Schools and Modular Elevators – Newhart Middle School/Mission Viejo, CA. Innovation can be hard to accept. However, when it comes to education, there is a long history of embracing a revolutionary method when it comes to elevators.

As an example, in Mission Viejo they embraced innovation. First, they created a brand new STEM learning environment. It will serve the children of Mission Viejo for years to come. But second, they embraced innovation in choosing the MEM Elevator System for their vertical transportation needs. But, this is not unusual as the education sector has always been willing and ready to embrace new and better technology.

Newhart Middle School is not the first school to embrace a modular elevator by a longshot. We know this because schools have been a part of the Modular Elevator Manufacturing portfolio from the beginning. Historically, the modular elevator was largely designed to be a fast, easy solution to provide accessibility for schools. The need was huge and a fast solution was needed that met their timelines. The education vertical quickly realized that the new innovation of modular elevators was the best solution and as a result a partnership was formed. For over 20 years that partnership has grown and is still going strong today.

At one time and for nearly ten years our number one selling market segment was education at all levels. These projects include elevators for dorms, schools, parking facilities, stadiums, and press box accessibility. It remains an important part of what we do as we are providing more elevators for education than ever before, but other verticals have now picked up on the innovation we provide and have caught up.

Schools remain a large part of our business model because the needs of schools are the same when it comes to the elevators they choose. The benefits of our modular elevators meets those needs so well we are the natural and best choice.

With all those benefits it is not hard to see how other verticals have caught up with the education segment of our business.

Our success in other vertical markets comes from taking the lessons we learned in dealing with various school districts and applying them to every market sector. The results is our experience and willingness to improve has led to a superior product. And as it turns out every type of business, government entity, or building owner wants the same thing when it comes to choosing the elevator for their project.

They want an easy, yet reliable and high-quality solution for their projects. We can provide that whether it is new construction or a retrofit application; in an industrial setting, commercial property, hospitality or in a school.

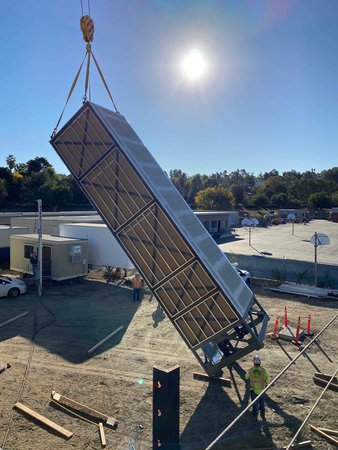

We have a solution that meets and exceeds your needs. That is what the people in Mission Viejo understood. We manufactured as elevator for them. It was delivered when they needed it. Set in place in a couple hours and started up in less than a week when permanent power was supplied. Below are pictures of the process.

What you are seeing is a fully installed elevator being placed through a hole that was left in the build. It was set in just a couple hours and was started up in a couple of days. Revolutionary!

As you can see, the project looks great. It went in faster and easier for the school with no disruption to classes. Also, it embraced their movement towards more innovation in all they do.

If you would like to see about this project or others like it, we are opening up our factory to live, virtual tours at your convenience. All you have to do is click the button and fill out a simple form. We will then schedule the tour at your convenience. During the tour we will answer any and all questions. You can also schedule an in person visit as well.

Lastly, if you have a project in mind and want to speak directly to one of our representatives fill out the Fast Track form. We can provide you a thumbnail number in hours.

For more great photos of the project, visit our good friends at Miller Construction. Their team did a great job!

Elevator Revolution – It really is that easy. Projects are complex with lots of moving parts. Electrical, plumbing, heat and air, structural concerns, finishes, the foundation, openings, and more needs constant monitoring and adjustment. The logistics of all those construction divisions suck time and resources from your busy schedule. This makes keeping everything on track, on time and moving forward more than a headache to say the least.

So, every once in a while it is a relief when there is a simple solution. A solution that takes an entire part of the project off the critical path, instead of placing it on the to do list. The MEM Elevator System does just that and makes it easy. It allows you to draw a line through that part of the building project and not think about it again.

It is a simple solution because with a modular elevator there are only two steps once the contract is signed, the purchase made and the pit is poured. The first step is a fully installed elevator delivered and craned into place. This step takes less than four hours and none of your time unless you want to watch it go in. The second step is once permanent power is supplied, the elevator is started up. This take around a week. This was exactly the process of one of our most recent projects, Los Osos High School.

Projects like Los Osos High School demonstrate our fast, high-quality solution through forward thinking and superior engineering. See, traditional elevator companies and other modular elevator businesses have significantly less experience or are just stuck in old thinking when it comes to modular elevator systems. Traditional elevators are anchored in the 60’s (the 1860’s) with no desire to upgrade their product models. With the modular elevator business, many elevator novices jumped into the market with little understanding of what makes an elevator tick. As a result they have no idea as to why installations are such a pain and certainly had no idea as to how to find engineering solutions. For them, often times, each elevator produced is an experiment that the builder pays for in real dollars.

But why should superior engineering matter to the developer, building owner, architect, project supervisor, or other building professionals? I mean really the most you really need to know about an elevator is when you press the button, it goes up. In simplest terms an elevator is just a box that goes up and down inside another box.

However, the engineering matters because that is what allows the installation to go in smoothly and quickly without delays and complications. The process is a success because what we say about a simple solution is true. And it leads to a headache free jobsite. Also, because of our expertise and knowledge we are able to accommodate special requests and special circumstances. Others run from projects that need to incorporate a corner post, or difficult applications such as inside the Spruce Goose Hanger for Google. Because of our engineering, knowledge and experience we enjoy the challenge and the results.

This was true on the Los Osos High School project. Everything went according to plan and according to the timeline that was most beneficial for the project. As we all know, schools have a difficult timeline to say the least. Even when it is new construction the calendar of the school district reigns supreme. That brings lots of pressure to bear.

With the project a fully installed elevator was delivered when promised. And it was up and running on time with no complications. Wouldn’t it be nice to know that the elevator is taken care of completely? That is possible with success through engineering and our knowledgeable team.

We have a well thought out approach when it comes to durability, quality, safety, and speed. That is due to our decades of experience in the elevator industry in both service and manufacturing. We know the challenges so you benefit from our years of knowledge. Bottom line, we know what it takes to design and build one tough elevator. But beyond that, we deliver it when you need it on the jobsite as a fully installed unit. Here are some videos showing how easy it is.

So, for your next project it maybe time to explore the possibilities of the MEM Elevator System.

To see how our experience in the elevator industry can be a perfect fit click the button below. We can provide a Fast Track Quote or schedule a LIVE VIRTUAL TOUR of our facility. We would be happy to pull back the curtain and reveal our process. It shows how we produce the industry’s most successful modular elevator solution.

MEM Cuts Costs as Interest Rates Rise/ Interest rates are on a roller coaster ride and that roller coaster is heading up. This is a very real, and can be a very damaging problem for the US economy and the construction industry. As the chart below demonstrates the march higher began prior to April of 2022 and continues to this day. The purpose is to slow inflation to around 2% by putting downward pressure on economic activity through Federal Reserve rate hikes. In other words if money becomes too expensive, then industries such as construction will slow. The economy does not shift at a whim especially when all the forces are aligned for inflation at this time regardless of Fed policy. The point is that this maybe a long trend and not just a blip. Inflation has been very sticky and continues to be.

So what can be done in the construction industry to combat high interest rates that maybe here for sometime? Borrow less. Our industry engages in long-term commitments and obligations with slim margins. That applies more pressure as we build, meet payroll and see operating costs explode as simultaneously financing those costs increase. Suddenly, we grasp for every potential savings available by trimming general costs and seeking alternatives.

The right alternative is a commercial quality elevator that has a long-term history of success and that can replace the need for a construction elevator on the jobsite. By consolidating the tasks of a permanent elevator and a construction hoist, costs can be significantly reduced. But, only an elevator fully installed at the beginning of the project and ready for start up early on can meet the need.

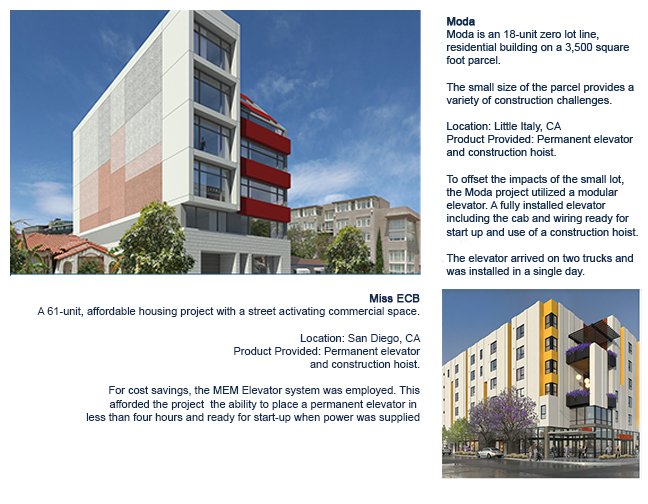

The MEM Elevator System can cuts costs as interest rates and inflation holds firm. Below are just two recent projects that we just finished installing where the permanent elevator doubled as the construction hoist. Not having to employ a construction elevator can reduce costs immensely. This option is not just a way to save during inflationary times, but just smart business.

In both cases the elevator unit or MEM System was placed early in the project. The system is designed to be self-supporting, so it is placed and awaits power, set up and inspection. Placing the fully installed elevator takes less than four hours and the set up portion of the project is usually less than a week in total hours. This makes it not only plausible to save significantly, but a certainty of reducing costs.

As you can see from the photo the elevator operates just like any other construction hoist with a set call box for access. We also go to great lengths to protection the cab interior. Protective panels and wraps are in place during the build. You can also see that it is not a project dependent on any one type of construction method. the MEM System is at home in modular construction to stick built applications.

Additional project savings are due to fact that the MEM Elevator System arrives with the elevator fully installed in the factory produced hoistway. This includes elevator doors and frames. That means no call backs on tape and mud crews, painters and flooring contractors. It is estimated that $40,000 per elevator opening can be saved on most jobs.

If you want to find out more about how choosing the right elevator cuts costs click below. You can either get a thumbnail budget number for the MEM System for your next project or, your can schedule a live virtual tour. During the tour we will pull back the curtain, so you can see how we produce the best elevator solution for all mid and low-rise applications.

Quality is crucial when it comes to anything we buy. That is especially true when we are talking about a commercial quality elevator. The stakes are high and a shaky elevator ride can give a person a lasting negative impression. But more than that a commercial quality elevator carries passengers. So there is a need for quality for the sake of the safety of the elevator riding public. Quality is important. Yet it can seem illusive as with most projects the elevator is the biggest moving object in the build and extremely complex.

Additionally, apart from safety and overall building aesthetics (feel of the ride) there are many others reasons why quality is so crucial too. A lack of hitting high standards also cost time and money on projects. We have all experienced a time when we made a purchase only to return the item for a replacement and then had to return it again. Frustration, waste, anger, agitation and disgust filled our minds as we get in the car for the third time. With quality there is assurance, peace, pride and pleasure.

So how do we achieve our high standards and why do we say “commercial quality elevator” so often?

First we tend to say it a lot because of factors beyond our control. Perception can be misleading, but in the minds of many a reality. With modular there is sometimes the perception that with the ease modular provides there must be compromises. The product in many ways seems to good to be true so mentally there is a leap to possible issues that don’t exist. We have been working diligently for decades to dispel that notion. In every project we produce we care deeply about quality and it shows. So in reality it is more of messaging to correct a perception may have had some grounding in fact, but is now decades past its shelf life. We are quality at MEM.

We also sometimes have pushback from a threatened industry. The monolithic elevator industry sees the writing on the wall, but due to their business model, they cannot extricate themselves from the traditional elevator build and installation. They have literally been doing elevators the same way since the mid-1800’s. No kidding. Elevator installation has not changed since the Civil War… our Civil War… in the US… over 160 years ago! In 1859 the Cooper Union Foundation Building had an elevator shaft built in (even though passenger elevators were not available). Then, once completed the elevator was brought into the shaft on piece at a time just like today. That model has not changed since. What other product on Earth has seen less innovation in its process since the 1860’s? Innovation threatens so they attack.

In a nutshell, the above are the reasons we stress our quality so much.

More importantly, how do we achieve quality? We can say we have quality and that quality is worth having, but all that talk is completely nullified if we can’t produce it. We do and I came up with five ways we assure quality with every project going out the door:

This refers mostly to the hoistway, elevator car and sling and other items we manufacture in house. The factory process uses templates, quality materials and well thought-out and practiced procedures. For instance our cab is tough Galvanneal steel easily produced to exact sizes by use of templates and guides. We would never use flimsy particle board covered in glued on laminate. That kind of cheap product is apt to warp, expand and flake.

This term encompasses the pride of the team members at MEM and their experience. It begins with the sales representatives. They are the most informed and knowledgeable people regarding modular elevators and elevators in general you can find. This is crucial as they guide the process from beginning to end. They set the pace and know each project completely and intimately. We also meet every jurisdictional requirement with licensed welders, electricians with years of experience and employees that have pride in their work. Lastly, we thoroughly inspect every elevator we manufacture with a 10 Point Inspection – Check List. Using that list a certified elevator technician performs the inspection. In this way you can be sure that when we ship an elevator, it is the quality we promise. We also provide consistent inspections through out the build.

Dirty little secret…they are all the same. It really does not matter the name plate on the control panel in the car. Every elevator contains roughly the same components. All the parts have to meet the same high standards regardless of the company providing them. High-quality standards are demanded and required by law, by jurisdictional code and by regulation. We abide by all to produce quality everytime.

Our factory process produces consistent quality. But that does not mean we are stuck in old ways or not flexible in design. We think though what we do, provide for flexibility and constantly assess how we can improve. We test and update our process as needed. Additional benefits including being inside a factory. Cold and heat do not interrupt our manufacturing, nor do they act as an impediment to consistency. Whether we like it or not if it is snowing outside at 20 degree, traditional construction suffers. This is seen every time a traditional built hoistway it not plumb or level. Our building practices are perfect every time and on time every time.

Two quick points. Our design is based on more experience than any other modular elevator company. Also, the engineering is improved consistently over time. We have made design improvements that others have not. Also, not only do MEM elevators meet the engineering standards of difficult Seismic areas, they are also used in high wind or hurricane areas. The MEM Elevator System is also designed for more efficiency in installation and setting the elevator. Our experience in the industry makes us the leader in design and engineering.

When we say our team has a fully-installed commercial quality is set in four hours we mean it. The same goes with start up. When power is available we can have your elevators running in a week. This is due to our superior quality. Our team consists of elevator people through and through. Passing inspection easily is the rule because of the design, engineering, production process and quality.

It is one thing to talk about quality and quite another to see it. So we invite you to see it firsthand. You can click below to schedule a LIVE VIRTUAL TOUR. We will pull back the curtain and let you see what we are doing, how we do it and why it is the best option for all low and mid-rise projects. The difference in quality will be clear. Of course during the tour you can ask any questions you want. We are open with our process and proud to show it off.

If you have a project in mind already click the button below for a FAST TRACK QUOTE. We will contact you for additional particulars, but will provide you with a budget number with in 24 hours. There of course is no hard sell or obligation. We just want to be able to answer your questions, find out your challenges and help be a solution. That is how we are a part of the elevator revolution.

Modular Elevator Inside or Out – One of the most common questions we get asked is, Can you place the MEM Elevator System on the inside of a project? The reason for the question is more than likely what you see most in photographs of modular elevators and on our website elevator on an exterior wall. We tend to do that so people looking at them can clearly see the elevator and that it includes the hoistway.

See, a modular elevator is a manufactured elevator hoistway with all the elevator components factory installed, so showing the hoistway seems to make sense. However, that has led to the common mistake of thinking that they can only go on the exterior of a build.

Most recently two of our elevators were placed at approximately the same time and as you can see in the video below there was one of each (outside and inside). That is probably about the percent when it comes to new construction. Exterior placed elevators probably hold a slim edge, but overall as we produce only high-quality commercial elevators and they can be placed anywhere. This is especially true as they are self supporting structures.

Now when it comes to retrofit projects, where the customer is adding an elevator to an existing structure, we do many more exterior applications. But that is not because of our product. It is due to structural needs and spatial requirements for the project. An exterior elevator usually makes more sense and is a better solution.

In the photographs for this blog post you can see the interior application. In the 5 – story dormitory project at the University of La Verne, you can see our fully installed elevator hoistway going smack-dab in the middle of the building. Not only that, if you look at the conceptual drawing you won’t see even a hint of a hoistway. The duplexed modular elevators were simply placed on the inside of the project.

Also, note that the elevators came in sections. Each section can generally be up to 50 feet in height. But, because of the revolutionary stackable design we are not held to 50 feet or less. As a matter of fact they can be designed for most low or mid-rise applications.

For the La Verne project, the elevators went in during the construction phase. However, due to the flexibility of modular elevator units, they can be set at anytime. For instance, with the interior elevator in the video it could have been placed first, but the project manager wanted the bulk of the project standing before the elevator went in. They just left us a hole and our elevator simply slipped into place. That is less common as most often construction managers like to move the process of craning the elevator into place to the beginning. The set takes place right after the foundation work is completed and the pit is poured. They like to see the elevator portion of the project done and out of the way with only a startup needed.

As you can imagine, a fully installed elevator set in just four hours revolutionizes the elevator and multi-story construction industry. That is especially true if it is at the beginning of the build. Once placed the commercial quality elevator waits for the rest of the project and off the critical path instead of the other way around. When power is supplied it is ready for startup. This means they can be used as construction lifts.

Also remember there are other benefits as well:

For instance there is no need for setting aside space for elevator mechanic tools or components. Modular Elevators are safer than having an open elevator shaft on the jobsite. They are greener as well with less onsite traffic, less scrap and more recycling. The revolution has begun. It is time to consider modular.

If you are impressed with the concept or timeline or have more questions. Join the revolution by clicking the button below. We will provide you a Fast Track thumbnail quote in 24 hours. Feel free to start a conversation by providing some details on an upcoming project. You can also sign up for a virtual live tour. One last thing, a big thanks to our friends at Steinberg – Hart for a great design!

MEM – Leading the Elevator Revolution.

For nearly twenty years Modular Elevator Manufacturing has been leading the elevator revolution. Like any revolution there are milestones or measurements that show the growth of that movement. Markers that point to the “normalization” or general acceptance of a movement. These include: a global awareness of the product and methodology, an overall increase in market acceptance, implemented examples of the concept in completed projects, general acceptance and understanding of the advantages, and ultimately expansion of the market. Now, MEM is pleased to say, “Next stop transformation”.

Those milestones are being realized. Now the focus is shifting from the necessity of revolution to the reality of transformation in the elevator industry itself.

When the concept of the modular elevator was first conceived, it was as a response to the Americans with Disabilities Act (ADA). Three individuals put together the original plans and started producing modular elevator units. Their concept was largely designed to sit beside an existing structure to easily and quickly make an old building compliant and more accessible. Great idea!

Many of those early units were sold and installed. But a modular delivery approach requires an understanding of construction and elevators. Ultimately, an overall lack of experience in the construction industry led to many difficulties in the installation process along with other issues. However, suggestions from the field for improvements often fell on deaf ears and so the concept, although sound, struggled to take off.

Enter TLShield. As the fledgling modular elevator company fell to failure, Tom Shield, who had installed many of the early units, took a bold step. His company, TL Shield and Associates began a new entity Modular Elevator Manufacturing (MEM) dedicated solely to the improvement and production of modular elevators. They instituted many product changes to improve the overall quality and installation process. The MEM Elevator System was born and they began producing the solution that many were looking for.

Since that time a steady march towards revolutionizing the old, tired model of conventional elevators began. Few realize the elevator industry had largely remained stuck in the mid-1800’s in the way an elevator was installed and produced. Since before the Civil War hoistways were built in a building and then the elevator was painstakingly assembled in the shaft. Crates of parts would arrive to be assembled in a closed, challenging space. That is still the way it is done in the conventional elevator sector. In an honest moment, the entire industry would agree, that makes no sense at all. Modular elevators changed all of that. They are produced in a factory, hoistway and all, shipped to the location and then the fully install elevator is lowered into place in a couple hours.

Since the beginning MEM realized that the product was revolutionary, but the revolution could easily die if a proactive approach to enlightening the construction industry failed. So education and information became the model to market the concept and high-quality product. “Next stop transformation” would take time, patience and effort but worth it. Change in any monopolistic industry is a slow steady undertaking and does not happen overnight.

To propel that change forward, the new model became education in place of the expected sales pitch. Older iterations of the MEM website contained a voluminous amount of data, facts and specifications. It even offered up links to drawings and engineering information. Previously many considered that kind of information proprietary to their brand and did not have plans on line. However, we found transparency was the best option in how we arrived at our improvements, created awareness and helped to answer questions.

This includes passing knowledge freely to other elevator companies. Sharing and opening our facility became a routine practice and is still in practice today. When Covid hit, we offered for the first time a one of a kind virtual tour of our factory to anyone that asks. That openness and outreach remains the only online virtual tour of an elevator production facility in the world. No one opens their doors as we do. We know allowing openness and full disclosure is the only way to make our “next stop transformation” a reality.

If you want to take advantage of our live virtual tour you can do so. Just click the button.

Early on schools in California embraced the modular concept and the idea that a modular elevator would be the best and most logical choice for ADA compliance. As the sole leader in the industry we were often specced into those projects. However, I remember the day that a modular elevator was specced into a project that was not in the education sector. Obviously the day passed with no fanfare or popping corks, but I knew things had changed.

Product acceptance on a whole new level had just occurred. That was followed quickly by approved architect training through AIA, integration into new building projects not just retrofits and design/build plans being altered. This was all to incorporate our modular units into ever-widening applications regardless of the type of construction method.

We also found that big players in the construction industry were more than just curious, they were serious. They saw that a fully installed elevator set in place before lunch break was a big deal. The realization and reality of an elevator off the critical path had enormous implications. The potential of that removal from the critical path changes everything. It reduces call backs of other trades, keeps everything in sequence, and smooths the entire timeline and costs. Suddenly, the light bulb clicked on…there was a better way.

Acceptance of the product was also demonstrated by increases in our Fast Track quotes, formal quotes and ultimately sales. In just the past two years we had to double our manufacturing floor and we are currently at all-time sales heights requiring us to look at an additional expansion or space. We now ship nationwide routinely with projects as far away as New York. All of this success was due in part to our commitment to modeling of the concept in how it works and the advantages.

Commonsense it seems has disappeared in some ways from our society. The hardest way of doing things has replaced ease and wisdom as in the construction industry’s use of conventional elevator companies. Unfortunately, their sales concepts is not one of openness and sharing. Instead we learned through our polling efforts they were sometimes sowing seeds of confusion an exclusion. There was just one way…their way.

“The elevator company knows there are not many alternatives for installation so they capitalize in the safety of us needing them more than they need us.”

Poll Respondent – August 2022

One of the respondents to our poll said it best, “It’s unfortunate knowing when entering into a project where elevators are to be installed that there will be issues and complicated schedule situations. The elevator company knows there are not many alternatives for installation so they capitalize in the safety of us needing them more than they need us.”

We have become that alternative and change so needed. As our mission is not just to offer concepts, but actual projects that clearly demonstrate higher quality can accompany speed through manufacturing.

It is a huge difference as we recognize that we have succeeded where the previous company failed by listening, understanding the elevator industry intimately and making needed change. Intuitively we knew immediate improvements that would make everything better in the engineering, design and installation. Honestly some were what we would call no-brainers, plain to see from the decades of elevator experience we brought to the table.

However, it is easy to be blinded by past success. So we continue to innovate, expand our knowledge and to assess our projects from the perspective of architects, project engineers, construction managers and owners. The communication is crucial.

It is important to know that this does not mean every idea is a good idea. We methodically look at new ideas, designs and product lines against what has worked. We think deeply and don’t jump to quick conclusions. This has led to an ever improving product line that exceeds expectations.

As our market share of elevators continues to grow we know our ideas and concepts will be and have been copied. Sometimes they are just pretenders that think anyone can produce an elevator. They struggle with quality and often seem to grope in the dark with innovation. But, when you are driving towards the “next stop transformation” philosophy ultimately the next stop includes others in the business. When you are successful at what you do people will follow.

The result is two new reputable entrants into the modular elevator industry. They have seen growth and want to be a part of the revolution. It may surprise you but, we have no qualms with that as long as they copy our quality as well. As a pioneer in the modular elevator business we are glad to have help building on what we have done.

Resolute Elevator in North Carolina has stepped up to manufacturing modular elevators in a big way and they are seeing great growth. Their background is similar to ours. They were in the elevator business for several years and even installed some modular elevators. Likewise, they were concerned for the elevator riding pubic and the concept itself when they found the modular offerings they used less than the quality they and their customers demanded. At Resolute they felt innovation was lacking and poor workmanship was the order of the day. They understand that if modular elevators become equated with substandard quality then the better concept of a manufactured elevators would struggle. They have even participated in one of our cohort groups. Their input was invaluable.

Big congrats to them and best wishes!

But a second entrant into the modular elevator industry is more curious. Thyssenkrupp (commonly called TKE), having witnessed the wisdom and potential market share of modular, has decided to stick their decidedly big toe into the elevator revolution we began so long ago. As we all know big companies move slow and ponderously and big elevator is no acceptation. After all we have been grabbing more and more of the elevator market for over a decade and our innovations have now become a staple in many construction segments.

Why does TKE embrace change now? One can only speculate. However as we know in the “next stop transformation” theory, new entrants will come from a number of sources. We are just satisfied that they, although late to the party, see that modular is viable and the future. They are just now testing their new modular system in Hong Kong, but they will eventually make it to our shores. This is not just vindication, but product justification. Now they see it and soon everyone in the construction industry will as well.

Overall this is proof positive that what we are doing is winning the revolution.

Next stop…transformation and we have been leaders in that effort longer than anyone else.

If you are interested in being a part of the elevator revolution, we encourage you to dig, explore and ask plenty of questions. We are ready and willing to be a part of your period of discovery. To get started we offer a couple opportunities below. Just click a button.

Best Argument for a Modular Elevator – I am very lonely in my job as a marketing professional in the world of modular elevators, because at last count, I am it. If there is a new one out there, welcome to the revolution. But, for now its just me.

The reason I bring that up is single handedly I have written hundreds of articles supporting the modular elevator industry and I am on the constant look for two things. First, a new perspective or way to spark interest, hone my argument or new way to discuss the modular elevator industry. Second, help. This comes in the form of any supporting information, blogs, studies, whitepapers or reports. I scour the internet and other resources constantly and as a result, with the help of one of our team members, ran across a great new article. It was surprising help from an unlikely source.

A LinkedIn contributor that goes by Dr. Michael Simmons, DBA wrote a very concise and clear, step-by-step description of what a typical hydraulic elevator installation looks like. This is not a modular installation mind you, but a traditional run-of the-mill elevator install. The article is entitled How Do They Do It? Hydraulic Elevator Edition and I encourage you to take a look at it. It is 1000 words of exactly all the steps that have to take place to install an elevator with the traditional installation method.

So why did I find the Best Argument for a Modular Elevator in an article about a regular elevator installation? Because it proves beyond any shadow of doubt, in simple and clear terms, the lunacy of traditionally installing an elevator. The antiquated process comes with a myriad of problems and challenges that frustrates the building owner or build team. Below are just some challenges taken from the article.

These are just a few of the potential injury risks, ways the project can be delayed, inefficiencies that come with the the process and challenges regarding quality. Modular elevators are completely different.

With an MEM Elevator System the commercial quality elevator is manufactured in a factory with quality controls and constant inspection. First, the hoistway is built with jigs and precise templates to assure it is always plumb and level. Once the hoistway is finished and wrapped in drywall for fire protection according to code, doors and entrances are factory installed.

Meanwhile the elevator sling and cab are being built in a separate location in the factory. High quality Galvanneal steel is used for the cab walls to ensure durability and longevity. During assembly our build team can freely walk around the cab as it is being built and precise jigs are used to ensure a perfect fit in the hoistway everytime.

The wiring is complete in the factory as well.

The last step is to insert the cab into the the hoistway. Done.

The benefits are tremendous. The quality is higher, inspections can be completed throughout the process, it greener as there is less waste, and there is no interference with other trades or reliance on others to complete the elevator. When you need it, it is craned into place and that’s it. The process is so fast the elevator can be used as a construction lift saving even more time and money. You get the elevator when you need it not at the arbitrary timing of an elevator company.

If you took the time to read the article that gave me significant help and inspired my post, think about it. All of the headlines in the article contain the various steps of a traditional install. With modular elevators they can all be skipped! No headache for you as you can simple draw a line through elevator on your to do list. We take care of everything making it the easiest way to have an elevator in your building. The only step we need is adjustment and inspection once power is on. That’s it. You get to skip to the end.

This means that the elevator is off the critical path and not getting in the way of all the other trades on site. Also, crews won’t waste even a second waiting to finish around entrances. That work can be done in sequence. Lastly, this means you save time, money and countless headaches. It is the best argument ever for a modular elevator.

As you can see, the modular concept for elevators is revolutionary, but this concept is not new. We have been at it for a long time and have hundreds of elevators installed nationally. Also, we are pioneers in the elevator industry seeing a need and creating a great solution. The old elevator industry needed improving in safety, quality and fast start up and we did it. Something that would takes weeks with traditional installation now takes a few hours. Its time to join the Revolution.

Click the button below to get a Fast Track Quote or if you want to explore a bit more request a live virtual tour. We will pull back the curtain and show you how we produce the MEM Elevator System.

Hope On Hyde Park/Los Angeles, CA – Mission accomplished. The Hope On Hyde project is a great example of everyone pulling together for a great outcome. Our small part for this affordable transitional housing community for the Los Angeles area is complete. As a result we thought we would look back at the project and the team that brought it all together.

Of course MEM had a great install team with TL Shield & Associates taking charge of the placement and start up process. C. W. Driver led the way with the overall project leadership and they were grateful for our participation. “We appreciate MEM’s experience in the elevator industry. They helped keep the project moving forward and on time.” – John Kately, Project Executive, C.W. Driver. Lastly, KTGY provided superb architectural plans, drawings and concept.

It was a team effort with us playing just a small part of the overall effort and we are overjoyed with the results.

The project was a modular build from the beginning. So, using a conventional elevator can defeat the overriding premise of using the modular concept. Modular is supposed to be faster than conventional construction. There are other positive factors such as it being safer, greener, higher quality and more cost effective, but the first thing people look at is speed to completion.

We helped with the timeline because if you have a modular project with a conventional elevator, the work can easily grind to a halt. The elevator is smack dab in the middle of the critical path and conventional elevators interrupt the general construction process in the following ways:

For all the above reasons and more, for a modular project the only solution is to place the MEM Elevator solution.

The five-story development will offer studios and one-bedroom apartments on a 0.49-acre site. Residential services and a boxing gym will be located on the ground floor. The 98-unit building will be constructed around a central courtyard, providing privacy, safety, and a deepened sense of community. Parking spaces will be provided for social services staff while each resident will have a bike storage space. Floor to ceiling glazing along the amenity space will engage the community and brings movement to the street.

The elevator for the five-story project, as you can see in the video above, was set in no time. Quite impressive even for veteran project managers. “Seeing a fully installed elevator lowered into place and set in four hours was amazing.” – Luis Cadiz, Project Manager, C.W. Driver.

The process begins with placing the mode of conveyance, an in-ground hydraulic jack. It goes in first. Then the lower a portion of the fully installed elevator and hoistway gets craned into place. Once it is set, the second section of the elevator is lowered as well and locked in. The elevator came in two sections due to transportation needs and is not unusual in the least. The units are designed to be stackable.

The entire elevator set took less than four hours and everything is already inside including the elevator car and wiring. Once power is available onsite the MEM Elevator System is ready to go. It will then be started up, adjusted and scheduled for inspection. An easy, fast, timesaving solution. The elevator is off the critical path and the all too important purpose of the building can begin changing lives sooner than if a traditional elevator was used.

TL Shield & Associates set the elevator and will be in charge of start up as well. They and Modular Elevator Manufacturing was chosen due to the expertise they provide and the superior product they offer. They have been the leaders in the modular elevator field for more than two decades.

Tough steel makes up the MEM Elevator System hoistway with production occurring in a factory environment. Installation of all the elevator components and parts then takes place. Loading and shipping occurs next when the site is ready. In four hours you will have a fully installed, commercial quality elevator ready to be started up and used.

The mission of this project is important. The elevator and the Hope on Hyde Park project are crucial to combat the growing homelessness issues in Los Angeles. There are several benefits for supportive housing with the MEM system:

In conclusion, it maybe time to explore the possibilities further regarding supportive housing elevators. Let’s see if the MEM Elevator System can meet your needs. You can click the button below for a Fast Track Quote for a project you currently are working on. However, if you want to explore it more, request a LIVE VIRTUAL TOUR. We would be happy to pull back the curtain. We will show you how we produce the industry’s most successful modular elevator solution.

National Distribution Network Means Modular Elevator Manufacturing (MEM) Growth. In the past year due to our growing distribution network our high-quality modular elevators have been placed from California to New York. Now we welcome Georgia Lift Solutions to the MEM Authorized Elevator Contractor team.

Our friends Kyle Floyd and Dillon Graham from Georgia Lift Solutions have now partnered with us as an Authorized Elevator Contractor (AEC). Both came to our headquarters and factory for orientation, training, and instruction on the MEM Elevator Solution. They see the benefits of going modular and are looking forward to engaging with us as they grow their organization. This will further increase demand for the MEM solution and we are ready to meet that demand with even more AECs nationwide.

The elevator industry revolution continues through our network of elevator installers because the MEM Elevator Solution is perfect for schools, commercial space, hospitality, medical facilities, multi-family units or parking structures. So regardless of the vertical market, MEM can provide a solution from the east coast to the west coast. Modular elevators are also perfect for any type of building project from modular to stick frame and can go on the interior or exterior of any project.

That flexibility expands the types of projects that our AECs can participate in and promotes an ever-expanding market.

MEM President – Tom Shield is glad to welcome Kyle and Dillon and are proud of growing the network of partners. “After 40 years in the construction business and over 20 years in the elevator manufacturing industry, it was time to allow our product to be installed through AECs nationwide. We have a great team of installers that know elevators inside out and we welcome Kyle and Dillon to that team.”

He went on to say, “It is our philosophy that good business is quality business. Georgia Lift Solutions brings the same desire for quality to the table.”

The AEC program will continue to grow and will provide even more opportunities. Shield said, “We are currently looking for more elevator businesses to be a part of the program so now is the time for exploration and inquiries. We provide the training, information, marketing partnerships, and support. So we both help each other as we grow. It is an exciting time for our industry.”

The modular concept for elevators is revolutionary. MEM is a pioneers in that industry that saw the need for safety, quality and fast set and start up. To summarize the difference between modular and stick-built…there are none other than the delivery method.

Modular elevators are a factory built hoistway with tough 4X4 inch HHS (Hollow Structural Steel), wrapped in mold resistant drywall. This is done to the customer’s specification. Then all the elevator components are factory installed. That means when they arrive at the site the wiring, cab, rails and other components are already inside the structure. It is then placed with a crane at the job-site in the elevator pit in less than a day and then can be started up in less than a week. This means that it takes the elevator off the critical path saving time, headaches and hassles for the customer. For the installer it means all the heavy lifting is already done and the time commitment for a project is minimal.

Something that would take weeks conventionally can now be done in days with the MEM solution.

If you would like a budget number and be a part of MEM growth on a project you currently are considering, click the button below to get the process started. You can also

Disney, the world class entertainment company, prides itself on cutting edge solutions, quality, and consistency. So, it is no wonder that the House of Mouse has found a solution to elevator woes. Modular elevator and Disney are a perfect match. But they are not alone. Everyone in the construction industry is constantly trying to find a way to deal with slowness and unresponsiveness of the traditional elevator companies. Disney found a fully installed elevator can be placed on the jobsite in less than four hours.

As you can see in the video to the left, the elevator arrives on a flatbed truck with the elevator jack. The jack is then placed in the pre-drilled hole and then the fully installed elevator is lowered into place. Everything is ready to go from the doors and entrances to awnings on the exterior. All the wiring is already in place as well as the fully constructed elevator car.

This is the perfect solution for any low or mid-rise application. And the MEM Elevator System is not just relegated to modular projects or parking garages.

The Disney project was specifically for a resort that needed access to a parking garage. However, the flexibility of our modular elevators goes far beyond that limited use in both type of construction and vertical markets.

For instance our elevators have been used in affordable housing projects, educational institutions from elementary schools to major universities, medical facilities, commercial buildings, and more.

When it comes to types construction for a project, there are no limits. Do you have a stick built project? We can be your solution. Modular? We are a perfect fit. Steel frame? Absolutely. And of course concrete construction.

How can there be such flexibility? Because in most cases the MEM Elevator System is designed to be a free standing structure meet all local codes regardless of earthquake or wind concerns.

Our Elevator System is flexible enough for any design challenge. So, contact us and be a part of the elevator revolution we are leading. For more info on solutions for you, click the button below for a FAST TRACK QUOTE. If you want to explore more just sign up for a LIVE VIRTUAL TOUR of our facility. We are open and willing answer questions and have discussions on viability for your project.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.