to foment change that is solutions based. So in this article we are going to examine each of the five inferences the poll questions and forums confirmed and make some general suggestions for improvement.

After all, our desire is to improve an industry that has not substantially changed in how it installs elevators or deals with the construction industry for over 150 years. To make improvements we wanted to start with actual information from the people that deal with elevators and have to live with the challenges they present.

And then start the conversation about solutions. This is the beginning of the discussion regarding those solutions. We know where we have been and now we must start charting a path to where we are going in the future.

The polling and results of the open forums are pretty telling. The current way the construction industry and elevator industry function or rather doesn’t function, is a problem. Both sides have points and counterpoints, but change is stuck because solutions are slow to come forward and then equally slow to be embraced. The poll reflected this with a well documented reticence to adopt each other’s, other options.

We are not hiding the results because we want a full discussion of experiences that back up or reject the results and other inferences from the data we missed. The bottom line takeaway; there’s a problem. So much so that some are grasping for solutions. But don’t take our word for it. We encourage you to look at the graphics and add your comments below as to what your impressions are or the inferences you draw.

This is the beginning of thinking through the issues and not the final word. Just a discussion of possible solutions. This is a continuing of the dialog. We look forward to your input and feel communicating with continued analysis will help both industries (construction and elevator).

With that said, here are early inferences drawn from the poll and open forums:

The overall customer experience is negative regarding the elevator industry. Over 88% feel the experience was horrible to needs improvement. Over 40% felt it was horrible to barely tolerable. No sugar coating it, it is not a good result. However, keep in mind this attitude shifts dramatically depending on occupation or role. 90% of design professionals believe their experience to be generally good. Easy to use websites for plans is a big help. Turns out however websites can’t install an elevator. This also means that the elevator industry focuses effort on the sale of elevator units, not difficulties of those downline from the decision.

The results we found are uncomfortable. Keep in mind that this poll was sent to the elevator industry as well, so they know there’s a problem. The elevator industry front loads their efforts to the sale of the elevator and more importantly to the sale of the maintenance plan. That is their model. They know that if they are chosen they get decades of maintenance fees. So what can change the elevator market and its reputation? It is the market itself. Not to push the problem off to the customer, but until alternatives are explored by the buying public, the elevator industry will continue to be the monolithic monopoly it has become. Immediate considerations is to refuse to purchase an elevator with proprietary parts. Proprietary parts are the hook that keeps maintenance forever attached to the sale and handcuffs the buyer to the elevator company.

Also, consider moving the pain of the elevator selection to the front of the process. That is where longer-term issues can be addressed in the contract for the elevator. Once you are into or past the bidding stage it is in all likelihood too late to make a change as the hoistway placement and size has been determined. One solution being used by a frustrated builder discussed in our forum was to make the hoistway opening big enough to accommodate nearly any elevator. He felt it gave him more flexibility to shop and compare. The elevator problem is so great that losing building space was considered to be a reasonable solution.

The better option is prioritizing the elevator purchase before the drawings are complete and always purchase elevators with non-proprietary parts.

Delays are a huge issue. 65% in our poll say the elevator always creates delays. The nature of how conventional elevators are installed is the problem and solutions maybe limited unless you look into alternatives such as modular elevators. The hoistway is built along with foundation and there it sits until power and a controlled environment is secured.

At the end of any build, the pressure is on to finish up. Tensions run high as time is running out. One person we talked with about the frustration said, on a job the elevator company pushed out completion more than 6-months passed the expected occupancy date. Understandably he was apoplectic, but stuck and he knew it.

The traditional elevator industry has no solution for the pace of the install. They will be done when they are done. The timeline for the elevator crew is often times at odds with the construction manager’s expectations. Increased communication can be a big help, but this can’t be just chatter. There must be clear timelines to be adhered to and notification of steps to completion must be communicated clearly to everyone involved. This is especially true regarding life/safety trades and when they are checked off as complete. One phone line can cause delays of weeks and costly change orders.

Explore other options. With modular elevators the elevator arrives already installed and can even be used as the construction hoist. It sets in a couple hours and the start up is a week long process not months. With traditional elevators, back ordered components, over-stretched elevator crews, and even poor weather can stall or even stop installation. When the installation takes place in a factory there are no such delays.

The most important consideration regarding the purchase is on-time start up and use. But there is no control over that with current industry standards. The conventional elevator is an immovable object stuck on the critical path. That creates a feeling of loss of control or helplessness.

Cost, Type of Conveyance and Structure are also concerns that sometimes present few options for improvement.

Regardless of the type of elevator, the inspection process is out of the hands of the elevator contractor in most jurisdictions. These must be scheduled in advance. So the solution is to make sure you have a checklist of completed items, before the inspection is scheduled. Call backs can mean costly change orders and delays.

When it comes to costs that is often linked with conveyance. Watch out for being oversold. It has been relayed to us in any number of conversations that traction or roped units are being recommended for extremely short travel distances. The initial cost for traction units is higher as well as the lifetime costs through maintenance agreements. Quit over buying your needs.

Additionally, cost of the elevator does not encompass all the ancillary aspects of the build, so at the end of the project the actual investment in the elevator is most often not known. How much money per stop is wasted due to call backs of mud and rock crews, flooring installation and painters? One construction professional indicated the traditional elevator costed him $30,000 to $40,000 more per stop due to call backs of other trades. He found another alternative.

If you want the elevator off the critical path a modular elevator is the route to go. The market for modular elevators is expanding with large elevator companies offering alternatives overseas and new companies starting domestically. Modular is the future for low and mid-rise applications.

There is flexibility! No one polled automatically keeps the same elevator company due to past experience. This means change is possible. But it seems the choice is pushed back to the bidding process creating a lack of flexibility and specs makes innovation difficult.

Using your flexibility to make choices early is the best alternative. By the time you get to the bidding process all of the flexibility you once had is gone. You are locked into the same traditional models that you have always used.

The bidding process leads to specs that stifle innovation. As we have learned and discussed in our forums, elevator companies largely ignore the construction specs in any case. So why push the decision out to or past the bid process were you are now under more of the elevator company’s control?

By the time you are passed the bid phase, it is often too late to consider other alternatives without additional costs. All hope of innovation is gone. Ultimately, construction professionals are often locked into just a couple bad choices so leave your options open, it maybe counterintuitive but research and decide early.

Finally – Start up is the elephant in the room. It is a huge issue, but out often out of your control and even out of the control of the elevator installer, especially regarding inspection and final approval. Cost overruns are constant.

One truism confirmed in our conversations is that lack of communication costs time and money on the project. One example was the push by the general contractor to expedite the elevator inspection. It led to the elevator being fully ready but life/safety aspects of the building were still not complete. That meant a failed inspection and then change orders to return for a second inspection. Open communication would have resolved that issue before it became one.

There are options that include a fully functioning elevator installed that can be used as the construction elevator and then converted to a passenger elevator once construction is complete. Knowing it runs and passing inspection as a construction elevator, is a big benefit to final turn over of the unit. It certainly speeds the elevator to complete readiness faster.

This poll and open forums led to a great new starting point for the construction industry to begin to change in how it views elevators and all the pitfalls. It also gives Modular Elevator Manufacturing and others in the elevator industry the perfect opportunity to change the industry from the inside out. We again are asking you to join us in this revolution. That does not mean buying a Modular Elevator Manufacturing System. It means looking at the elevator industry afresh and deciding early on what mode of vertical transportation works best for the project you are on.

We will continue to update and change our recommendations as responses pour in. Based on the response so far, it is evident there is a problem out there and we can begin to fix it together. The industry can change and improve its image, product and installation methods.

Also, by working together we can reduce headaches, improve start up times and cut costs. That will lead to better strategies and decisions when including an elevator in your project. Elevators will never be problem free, but they can be improved upon and that is our hope as we lead an Elevator Revolution.

In the mean time if you want to know more about the MEM Elevator System please let us know by clicking a link below. You can take a virtual tour of our factory where we openly discuss our process and the elevator industry. You can also request a Fast Track Quote if you have a project in mind and are curious about the solutions we offer. One more reminder – please comment below. Your input is important.

Elevator Forum Produces Results. For those of you who are new to Modular Elevator Manufacturing (MEM) we are an elevator manufacturer. But not your typical company. We are trying to foster a revolution in an old industry that has not changed in 150 years. To help in that effort, we have sponsored a poll about the elevator industry so people in the construction industry can let us know the challenges they face when an elevator is part of their project. You can still participate by clicking the button below. It is just five short questions.

We then take those results and further define the issues you face by holding an open forum and clarifying the issues. The next step is then to make an honest effort to reform an industry in desperate need for a revolution. We will make changes to how we do things but also publish important information that you can use across the industry regardless of who you choose for your vertical transportation needs.

One vertical industry at a time we will be offering these opportunities for change. Our first was a success with the parking garage industry. The results of the forum were not surprising, but interesting to say the least.

First, when we said we were having a free and open discussion, we expected people to strain to participate with a largely one-sided conversation. Nothing could be further from the truth. We went through each of the poll questions and listened. To our surprise there was a lot to hear.

For instance when we asked specifically about time of completion and the elevator’s impact we were shocked at the candor.

The elevator installation “Usually creates major delays” to “Usually creates some delays”.

This is a major pain-point for the builder and the elevator industry.

Discussing that single issue propelled a discussion that elevator manufacturers need to hear more about. It seems that the overriding thought from builders across the construction industry is that the elevator installer are actually looking for ways to leave the jobsite. That leaves timetables for completion unpredictable.

It turns out that elevator mechanics once they get on the site are often looking for ways to get back off the site as fast as they can. We know many of the major reasons that occurs. An emergency somewhere else is a good reason if true. But they become more difficult to swallow after that and seem more like excuses. Examples such as it is too hot or too cold in the hoistway or shaft has led to a running joke in the elevator business (especially in colder climates), the technician watches the thermometer more than the time clock. If it drops below 55 degrees, time to go home.

The elevator company will sometimes come clean with an acknowledgement they double booked or they are trying to finish up another job somewhere else.

You will hear that they don’t have all the parts they need.

But a new reason to abandon the jobsite from wayward elevator mechanics came to light as well. I had never heard this one before. It is too dusty in the shaft. That was a new one on me.

Overall, because of a lack of trust in the industry as a whole or lack of trust in an individual company, builders are just not buying it.

This discussion led to the most damning indictment of the whole conversation. The elevator company is just looking for reasons to leave the site and they are not team players.

“The elevator industry generally takes the opinion, too bad.”

The feeling of the group in the forum was that everyone in the construction trade from plumbers to electricians have failings; they double book, they fall short in deadlines and have cost overruns. But after its all said and done they do their best to finish the job on time as promised. The other trades think through the problem or through the difficulty and work with the rest of the team to pull it all together.

That may or may not be an accurate picture, but it is the perception. The elevator industry generally takes the opinion, too bad. That has to stop.

I always hate using football as an analogy, but it fits here. When I was playing I could miss a tackle or a block, miss a read or blow an assignment, but if I did everything I could for the team to be a success it was forgotten (usually after 100 down and ups). It is true that I might have to ride the pine, for a game or miss a first-half, but all was forgiven. I was welcomed back. No one was never endanger of being kick off the team for a mistake.

The elevator industry has a habit of acting like they can do what they want, when they want and there is nothing that can be done. Mistakes are common and often and little effort is made to make them right. If this keeps up they are going to find themselves kicked of the team.

But the time for change is coming. A revolution is starting. It may begin small, but we are hoping to detect the pain-point through the polling and forums and then lead to find solutions. It is going to take honest communication throughout the construction industry from architects to elevator maintenance companies, but change is on the way.

And this leads to the final point where we usually turn all this information into a pitch for our revolutionary product. Yes, you can click the links below for more information if you want, but that is not the purpose.

If you want to be a part of the elevator revolution and improve the way the elevator is placed, designed, started up and maintained we invite you to be a part of the solution. You can start by taking the simple five question poll. It will only take a couple minutes. You can then contact us and ask to be included on future phone conferences. We will discuss the poll in its entirety and you can have a hand in influencing the future of the elevator industry.

If you want more information about the MEM Elevator System just click the link below.

Shark Bite and Modular Elevators – Newhart Middle School/Mission Viejo, CA. Innovation can be hard to accept and try. In Mission Viejo however, they are embracing innovation and teaching it in a brand new facility at Newhart Middle School.

At the recent open house Superintendent Kirsten Vital Brulte said, “We look forward to seeing how they use this innovative space to further their STEAM education.” There is no doubt the facility will be put to good use, but there could be a bigger lesson about innovation and acceptance of technology that we all could learn.

This lesson of trying innovation struck a cord with me during a recent home renovation. We added on to our modest farmhouse a kitchen and upstairs bath. Of course to keep the costs under control, my wife and I decided to do some of the work ourselves. I am not totally without skills. The result is we took over some of the obvious stuff that we knew we could do. Painting, trimming out windows and doors and baseboards.

I also considered making the plumbing a DIY project. It was just a sink and dishwasher in the kitchen. Pretty straight forward. However, I was worried as it had been sometime since I sweated pipes. I then looked into Shark Bite plumbing and my suspicious mind started racing. It looked easy…too easy. If I used the snap together plumbing, I would definitely be able to avoid the difficulties of copper, but at what cost? Was this truly going to snap together so easily and hold?

I would have definitely saved a ton of money, been able to put the plumbing in faster and complete the job on my schedule, meaning the kitchen would be ready sooner. You can only eat take-out off of paper plates for so long.

Ultimately, however, I wasn’t convinced. I just couldn’t do the job with this new fangled product.

We got a great reference for a plumber and so after he saw the plans and agreed, I wrote a check and scheduled the job. Weeks went by but in his own sweet time he arrived. However, as he clambered out of his van, what did I see? Rolls of PEX tubing. Also, all his shelves were filled with connectors and fittings for snap together plumbing. He said that for jobs like mine, that was what everyone is using. It was easy and quality.

I watched agog as he went to work. It was as he promised and I had been a fool. I could have saved money, time and effort by doing it on my own with a more advanced product. Before lunch, he was out the door telling me to call if there were any problems and let him know when everything else was done so he could set the fixtures.

I guess you sometimes just have to live to learn.

I immediately saw parallels between Newhart Middle School, Shark Bite and Modular Elevator Manufacturing. The MEM Elevator System and snap together plumbing have been on the market for over twenty years. Both are innovative and have revolutionized their industries. They are proven to reduce time, reduce costs and are just as good as what they have replaced. High-quality is a must for a commercial elevator.

Lastly in my case regarding plumbing anyway, both struggle with acceptance. Shark Bite and modular elevators have a hurdle to clear. They must convince the market by seeing them in action and by being open and honest about what is offered and the differences between the revolutionary and conventional.

So we are working hard to provide examples of our product, like Newhart Middle School pictured. What you are seeing is a fully installed elevator being placed through a hole that was left in the build. It was set in just a couple hours and was started up in a couple of days. Revolutionary!

As you can see, the project looks great. It went in faster for the school with no disruption to classes and overall their embracing of innovation in what they teach and how they teach it, will be a lesson for all.

If you would like to see about this project or others like it, we are opening up our factory to live, virtual tours at your convenience. All you have to do is click the button and fill out a simple form. We will then schedule the tour at your convenience. During the tour we will answer any and all questions. You can also schedule an in person visit as well.

Lastly, if you have a project in mind and want to speak directly to one of our representatives fill out the Fast Track form. We can provide you a thumbnail number in hours.

For more great photos of the project, visit our good friends at Miller Construction. Their team did a great job!

Place your elevator order now. There are three distinct dynamics currently at play right now at Modular Elevator Manufacturing (MEM). These dynamics may come into play regarding your elevator order. They may influence when you pull the trigger so we want to be up front in all respects.

We are facing challenges just like most of the construction industry with supply issues and inflation. Elevators are unique, but not unique enough to avoid basic economics. So the current climate inevitably leads to the following question. When do you pull the trigger and OK the elevator order? You know you need one…so when do you start the process. Below are some things to consider.

First, we recognize that times are tough or at least getting that way. These tough times extend to all your suppliers us included. As a result we want to let you know everything we can to keep you informed. See, we understand the dilemma you are in and want to be real clear and honest about the market now and how it will effect your building project. So here are three important things to think about regarding timing of the elevator order. Consider the following:

Explaining point one in more detail. There is a myth floating around out there that an elevator can be produced in less than eight weeks. Lead times for the components alone blows that old canard out of the water. It is simply not true and if it would be possible, I’m not sure I’d ride in it. How the process really works in the modular industry is the elevator begins production based on the delivery date.

“We know deliver dates change and you don’t have a crystal ball! But it is crucial to get your project in line early.”

We simply count backwards based on the time it takes to get high-quality parts delivered and for production to occur. That is when we place your elevator in line for production. Yes, some components are produced in our factory, but like discussed in other blog posts, elevator components come from just a handful of companies. So we set the day of production beginning when the parts will arrive and so production finishes when you need the elevator. Simple math allows for you to get your elevator when you need it, not before or after. As our queue is constantly filling and emptying letting us know early by placing your order gives us more flexibility. The earlier we know we are producing your elevator the better. We know deliver dates change and you don’t have a crystal ball! But it is crucial to get your project in line early.

The second point is more difficult on everyone. If you don’t believe me, step outside and look at a gas station sign. The cost of everything delivered has been on a steady rise. Inflation is not “transitory” as first errantly promised and is probably here to stay for the foreseeable future.

The elevator industry has been somewhat shielded from the rise as only around 10,000 elevators are sold in the US every year. It seemed like there may have been enough chips, ropes, and buttons to go around, but supply is tightening.

So far we have done our best to hold the line, but it is becoming more and more difficult to avoid costs being passed on to us from others. That means if you are at a stage of where locking the elevator in is possible…do it now. Of course we would want you to lock in the MEM Modular Elevator System, but it is wise advise regardless.

The last point from above. With all construction costs set to increase, finding savings is crucial. Depending on the job, you may well be able to draw a line through an item completely in your budget. If you use the MEM Elevator for the construction elevator as well we save you money. But, keep in mind the first two points hold regarding timing and inflation. Lock in your elevator order now.

Nothing can be more irritating than facts especially if you don’t like them. But, this blog post laid out the facts about an elevator order and the need to think it through quickly. Because although this is about MEM, it is largely the same throughout the elevator industry (here’s an article). Prices are going to increase.

We can help you with your decision making process by giving you a live virtual tour of our factory where you can ask any question and get clear answers. To sign up click the button below. We can and will discuss any questions you have.

If you do have a project in mind and would like information on pricing, logistics, quality or our process just give us some general information. We will respond back with thumbnail prices and be ready to answer any of your questions of concerns.

Elevator Pain Diagnosis – Our goal is to revolutionize the elevator industry and make improvements for everyone. We are not happy with the current reputation of the elevator industry and this is part of our ongoing effort to correct problems by identifying elevator pain. But, we need you! So please read on to help us change the elevator industry for the better.

The MEM Team

We have all been there. Sitting on a paper covered, padded vinyl table with nothing more on than a flimsy, backless gown that doesn’t fit quite right. As we awkwardly fidget back and forth, trying to get comfortable and avoid the cold spots on the table, we know there is something wrong that needs special attention.

We need to get rid of the pain we have been facing, but because we are stubborn or embarrassed or both, we tend to ignore the misery just hoping it will go away. As the constant discomfort begins to needle us more and more, we finally have to breakdown and try to do something about it. So we go to the exam room and after a long wait the doctor finally strolls in and the first thing out of his mouth is, “Where does it hurt?”

It is a funny question because we have already told the receptionist where it hurts, the nurse, our significant other, and anyone else that would listen to us complain. But now we are speaking to someone that can actually get to the root of the problem and make the pain, hopefully, disappear–so we tell our tale of woe.

It seems with elevators and construction projects there is pain as well, but there are no experts looking for the root problem to the pain we face. But no one doubts when it comes to a multi-story project there’s a sizable amount of it. Just like the pain we feel when we have a doctor’s visit, we have told countless others about the constant throb that drives us to the brink of insanity. It is real and not unusual as it is universal to the construction industry, yet the problem seems to be undiagnosed and outside of our grasp. In the whole of the construction industry, there is nothing that slows down a project more or creates more friction than the elevator. That said how do we get relief?

It starts with assessing the pain. The list of pain points is exhausting: “We were promised a fully functioning elevator in three months,” “The cost is not what was promised,” “I am being change ordered to death,” “I call and call and no one ever answers even basic questions,” “The bad weather is delaying the elevator,” “The elevator company has halted all other construction until they are done,” “Missing parts slows the project,” “It seems the elevator company is working against us instead of with us,” “Why must they take up so much room on the site?” and more and more and more.

Each of these problems are typical and create issues that mean delays, cost over runs, and pain for all parties involved. But we are going to start doing something about it. But we need you to tell us where it hurts.

You are a leader in the construction industry. It is why you get the monthly newsletter. And we are the largest manufacturer of modular Elevators. For too long there has been a disconnect between your trade and the elevator industry. It seems we are almost speaking different languages.

Both of us seem to be missing each other in the planning, coordination, installation and start up. But that does not mean we have to accept it or live with it anymore. We can improve and to do so we are looking for some help in closing the information gap.

Ultimately, we would love to put together a guidance document for elevators in general, establish a professional group and have open forums to assist both industries with coordination and integration. However, we know and understand the value of your time. So, to get the conversation started we were hoping a simple five question poll could get us pointed in the right direction.

We hope you will help. The elevator industry has not been a very good partner in many ways, so you will not hurt our feelings by being blunt. We know making systemic changes will take honest dialog and we are willing to listen.

Here is a link to the survey. It should take less than five minutes to complete. Remember it is a starting point and we will share all of the results to begin understanding each other.

Just in case you want to see what we do, you can click to schedule a tour. Or if you are intrigued by us you can get a fast track quote.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.