Elevator Wild Cards – We have all been in a friendly game of poker. In my youth I would spend hours with middle-school friends playing penny ante poker, usually in a dimly lit and musty smelling basement. To make the game more interesting, we would employ all sorts of wild card variations. They went from the mundane deuces wild to one-eyed-jacks and suicide-kings. Then there was my personal favorite, jacks-n-fives (big fan of the Jackson Five in the early 70’s).

I remember often sitting smugly with a wonderful natural hand raising as I went. In my clutches was a full house; hard to beat indeed. And to see those two nines and three queens staring back at me from my tight little grip gave me nothing but confidence. The result was a heaping mound of copper coins and the occasional nickel in the pot waiting for the final “call.” A world of wealth and pride for a 6th grader in 1975.

Like a scene from an old western I would lick my lips with anticipation and then spread my cards, declaring “Full house!” Only to be out done by two wild deuces and two lowly fives, four-of-a-kind. Rats, beat again!

We had lots of fun but, I came to the conclusion pretty early on the word “wild card” was a negative. It was not a positive term at all because it altered the game. Using them took a competition of skill and chance to a child’s game of pure luck. And, there is a difference. One is a challenge that can be calculated, anticipated, played with strategy and an understanding of rules and agreements. The other was completely blind and random.

So let’s openly show our cards for a second as we get the elevator part of the blog post.

In the serious business of construction, how much do you want to rely on chance, pure luck or wild cards? The building industry is highly reliant on calculation, anticipation, organization, strategy and agreement. Luck or wild cards should play no part, but it does. Every time you contract with a traditional elevator company job completion becomes blind and random.

It is the nature of how the elevators are installed in the old-fashioned way that makes them so untenable and unpredictable. Let’s face it, you do your end of the work. The hoistway and pit are made ready according to specs. There they sit for months. Because, once the cement dries you lose any and all ability to complete the elevator on your time schedule. And now your project completion rests with an elevator crew showing up when they want, completing the work on their time schedule not yours.

Instead of a fair game where everyone knows the rules you end up playing poker with a dealer that can make up cards wild at their discretion. You might as well throw out all of your laborious planning and scheduling.

Your strategy becomes the hand you were dealt. Begging, pleading, arguing, yelling, threatening and coercing are the only tools at your disposal. There is only hope and nothing is in your control. For the proactive project supervisor or superintendent this becomes maddening to say the least.

All the planning goes out the window. Not only do you have to wait for the elevator on someone else’s time schedule, you have to work around all their tools, elevator components, excuses and the elevator guys when they decide to show up.

But beyond that, due to the traditional elevator process entrances and door frames go in last multiplying problems. It falls to you to reschedule or call back the rock and tape crew, painters, floor prep and flooring contractors, even electricians and sprinkler workers. They are all delayed until the elevator is finished.

But there is a better way. What if the elevator were 100% in your control with no wild cards? You decide completely when the fully installed elevator is placed. Beyond that what if that elevator could double as a construction elevator?

Suddenly you could have all the trades pushed forward in sequence as all the entrances arrive completed, not when the elevator contractor can get to it. The result is a significant savings (click here for an amazing account from a project superintendent).

The MEM elevator system can make that happen. The commercial quality elevator and hoistway arrives as one finished product off of our assembly line. It comes on a flatbed truck when you want it. Here’s a video of one being placed. Your responsibility is largely the pit poured to our specifications. You tell us when you want it to arrive. That’s a big deal in an industry that thrives on timelines and completion. All that is needed regarding the elevator is time for start up and inspection.

In addition to the dollars and cents savings, there is an overall reduction in the mental stress and aggravation caused by traditional as well. There is peace of mind knowing the full installed elevator is placed often at the beginning of the build.

The benefits are clear and going with MEM is no gamble. We have been providing the best elevator solution for low and mid-rise projects for decades.

Also, there are no limits to the types of projects that we can assist with. The MEM elevator system can be used in new construction or retrofit. We have simple models for ADA compliance to full-sized hospital elevators. Our elevators can be used in parking garages to apartment complexes. Anywhere a traditional elevator can go we can too, only you control when it is delivered.

So end the high-stakes gamble on traditional and go with the your best bet; the MEM elevator system. To get started, click the button below to get a budget price or schedule a virtual tour of our factory and see how we consistently deal a winning hand.

Elevator 101 is about the basics. See, being around elevators all the time can warp your perspective. You begin to think that everyone has a pretty high base knowledge of elevators and elevator lingo. We tend to forget that most people’s knowledge of elevators in the construction industry is limited to, “They are a pain in the rear end”. So, every once in a while it is a good idea to review what the basic terms mean. Reviewing this info is especially needed if you are going to be chatting with people in the elevator business about a specific project.

Overall there is too much jargon. Like talking to a doctor or lawyer, elevator people sometimes skip over things that are basic to them, but may confuse folks not immersed in the field. The intricacies of brain surgery or the meaning of habeas corpus (I think its a city in Texas), can easily pass us by and so can terms regarding elevators. We hope this will help.

So here is a list of basic terms that you should review, or bookmark before you talk with an elevator consultant, elevator sales person or even an elevator mechanic.

That above list is a good staring point. However, if you ever have a question feel free to call us whether you have the intention of buying a modular elevator or not. As geeky and weird as it sounds, we like talking about elevators.

Below is a handy diagram, a chart based on travel distance and some links.

Additionally if you want to know more about the modes of conveyance. Just click here for a full explanation. You can also click here for information on hydraulic units. You can also look at the dozens of articles we have available on our blog.

If you would like to know a bit about pricing for a project just click the button below to get a Fast Track Quote. But if you really want to know more about elevators, schedule a live, virtual tour of our factory. It is open to anyone with questions about elevators. We love showing off!

Elevator Placement. You have a low or mid-rise project ready for the design phase. One of the first considerations is elevator placement and location of the stairwells. Because this happens so early it is crucial to get right. As we all know making a changes later in the game can be extremely difficult and pricy. Often times the knee-jerk reaction is to plunk the elevator down in the design nearest the main entrance or center of the building. But, deeper thought is needed.

Especially with the surge in modular buildings, the hoistway and staircases are being used less often for structural support in many circumstances. That is not saying structural support by the shaft and stairwell is no longer needed. At the very least all hoistways should be able to handle some gravity loads associate with floor tie-ins.

Shear loads are something completely different and have to be accounted for in the structural design. But, mankind was designing successful buildings without using hoistways for support for hundreds of years before the advent of the elevator. So using the hoistway for that purpose is not always necessary, but the best option depending on design. Just keep in mind, especially in low and mid-rise applications the need for structural support (gravity or shear) may have to be examined before changes of elevator placement is made.

In addition to the structural aspects of the project, you should also consider where people are wanting to go inside the building. After all, if elevators are a matter of convenience and mobility, it makes sense to put the elevator where use is most convenient for the most people. Blending the two considerations of structure and traffic flow can be an art form! But where can you get started to determine placement?

So with all that said here is a list of considerations as to elevator placement:

The above is not a complete list of considerations. It is just a starting point to get you thinking more about the need and purpose of the elevator itself. Far too often in this copy and paste world, the largest and most expensive moving object in the building becomes a second thought. For more insights here is my cheat sheet for number of elevators per building that may help.

Remember the project architect and engineer are great resources to answer your questions. Even if placement is copied from previous jobs, there are reasons for where they put the elevator where they did. So ask early “why?” and if you have additional concerns express them. Nothing is worse than getting months into a project and then wanting a change. I have never met an architect or engineer that didn’t like explaining the reason they made a choice.

Lastly, an independent elevator consultant is a good idea if you have questions. They will examine all the aspects of the building from the perspective of an elevator expert. If you need help finding a consultant we will help you do so. We work with many of the best.

Also, our team can go through your concerns as well. Everyday we answer questions as the only elevator experts in the modular industry. To get the process started just click the button below. The Fast Track quote form will ask some simple questions to get us started, just fill out the info as best you can. You can also sign up for a live virtual tour of our facility. We will answer your questions about how we produce high-quality commercial elevators right in our factory, that gets shipped and placed in a few hours and started up in a week.

Another win for the team at Modular Elevator Manufacturing! An MEM school elevator was placed at Fred Kelly Stadium at El Modena High School for the Orange Unified School District. The completed stadium replacement was built by Byrom-Davey, Inc. With the architecture completed by – HED Architects.

It was great working with the school district who did a phenomenal job with the project, Byrom-Davey and HED Architects. This team was filled with professionals that truly cared about the end product and it shows!

Below are just some of the videos including the virtual grand opening that was held during the Covid pandemic. Great video, but we cant wait until the stadium is full with cheering fans this upcoming school year!

The video below shows the elevator at about the 23 second mark.

Additionally the video below is a virtual tour of the project. The MEM school elevator is highlighted at the 1:00 mark. The lit hoistway is impressive to say the least.

Also, a virtual grand opening below discusses the benefits of the elevator when talking about access at the 7:30 mark and it is show again at 19:15 when giving a tour of the press area.

Again, what an impressive team and fantastic completed project!

For more pictures of the project and the elevator we encourage you to go to Architect Magazine.

If you think you could benefit from a high-quality commercial elevator for your project that installs in just 4 hours, click the button below for a quote. Or, you can sign up for a live virtual tour to see how we create the easiest and fastest installing elevator in the business.

“Elevator” and “delays” are two words you should never read in a headline. But in Abilene, Texas that is exactly what happened. The editors of the Abilene Reporter News were a little more creative than most by declaring, the school was “hoping to avoid the shaft” but you get the drift. Unfortunately, elevators delaying construction is far too common across the nation yet wholly unnecessary. There are more modern approaches to elevator installation that eliminate costly delays. You just have to avoid out of date construction methods.

The news article clearly points out why the elevator industry is moving past onsite installation. Schools like Austin Elementary deserve a better process.

People now realize that placing the elevator installation last in the process is fraught with problems and potential delays. This is precisely what happened in this Texas school. The timeline of the project had to be altered.

In this particular case all the other construction was generally completed with minor touch ups and landscaping left to go.

Then the elevator company decided to order the various parts and pieces. Seemingly the crates of components were delayed somehow. But, with the elevator installation at the end of the build, delayed ordering is only one possible stumbling block. There are several potential pitfalls that must be avoided to keep the project on time.

Just as likely a delay can be caused by damaged materials, crates being sent to the wrong address or missing parts. Not to mention materials being damaged during the elevator installation process itself. This can easily happen because onsite installation means that everything in an elevator shaft has to be carried in one piece at a time and then screwed, coerced, and cobbled together.

This all happens in a tight and crowded shaft. It makes no sense at all to do it that way, but that is the process.

Because some of the parts, like rails, are extremely heavy a dropped one can damage more sensitive components. Keep in mind damage does and will occur during the installation. Parts will be broken. It is just a question of if the parts can be easily replaced or hidden from view. That is not to mention all the injuries that can occur due to the manual lifting involved, falling or getting stuck between the various panels and the walls of the shaft. This bogs the crew down.

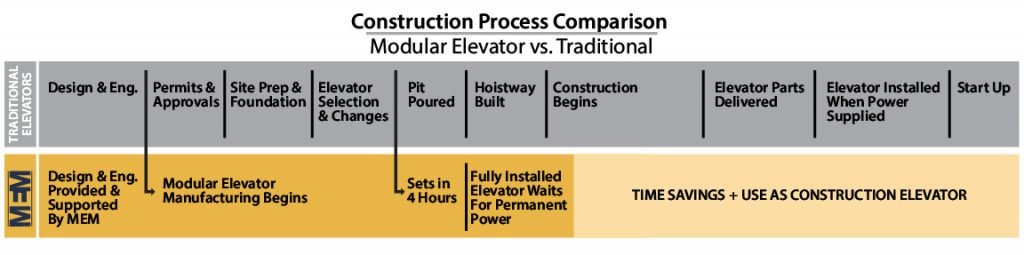

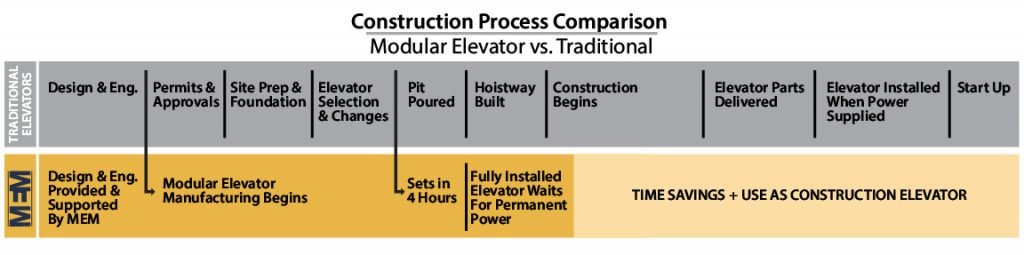

The solution is to have a more up to date installation processes in a factory setting. Then the elevator could be set in place first, avoiding any possible delays. This also cuts the timeline for the entire project. You can see the difference in the chart below. It lays out the difference between the traditional elevator process in gray. And the MEM elevator process in gold.

As you can see it is better to install in a factory, with no heavy lifting and all the parts are readily available. When the project manager wants it the elevator arrives. In less than four hours a fully installed elevator is in place.

Also, if you desire it can be used as a construction elevator.

This process produces higher-quality elevators with factory production that allows for consistent quality control and inspections. The improved process is simply faster, greener and smarter.

Lastly, old-fashioned elevator companies haven’t changed their process since the Civil War. It is that outdated, dangerous and often causes costly construction delays.

Our system has been revolutionizing the elevator industry for over 20 years with a success rate of 100% and hundreds of units in operation. So, the superintendent was mistaken when he said “There are only two companies in the world who do elevators”. Now an educational facility, commercial property, medical facility, parking garage or housing unit can have a fully installed commercial quality elevator delivered when they want. Options are no longer limited.

If you are the least bit curious about our elevators and have a low to mid-rise project in mind, click the Fast Track button for a thumbnail budget number. If you want to explore more, schedule a Live Virtual Tour of our facility. We will show you how we manufacture a high-quality elevator that sets in four hours and starts up in a week.

A free elevator is a dream for many. Let’s face it, elevators are generally expensive if you want a good one. However, if you sharpen your pencil and your perspective you can find vertical transportation that provides enough savings to make even the highest quality elevator significantly less expensive.

But, to start the hunt for a free elevator you have to begin with a question. What in real terms makes up a commercial quality elevator that you find in any building project?

Well, in most basic terms it has to have an elevator car, rails for the car to ride up and down on and a hoistway the rails are attached to. That skeleton then has to have a heart. The heart is the conveyance system that makes the car raise and lower as well as open and close the doors at each floor. After that, to carry the analogy further, it needs skin. A great looking interior to the car with lights, buttons, hall calls and handrails. The hoistway can also be part of the skin in the form of a glass elevator and decorative finish or just a painted surface. That is what an elevator is in its essence.

There are two processes to accomplish the above:

The differences in the finished product of the two elevators are negligible (other than quality) as most of the component come from the very same supplier companies regardless of the process. Whether you are buying a modular elevator or have an elevator installed onsite each has the same pieces or the components have been through the same rigorous approval process. These two systems produce generally the same elevator.

So if the products are largely the same and roughly the same cost, how do you get one for free with modular, but not traditional?

The answer is found in the savings that you can obtain because of the modular nature of the MEM elevator. The chart below explains the process for both. The traditional elevator is significantly different by the nature of how they are installed. They take much longer to cobble together on your jobsite when they want. There is design and engineering, followed by permits and approvals, site prep and the foundation and inevitable changes. Finally when the pit is poured and construction begins, the traditional elevator company lurches into motion.

They order parts and make sure logistically all the pieces and tools are dumped on your site with you contractually responsible. Then they start the installation process most usually after power is turned on.

MEM (the gold row) on the other hand arrives when you want. It takes the design and engineering that we have partnered together on and begins manufacturing. By the time the pit is poured the fully installed elevator is ready to be set in place. That takes about four hours (no kidding). As unbelievable as it may seem, you have a fully installed elevator sitting onsite waiting for power. Then when you are ready to have a fully functioning elevator turned on, we make sure it is started up properly. It is really that simple.

The traditional or old-fashioned way of putting in an elevator is at the end of the construction process. This throttles the completion and this is not idle speculation.

A thesis and study put forward by the Penn State College of Engineering supports this contention. In an actual parking garage construction sequence of a five-story project it was found that the elevators took a crazy 58 days to complete. Also, they were the last trade to get started other than landscaping and parking lot striping. They were also the last trade to finish. Now imagine changing that number of 58 days to ten, putting the elevators in first and using it as a construction lift like we did at San Jose State.

The date the parking garage opens comes sooner as the job closes faster. This reduces overall costs in addition to other benefits. No more making space for storage of all of the parts and pieces. Big sections of projects are cordoned off for this purpose. That slows the project. Not to mention all the coming and going with a big carbon footprint. Also they are burning your electricity to install the elevator. MEM’s elevator comes pre-installed.

Lastly, with a modular elevator once power is on and adjustments are made, you can use it as a construction elevator.

So now sharpen your pencil and put a dollar sign beside each item listed below. How much is it worth that:

As you can see with the above list and a sharp pencil you can save ten of thousands of dollars or more by using MEM elevators on every low and mid-rise project. The general conditions alone can run tens of thousands per month. So when you balance the costs and savings, you can have a higher-quality elevator installed when you want for less.

Is the elevator really free? Nope, but the savings you will gain using an MEM elevator will often be more than your investment. Not to mention the faster occupancy rate that has as an additional benefit. I was once thanked for trimming months off a project putting more money in the investor’s pocket on a hotel project.

So summing it all up isn’t it time to at least consider a modular elevator for your next project? To get the ball rolling all you have to do is click the Fast Track button below. The form asks a few easy questions and then we will contact you with an obligation-free budget number. If you want to do a little more research join a Live Virtual Tour of our facility to see how we produce the highest quality commercial elevator that installs in hours. Just click that button to get on the schedule.

“Can I help you sir?” A confident voice asked from behind an impressive marble topped, dark oak wood podium. I had just flown to Los Angeles from the Midwest and couldn’t determine who would win the battle brewing inside of me. Am I more hungry than tired or the other way around? If there were a restaurant less than a block away my stomach would win. But, to crown one or the other impulse champion I had to know the lay of the land. There I stood at the concierge desk looking for the tie-breaker and answers.

I replied her inquiry by laying out my dilemma succinctly.

“All day on flights with just coffee, a stale chicken salad sandwich and airplane pretzels. Where’s the closest place to get a decent meal?”

Dutifully she pulled a map from her drawer and with a bold red pen and firm stroke circled the hotel on the map. All seemed to be going well and I anticipated what board of faire would be tickling my palate in just moments.

A green leafy salad or succulent steak, spicy shrimp tacos or 6 inch tall burger with bacon. It made no difference, all sounded delicious. Her confidence and willingness to help me had swayed the battle inside of me. Now the thought of chowing down on nearly anything she would suggest won the day. I could even feel my mouth water with anticipation.

She spun the map around with boldness and declared, “You are here.” My mind raced and I impulsively licked my lips as my eyes darted around the crude rendering with the bright red circle… But then all my thoughts and dreams of a delicious banquet were dashed in a moment with her saying, “Oh wait that’s not the hotel.”

She was very impressive and so were her surroundings. The hotel was very nice (nice enough for a concierge desk) and likewise her post and smart business attire exuded authority. She spoke with a certain assertiveness that gave me reason to trust her judgement. But, I had been had. She wasn’t even sure of where the hotel was on the map.

In one glance she could tell by my now stunned and bewildered look that I knew something was amiss. All of her assuredness seemed to evaporate before me as she apologized and admitted she just started that week and this was her first night by herself on the desk. She went on to further explain that she was not from the area, got turned around easily and never had even been to any of the area restaurants.

Unfortunately, that happens a lot where we fall pray to people that are trying their best and they have impressive back up, but their real experience allows only for guesses instead of answers.

We see this phenomenon often in the elevator business. A building owner, designer, architect or general contractor hungers for a solution to their elevator woes. And there are plenty of woes. Slow installation, arrogance, plugging up the work site with elevator components, delays and more delays.

Big elevator companies are not into solutions for vertical transportation. They focus on up selling maintenance agreements. Help is seemingly limited.

Modular elevators are a solution as the siren’s song beckons with the lure of an easy fix. But, then you find yourself lodged on the rocks of disappointment when the solution you were hoping for was only backed up by lack of experience, the approach of a neophyte and the smoke and mirrors of slick marketing and canned responses. No answers, only guesses.

What must be kept in mind is that elevators are complex and usually the largest moving object in any building. Then that complexity is compounded by various needs required from engineering to install. The result is that it takes true professionals and experience to make it all come together flawlessly and without disappointment.

The issue is not with the modular elevator concept, only a few in the modular elevator business. See, modular elevators are the solution to so many of the problems with traditional elevators, but only if they are backed up by experience. Modular elevators are the future and the present if done professionally and you get legitimate answers.

After all they are quite impressive and down right amazing and the results can be off the charts (recent project quotes from a GC). But to pull off the complexities and make the project go off without a hitch, it takes real experience. And that is what you will find in the leaders of the modular elevator industry at MEM.

MEM elevators are produced with more experience and higher skilled personnel than any other in the modular elevator industry. We provide quality, consistency and simplicity for every job we do. That means that you will find the experience refreshing and easy. We do all the heavy lifting with competent and professional project managers willing to answer any questions and guide the process from beginning to end.

What went wrong at the hotel was two-fold. I was taken in by the promise of food when I was hungry for answers. And the concierge put forth a façade of experience that encouraged me all the more. I then dreamed of the potential and the promise of a meal. Instead it was Cheetos and beef jerky for the main course and Peanut M&Ms for dessert.

I wanted a great meal, but instead got the vending machine.

When you are hungry for a solution to your elevator issues and you see what seems to be answers, think about the true experience of MEM and the value we bring in providing what you are really desiring. To get the ball rolling on the best solution for any low or mid-rise project, click the link below to receive a professional FAST TRACK quote. Or if you want to see how we produce a quality commercial elevator that installs in four hours schedule a LIVE VIRTUAL TOUR of our facility. Join the elevator revolution with real answers to elevator issues not guesses.

As a person that eats, drinks and sleeps marketing and modular elevators I try to determine the value of every part of our product. I constantly examine the value proposition of what we bring to the table. And I attempt to as closely as possible come up with an actual dollar sign for every element. But, beyond the real costs of steel and labor, value always includes intangibles like the value of experience.

What makes the value of experience so hard to quantify is that everyone thinks they have it. Therefore each believes they have the benefits associated with years in the elevator industry even when they don’t.

In other words, if you were to call any widget maker from Dixville Notch to Carlsbad and asked if they have the intangible of experience, inevitably the answer would be yes. This is regardless if they were a bank teller one week and selling modular elevators the next (true story for another time). The answer when asked would always be the same. We have tons of experience.

It begs the question is experience important at all? Or is knowing an industry intimately overrated? That of course depends on many factors, one being the complexity of the industry or product itself. The higher the complexity the more value there is in years of experience. So when you combine the demands of the elevator industry, modular building, construction, engineering, design and architecture, the higher the experience level the better.

Julius Caesar recognized the value of being long in the tooth and is credited in his work, Bello Civili with the wise words, “Ut est rerum omnium magister usus” or “Experience is the teacher of all things.” He believed the more experience you have, the wiser you will be.

He knew experience affords the ability to avoid the landmines and complete the objective with fewer problems even if it comes with complexity. When you go with less experience and cheaper costs you will be paying others to learn on your dime. Intuitively we all agree with Caesar placing such a high value on experience in that some will stretch it on resumés, bios or on their company website. So how can you tell who has or doesn’t have experience?

The issue becomes quantifying the immeasurable and then associating a dollar sign to that nebulous attribute. The first step of that process is a check list of what you should look for when dealing with an elevator company regarding a purchase. Here’s a good list of things to find out before you commit:

I am sure there are more items to look at than the listed above. But it is a very good starting point.

Now we know some criteria to look at, but how do you go about getting the information? After all it is very easy to purchase a company, change the logo and start spitting out product so beware. Especially in the online world it is very difficult to determine who are the professionals and who are the pretenders. To sort one from another keep the following in mind:

First, don’t be afraid to ask pointed questions. Your first conversation should be more about who they are than the product they are selling. Keep in mind to get you a price they will be asking about capacity, feet of travel and project location keeping the focus on you. Instead run through some of the bullet points above.

Second, probe deeper. As an example, if they say they have been in construction for a decade ask where what their job was. The more stuttering and stammering the deeper you should dive or just mark them off the list. They should be completely transparent about capabilities and experience.

Third, ask others. Trust me online reviews are not always accurate, but personal phone calls to people in the construction industry are much more reliable. Pick up the phone or email others.

Lastly, just remember your first contact should be more like a first date than a way to get pricing. This is because the project or building you are producing or own will be married for a long time to the elevator installed. An elevator’s lifecycle amazingly is about the average lifecycle of marriage 20+ years depending on all sorts of factors. So when you choose one company over another, you are marrying that elevator company to your building. Till death do they part.

For this reason try to know as much as possible before you say, “I do” and it is so much more than price!

The dollars and cents or value of experience is equally crucial and difficult to assess.

Just remember one mistake in our industry can be costly. One bad piece of information or one beam out of place and a project can be delayed for months. See our goal is for the elevator to be for the building owner like buying windows or doors. You call, get your price, tell your architect and GC and the elevator gets placed and turned on when you want it. Voila you have a complete commercial quality elevator installed in four hours (no kidding see some of our videos).

The hard work and details are on our side of the equation so you benefit from the ease of the product. But, what if due to lack of experience the pit is too shallow? The floor measurements are off? you were sent the wrong drawings? The engineering is inaccurate? Or the timeline is unrealistic?

Suddenly, the elevator is not so easy despite the slogans. You end up eating all the delays, additional construction costs and rework. What happens next are discussions, escalating to shouting matches and then potentially lawsuits. No one wins. Delays are costly and a modular elevator can be a great way to cut cost by eliminating delays and taking the elevator off the critical path, but only if you choose to work with an experienced company and experienced team.

To illustrate this, one common and simplistic example thrown around is a project that has a contract value of $50 million with a duration of three years. Doing the math that breaks down to a value per day of $45,662. That number may not be completely accurate to reality, but undeniably it shows what a delay of as little as one day can cost. Have I seen in my experience delays of days to weeks because of poor processes and lack of experience costing thousands? You bet.

I have dealt with a hydraulic jack falling from an elevator while on a crane, delays of deliveries due to inexperienced logistics coordination, elevator cabs dropped during the insertion process, floor measurements off by feet, warping of wooden cab components, drywall mold, poor wiring, overbooking production schedules and the list goes on and on. The primary cause of most of the issues that I have witnessed was a lack of experience.

That lack of experience ended up costing the owner of the project dearly. Experience is worth the additional investment. Because as stated above days means money and mean a lot of it. Paying more for experience upfront could mean saving thousands. A fair evaluation of the real dollars of experience is difficult. But, just ask yourself how many days have you lost due to no experience regarding an elevator? Look at the list above of problems I have seen and the days to weeks of waste they have created. The outcome was thousands wasted. Not to mention the inflated cost of aspirin.

The good news is that none of the above examples happened at Modular Elevator Manufacturing. As a matter of fact, one of the reasons I am at MEM is because of their stellar record regarding experience, quality, honesty, superior engineering and reputation in the construction industry. I got tired of explaining failures due to lack of experience.

So, if you are tired of the added expense that lack of experience can cost, then I encourage you to give MEM elevator a try. They are the best option for any low to mid-rise project. We are true professionals in the elevator and construction industries. Many companies claim the intangibles we all desire, but few deliver. MEM delivers.

If you would like to see first hand the production facility and experience our openness, you can now take a LIVE VIRTUAL TOUR by clicking the button below and signing up. We will answer any and all of your questions. If you would like to get a thumbnail number for an upcoming project just request a Fast Track Quote.

When it comes to the green movement, it seems everyone has an opinion. Seemingly in play are the validity of claims, the science, who is at fault and of course funding. You probably will be grateful to know I am not going to dwell on any of that in this blog post. Instead, I am going to focus on a real solution we provide when it comes to construction projects. Specifically, how we can help to make construction more eco-friendly by providing a greener solution.

This is not going to be a screed. You can get all you want of that in other forums (there are plenty). This will be an honest look at real solutions or our deeds not words. See, there are two distinct camps when it comes to building greener. The true believers that are keenly aware of environmental issues and sincerely seek out greener alternatives. Then there is a more cynical bunch where “green” is more of a buzz word. It is viewed as an inconvenience, extra cost and larger headache that the builder is required to contend with.

Regardless of which camp you fall into, this post will show MEM as a better solution overall. Regardless of your opinion on sustainability, or the environment we at MEM are still and have always been the best the solution for any low or mid-rise building.

You can be of differing philosophies at the polar opposites of the discussion on climate or environment and still reach the conclusion that our ideas and innovation are needed. We are not necessarily concerned with how you arrived at building greener with MEM we just want to welcome you aboard.

Also, I am not going to dwell on sophistry or window dressing that you see so much of. Let’s face it, it is far too easy to wave around marketing pieces and propped up green accreditation. I grow weary of Neville Chamberlin like pronouncements of true change in our time that are worthless in real terms. Especially, when you consider nothing in the old elevator industry has changed for years. That is until the advent of the revolutionary modular elevator by MEM.

So here are a couple of real ways modular is a greener solution and why we are a better solution overall.

This is huge! Largely due to the fact that power usage for a standard 2-stop elevator with moderate use equals only $40 to $50 dollars a month or less. You can trim that consumption number a bit with LEDs and settings, but the real environmental savings comes during the installation. This is where true innovation can have an impact.

See, believe it or not the way elevators have been installed has not changed since the Civil War. Our Civil War in the US, over 160 years ago! In 1859 even prior the advent of passenger elevators a hoistway or shaft was built in the Cooper Union Foundation Building anticipating vertical transportation. In the lumbering brontosaurus that is the elevator industry that model has not changed since. That sounds crazy but its true.

We see it when we drive by a construction site. A concrete block or cement structure is built (usually first) standing there like the obelisk to ignorance it is. This clunky, old-fashioned way of building the hoistway first is an environmental train wreck in many ways.

First, the environment suffers every time a team of bricklayers drives their diesel doolies to the construction site everyday for weeks on end erecting the scaffolding, forms and the hoistway structure. Not to mention the production of the product itself and waste involved in mixing all that cement and producing block.

Despite inroads, concrete, cement and block is the least recyclable material recycled in construction. However, our revolutionary process produces hoistways built out of steel and are therefore greener. This is because steel is the most recycled material in the world, with about 98 percent of all structural steel avoiding the landfill.

Concrete is another matter completely. According to the Cement Sustainability Initiative “Recycling concrete reduces natural resource exploitation and associated transportation costs, and reduces waste landfill. However, it has little impact on reducing greenhouse gas emissions as most emissions occur when cement is made, and cement alone cannot be recycled.” (emphasis added). In other words if recycling and reducing greenhouse gasses is the measure or your desire. Concrete gets a failing grade.

Using steel overall or recycled steel on the other hand impacts greenhouse gasses significantly. It takes 75 percent less energy to make recycled steel than steel produced from its raw material, iron ore. The green solution is a steel hoistway. If you truly want to make a difference in deeds not words, dump as much concrete and block you can out of your plans and go with steel.

But even more impressive is the possible reuse of the structure itself. A modular elevator can literally be picked up and moved.

Although this does not happen often as the lifecycle of a modular elevator is the same or even longer than a conventional elevator. Repurposing the steel shaft is possible. Even the EPA recognizes reuse as an important component of sustainability. If you cannot use the entire structure it can be cut to length for any number or reuse projects or it can be more easily recycled.

Concrete is severely limited in reuse possibilities, recycling it has no effect on reducing greenhouse gasses and cement cannot even be recycled. To fabricate a steel hoistway it takes less energy overall and less time. It only makes sense to use a modular elevator for any low or mid-rise building.

Another twist on reuse is…pre-use. A modular elevator installs so quickly that it can be used as the construction elevator. Imagine all the carbon it takes to haul in, set up and operate a temporary elevator. MEM elevators can be used instead and then switched to permanent passenger use when ready. This makes sense whether you are looking for a green alternative or not.

We covered the hoistway regarding steel versus concrete and it is a pretty impressive win for modular, but there is more. The actual old method of installation of the elevator equipment is another black mark on the record of the out of date elevator industry. Remember that building in 1859? The Cooper Foundation? Here’s why it matters.

This may shock some of you but, everything that is in an elevator hoistway has to be installed by taking the item through the elevator doors in the building and into the shaft. Everything! Rails to cab, wiring to doors. I tell this to people outside of the construction industry and they look at me like I have three heads. It is that unbelievable. But, again if your model for efficiency is pre-Civil War what do you expect?

So with a traditional elevator a crew drives to and from the site as needed for weeks to hand carry all the bit and pieces of the elevator into the shaft. Inside they screw, cobble, bolt and coerce together all the pieces. As they come and go others come and go too. Parts, components and tools are delivered. And don’t forget lunch breaks. All this travel burns fuel by the gallons. Spewing exhaust to no end in the air.

On the other hand a modular unit is completely assembled in the factory. The hoistway is manufactured and then all of the components are placed inside.

Efficiency is what we do and as a result we have a better product delivered faster that eats up less fossil fuels and produces less carbon in the process. Win for everyone. Our installation takes place at a factory with careful inspection and care. There is only one trip with a crane to the site to set the elevator in place. A process that takes four hours or less. Again modular is the greener solution.

In this post I only covered the hoistway and the installation but, there is more…much, much more. The reason is that modular elevators are factory built and have tons of opportunities to save energy, reduce waste and increase recycling.

To you cynics out there that are not believers in the green movement, remember that we revolutionize construction by moving the elevator to the front of the building process. That means your building will be completed faster. Greener for the environment whether you want it or not but greener for your pocketbook in time saved, efficiency and quality.

But the “green” doesn’t end with the hoistway and installation. Here’s a list of other benefits to modular elevators:

Why are the old elevator companies lagging so far behind the curve regarding green issues? In a nutshell, because they are not elevator manufacturers. They are elevator maintenance companies. Their goal is not to innovate or find better ways, their goal is to sell maintenance deals.

With MEM we manufacture elevators and are constantly pushing the industry in new ways by making improvements and seeking innovation. It is what we do and you can see that in our vision – MEM’s Vision: We believe in challenging the status quo…in revolutionizing the “elevator process”. We don’t just think outside the box…we think BEYOND the box.

Lastly, you have to ask yourself, “Is going green really important?” If it is then you have no real choice, modular elevators are a must for any project low or mid-rise project. If you consider yourself green, but do not at least look into MEM elevators then how committed are you really? Remember deeds not words.

For the cynics ask yourself, “For the same general investment would you be impressed with a truly green product that installs in four hours and saves you countless headaches, time and resources?” If the answer is yes (which it will be), then modular again is the best alternative.

Modular elevators are a green solution for everyone. For that reason alone is time to join the MEM revolution. Click the button below for a Fast Track quote on a project you have in mind or set up a Live Virtual Tour of our facility.

Seeing is believing. Now you can see our process first hand live. Just request a virtual tour of our production facility. When we discuss commercial quality modular elevators or write about them in blog posts, it can be hard to visualize what we are talking about. To help, you can now schedule a virtual tour of our facility and see how we are revolutionizing the elevator process.

These are one-on-one, live conversations with our national director of sales, national territory director or sales personnel. They will virtually walk you through the factory and answer any questions you may have.

To schedule your tour all you need to do is click the Fast Track button below. Then check the box for a virtual tour and fill in “required” contact information. If there is no specific project name or project city just enter “none”. We will contact you to schedule the tour at your convenience.

By opening up our process we are being transparent in what we do and how we are revolutionizing the elevator industry for the better. In that way we demonstrate how we fulfill our Vision, Mission and Core Values daily.

MEM’s Vision:

We believe in challenging the status quo…in revolutionizing the “elevator process”. We don’t just think outside the box…we think BEYOND the box.

MEM’s Mission:

To revolutionize and simplify our customer’s experiences with the elevator process. And to build the best engineered, highest quality modular elevator on the market while maintaining our values of consistency, quality and simplicity.

MEM’s Core Values: Innovation, Integrity, Quality, Consistency, Simplicity

So sign up today! Request a virtual tour by clicking the Fast Track button below and fill out the required information. See how we can produce a high-quality commercial elevator that sets in four hours and starts up in just a week. The revolution has begun.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.