Dirty Little Elevator Secrets II – Hospitality Needs the Best Lead Time – Usually, I try to begin a post with a soft approach. It pulls the reader in and makes for a better read. But there is no soft-peddling or easing into this one. Plainly put the MEM Elevator System has the best elevator lead time in the construction industry today. It really is that simple. Once all the preliminary work is complete we can deliver a fully installed, ready to start up, commercial quality elevator in less than 6 months. Crunching that lead time is exactly what the hospitality industry needs (See our latest project at a Disney Resort). With all that in mind we are cluing you in to Dirty Little Elevator Secrets.

But beyond delivering a fully installed elevator when you need it, when it comes to hotels all your specific requirements can be addressed with the MEM Elevator System. Ultimately, for low and mid-rise projects there is no better option that has the reliability and flexibility you need. This includes all building types including modular, storage containers, stick-built, reinforced concrete or any other type of construction.

We can produce elevator cabs to any specs you wish and glass elevators are easy, for us. The units can be for new construction or retrofit projects. They can be on the exterior of the building or on the interior. Placement doesn’t matter. MEM can provide exactly what you need.

Here’s a dirty little elevator secret – With our process you get your elevator when you need it. A fully-installed high-quality commercial elevator can be placed on your site in less than four hours.

It is a real simple process. We know precisely how long the manufacturing process takes from start to finish. You tell us when you would like the unit or units delivered and we back the start of manufacturing to meet your schedule. That easy.

You keep us updated regarding any changes so there are no surprises. When the start date rolls around we manufacture the hoistway and wrap it in the appropriate amount of drywall per code. Then the elevator rails and entrances are installed. Simultaneously, the cab is being built to your specification. All the wiring is being completed. Then the cab is inserted, final prep is done and your elevator is delivered and ready for start up and inspection.

It is more than time to end all the headaches you face with the elevator portion of your project. There is no reason it has to be so complex and filled with so many problems and delays. We have started a revolution with our design and process so join the revolution.

Click the button for a Fast Track or schedule a LIVE VIRTUAL TOUR.

We Are More Than Modular – With the big win at the World of Modular conference where we won two trophies, it is easy to think our MEM Elevator System is only for modular construction projects. Yes, the first place Award of Distinction was for a park concession area that was built totally with shipping containers. And the runner up Award of Distinction was for a traditional modular build. But don’t let that fool you into thinking that Modular Elevator Manufacturing creates its award winning elevator solutions for just the modular industry.

Far from it. All sectors of the construction industry can benefit from the easiest, fastest and most cost-effective commercial quality elevator solution. It is for everyone. Our projects can include retrofit elevator installation to new construction.

One of our recent retrofit projects was placed on the exterior of a production facility. It went up so quick that the construction elevator was taken down with the benefit of the savings going to the owners. The elevator could have just as easily been placed in the interior of the build by cutting a hole in the roof and lowered into place.

Another application that is not modular is for parking garages. The MEM Elevator System can be placed along side the structure for a fast and easy way to meet code and provide vertical transportation.

Traditional construction methods are employed in a wide range of vertical markets and we can help meet those needs as well. Hospitality, commercial spaces, schools, and medical facilities all have used our solution with great success. You can see some of them below and here in our gallery.

The reason for its popularity and that it has largely found market acceptance is the MEM Elevator System has significant benefits over traditional elevator installation:

So the bottom line is that we are grateful for the recognition. It is confirmed, we are the leaders of the modular elevator revolution and our recent awards prove as much. However, what means more to us is that we can provide a much needed solution to vertical transportation woes.

If you want to join us in this better way, regardless of your project, contact us. We can provide a solution for all low and mid-rise applications. To find out more click the button below and schedule a live virtual tour of our facility. If you have a project in mind, start the process by requesting a Fast Track Quote.

Non-proprietary parts matter. However, often times non-proprietary parts are over looked, not considered or just not understood. So, let’s start from the beginning. What’s the definition of non-proprietary elevator parts and how can they solve problems regarding your elevator choice.

Generally, proprietary elevator parts are components produced, marketed and controlled under exclusive legal rights of the manufacturer. The manufacturer has no obligation to share any information about the part or component, how it functions, how it operates, how it can be repaired or used to adjust or improve the overall functioning of an elevator unless it is contractually obligated to do so.

Non-proprietary on the other hand, means there are no restrictions to the use or what company can repair or improve the functionality of the elevator.

Well that was a mouthful. The definition can be reduced to a more simple, proprietary elevator parts are ones that only the manufacturer can repair or use in a repair or maintenance of an elevator. Non-proprietary opens the door to any qualified and licensed elevator professional.

An even more concise characterization is, proprietary bad; non-proprietary good.

But why? Why are proprietary parts to be avoided when looking at elevator purchases.

There are limited arguments against choosing an elevator that has non-proprietary parts over proprietary. When non-proprietary options were first available, there was a short time that they were considered inferior due to their recent emergence.

That thinking is no longer a concern. There is a decades long track record now that shows reliability and durability for non-proprietary components. Keep in mind that all elevator components and elevator operations are subject to elevator codes, inspections, and parts must pass rigorous testing before they would ever be allowed in an elevator.

Also, much of the functionality that proprietary elevators could boast of is now available with non-proprietary units.

Too many times we receive calls from individuals that are dissatisfied with their current maintenance supplier. They are sometimes unresponsive, operate at their own pace with little concern for the end user or the building owner and often lack availability of parts or tools with many on back order. With proprietary parts you lose the ability to find solutions to the problems you are facing.

This was illustrated in a recent article regarding elevator repair delays. A lack of parts was the cause for denying people mobility and access. You can help shorten that time of repair if you chose for your next project an elevator without proprietary parts. If you want to know more about us, just click one of the buttons below. We would love to talk to you about your next elevator project.

You should care – Elevator parts are not all equal…but they are. Years ago there used to be a commercial that had the catch phrase “Parts is parts”. They were talking about chicken nuggets and not vertical transportation and their facetious point was parts are not all equal. There are better and worse pieces of the chicken to use in the production of a nugget.

In the home or commercial elevator industry that knife cuts both ways and a bit hard to explain. First, it is true there are differences company to company in components. But second, those differences are superficial at best and for a purpose. So the parts are not all equal but… still equal??? How does that work?

That doesn’t seem to make sense so let me explain this weird dichotomy by stating the following. Factually, most companies purchase the bulk of their components from the same group of independent companies. As a result an elevator, home or commercial, is filled with dozens of components and pieces that come from those various companies from around the world. The difference is largely relegated to different nameplates and logos being etched or painted on the components themselves and that is about it.

This gives the illusion that they are all coming from the elevator company you are buying from. Generally that is not true. As a result when you step into an elevator car most often very little of what you see or that makes it go up and down, comes from the name on the control panel. And in all likelihood the bulk of those parts are found in every other elevator you ride regardless of the company.

Also, the vertical transportation industry, for good reason, is highly regulated. Elevators in the United States make 18 billion passenger trips per year according to the National Elevator Industry Inc. For that reason alone it is very important that all parts must meet high standards. You just can’t put anything you want in the elevator as a component. They must be test and approved for quality and durability.

Alright, if only a handful of companies produce most of elevator components and all parts meet the same rigorous standards, how can they possibly be different? Well before I get to that I want you to know that I am not wearing a tinfoil hat. I believe that we did go to the moon, Elvis is dead and aliens had no part in building the pyramids. So what I am about to say is not a crazy conspiracy.

Here, goes. The big commercial elevator companies make the bulk of their profits in maintenance and not selling you an elevator. Shocked? They realized pretty early on that if any certified elevator contractor could provide maintenance, they could lose customers and money. People would simply shop around and find the lowest price for service.

The solution was two-fold. First, sell elevators that require the most expensive maintenance agreements regardless of the purpose. Second, place in those elevators components from manufacturers that will require special tools, passwords or programs to maintain the elevator.

If you combine those two principles with a confiscatory maintenance agreement you have a lock on maintenance income for that unit for decades. And there is really no way for the building owner to extricate themselves from the long-term costs.

So, despite elevator components largely being the same, parts are not all equal. This is by design and for a specific purpose that has nothing to do with the elevator ride or functionality.

Unfortunately, when asked, “What can I do?” the responses are limited. This is especially if you already have an elevator in place. It is not practical nor cost effective to replace the proprietary parts that force you into the long-term contract. It’s like the old adage, you pay for some mistakes forever. But learning from those mistakes is important as well as spread the word that you can make upfront decisions next time that will save you from the headaches and costs associated with choosing the wrong company.

The word to commit to memory is non-proprietary. Non-proprietary parts and components are simply those that any elevator technician can work on. They are not better or worse they are just accessible for maintenance from any company. You can even use the big elevator companies if you wish. It just opens the door to anyone to repair or maintain the elevator. So always, always, always have an elevator installed with non-proprietary parts.

Finally if you have any questions regarding what proprietary parts and components can mean to your elevator project please contact us. At TL Shield and MEM we pride ourselves on giving honest answers to your questions about elevators, home or commercial.

All you have to do is click one of the buttons below to get started.

Modular Elevator Innovation – There are a few inventions that become moments in history that change everything. The Wright brother’s first flight, Guttenberg’s printing press and Edison’s light bulb are at the top of the list. But one moment rarely considered is the time Elias Otis cut a rope on a suspended the elevator at the 1853 World’s Fair. On that fateful day when the cable was severed the elevator did not fall due to his unique braking system. The elevator became safe and the world was able to build up creating skyscrapers and a new city lifestyle beyond four-stories.

However, since that great leap ahead, the elevator has remained largely stagnant in how it is installed in a building.

Designers, architects and engineers have been trapped into placing a tower in the midst of the project and after nearly everything is finished, the project is turned over to the elevator mechanic. They come and go as they will and one piece at a time the elevator is built from scratch from crates of parts inside the hoistway.

That laborious, inefficient process is carried out anytime a multi-story project is built. This slows completion, wastes resources and can greatly expand the time that it takes to allow occupancy. But this building mess can be cleaned up through the use of a modular elevator. The modular elevator innovation changes everything.

This innovation is not new. After the passage of the Americans with Disability Act a group got together and thought through the conundrum of providing vertical transportation quickly at a cost that would allow more access. Their idea included building a steel hoistway that could be placed in hours with all of the elevator components already installed inside. The concept was perfect, but execution was lacking.

From an elevator installer’s perspective significant improvements could be made to reduce time, increase quality and diminishing inefficiencies even more. T.L Shield and Associates president, Tom Shield took up the challenge and the birth of the first true and practical modular elevator was developed. Modular Elevator Manufacturing (MEM) was founded and mass factory production of the MEM Elevator System began. Tom Shield said about the process, “We never set out to create an elevator revolution, we just wanted to solve problems to vertical transportation for builders and installers. We feel we have accomplished that goal.”

“We never set out to create an elevator revolution, we just wanted to solve problems…”

Tom Shield – MEM President

As the market expanded additional innovation has been tested and accepted leading to the high-quality alternative to conventional elevators we have today. Shield said, “It has been a long road to market acceptance, but nationwide people are seeing the modular elevator as a solution to many of their problems and we continue to project significant growth.”

The stead increase in market share continues as architects, designers, project managers and building owners see the value in controlling their projects, cutting general construction costs and having occupancy faster than with old-fashioned traditional elevator installation.

As you can see Modular Elevator Innovation has led to an alternative that has been accepted and should be considered prior to any multilevel project. To reduce time, costs and headaches, we have a solution for your project woes regarding the elevator.

The modular elevator is not just a quick tip up for the outside of a building. It can be banked with other elevators and fitted with any design. Our commercial quality elevators can be used in retrofit or new construction just like traditional elevators, they just don’t come with the same baggage.

So if you would like to explore more, you can schedule a live virtual online tour and see first hand how we produce our modular elevators. You are also welcome to visit us in person as well. Just let us know when you are available.

Lastly, if you have a project in mind and would like to explore your total costs and benefits regarding our modular elevator complete a request for a Fast Track Quote. In about 24 hours, we will provide you with a thumbnail quote and get your project started. Just click one of the links below.

Modular Elevator Footprint – Often times when comparing the revolutionary MEM Modular Elevator System to traditional elevators the modular elevator footprint size comes up as an obstacle. This is especially true regarding interior placement. In this blog post we compare how much space is taken up in an apples to apples comparison.

There is a lot of confusion over exactly how much space the hoistway will ultimately require. To clear this up we went to our valued California partner TLShield for answers.

Senior Sales Executive, Craig Braund is a leader in the elevator and construction industry. He is known for using clear communication to solve problems for a variety of builders and architects. He took the time to examine the statement and question:

A modular elevator footprint takes up more space than a conventional elevator. Fact or fiction?

Coming to a conclusion on this question can be important. Especially to builders, architects and contractors when they consider switching to a modular elevator in the interior of a building. They like the fact that the modular elevator is off the critical path. It also saves time on the job and ultimately is a cost savings. However, switching from a conventional elevator, already designed in the project, to a modular elevator can be a hard decision to make. This is especially true when they are presented with the inside pit dimensions. This is because they believe they will have to totally redesign the building space for the elevator by a foot on each side to fit the MEM Modular Elevator System in.

But below, you can see that isn’t the case.

A typical 3500G (Gurney) conventional elevator has an inside pit / hoistway dimension of 6’-11” x 8’-6”

The MEM Modular Elevator System HW-2 3500G (Gurney) has an inside pit dimension of 7’-10 1/4” x 9’-6″

But is the required building space really larger? Here’s where it gets interesting.

The hoistway walls on a conventional elevator are typically between 7” and 8”. So the actual overall outside dimension (using 7” walls) of the elevator and hoistway is 8’-1” x 9’-8″.

A HW-2 3500G MEM Elevator with a 2-hr fire rating has a overall outside dimension (outside steel plus 2 1/2”) of the elevator and hoistway of 7’-9” x 9’-4 3/4″.

So in reality, an interior MEM Elevator actually takes up less building space. When the hoistway walls are utilized as building walls as done typically. The good news? No major redesign is necessary at all.

Therefore the answer to the “fact or fiction” question is… fiction. The modular elevator footprint is actually smaller.

If you have been holding back on considering the MEM Modular Elevator System because you thought interior placement was a problem with the modular elevator footprint size, we hope you reconsider.

As you can see we are a great option. We can be your solution to taking the elevator off the critical path. Additionally we can provide you with time and cost savings. To explore more you can click the button below. Sign up for a LIVE VIRTUAL TOUR of our facility where we show you how we produce this revolutionary product. If you have a current project and would like to explore more with pricing click the Fast Track Quote button.

We would be glad to have a conversation and help you with a solution to your vertical transportation needs.

Elevator Forum Produces Results. For those of you who are new to Modular Elevator Manufacturing (MEM) we are an elevator manufacturer. But not your typical company. We are trying to foster a revolution in an old industry that has not changed in 150 years. To help in that effort, we have sponsored a poll about the elevator industry so people in the construction industry can let us know the challenges they face when an elevator is part of their project. You can still participate by clicking the button below. It is just five short questions.

We then take those results and further define the issues you face by holding an open forum and clarifying the issues. The next step is then to make an honest effort to reform an industry in desperate need for a revolution. We will make changes to how we do things but also publish important information that you can use across the industry regardless of who you choose for your vertical transportation needs.

One vertical industry at a time we will be offering these opportunities for change. Our first was a success with the parking garage industry. The results of the forum were not surprising, but interesting to say the least.

First, when we said we were having a free and open discussion, we expected people to strain to participate with a largely one-sided conversation. Nothing could be further from the truth. We went through each of the poll questions and listened. To our surprise there was a lot to hear.

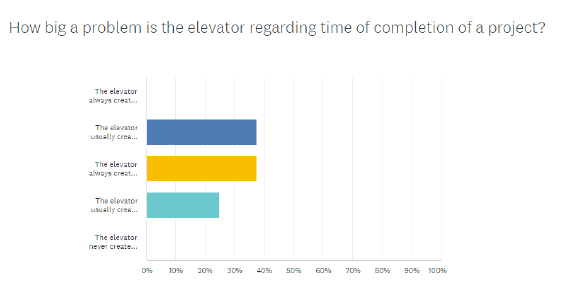

For instance when we asked specifically about time of completion and the elevator’s impact we were shocked at the candor.

The elevator installation “Usually creates major delays” to “Usually creates some delays”.

This is a major pain-point for the builder and the elevator industry.

Discussing that single issue propelled a discussion that elevator manufacturers need to hear more about. It seems that the overriding thought from builders across the construction industry is that the elevator installer are actually looking for ways to leave the jobsite. That leaves timetables for completion unpredictable.

It turns out that elevator mechanics once they get on the site are often looking for ways to get back off the site as fast as they can. We know many of the major reasons that occurs. An emergency somewhere else is a good reason if true. But they become more difficult to swallow after that and seem more like excuses. Examples such as it is too hot or too cold in the hoistway or shaft has led to a running joke in the elevator business (especially in colder climates), the technician watches the thermometer more than the time clock. If it drops below 55 degrees, time to go home.

The elevator company will sometimes come clean with an acknowledgement they double booked or they are trying to finish up another job somewhere else.

You will hear that they don’t have all the parts they need.

But a new reason to abandon the jobsite from wayward elevator mechanics came to light as well. I had never heard this one before. It is too dusty in the shaft. That was a new one on me.

Overall, because of a lack of trust in the industry as a whole or lack of trust in an individual company, builders are just not buying it.

This discussion led to the most damning indictment of the whole conversation. The elevator company is just looking for reasons to leave the site and they are not team players.

“The elevator industry generally takes the opinion, too bad.”

The feeling of the group in the forum was that everyone in the construction trade from plumbers to electricians have failings; they double book, they fall short in deadlines and have cost overruns. But after its all said and done they do their best to finish the job on time as promised. The other trades think through the problem or through the difficulty and work with the rest of the team to pull it all together.

That may or may not be an accurate picture, but it is the perception. The elevator industry generally takes the opinion, too bad. That has to stop.

I always hate using football as an analogy, but it fits here. When I was playing I could miss a tackle or a block, miss a read or blow an assignment, but if I did everything I could for the team to be a success it was forgotten (usually after 100 down and ups). It is true that I might have to ride the pine, for a game or miss a first-half, but all was forgiven. I was welcomed back. No one was never endanger of being kick off the team for a mistake.

The elevator industry has a habit of acting like they can do what they want, when they want and there is nothing that can be done. Mistakes are common and often and little effort is made to make them right. If this keeps up they are going to find themselves kicked of the team.

But the time for change is coming. A revolution is starting. It may begin small, but we are hoping to detect the pain-point through the polling and forums and then lead to find solutions. It is going to take honest communication throughout the construction industry from architects to elevator maintenance companies, but change is on the way.

And this leads to the final point where we usually turn all this information into a pitch for our revolutionary product. Yes, you can click the links below for more information if you want, but that is not the purpose.

If you want to be a part of the elevator revolution and improve the way the elevator is placed, designed, started up and maintained we invite you to be a part of the solution. You can start by taking the simple five question poll. It will only take a couple minutes. You can then contact us and ask to be included on future phone conferences. We will discuss the poll in its entirety and you can have a hand in influencing the future of the elevator industry.

If you want more information about the MEM Elevator System just click the link below.

New York elevator set over the holidays. While most businesses slow down between the last couple weeks of December and January 1, MEM’s schedule picks up. That slow period for most (especially schools) is the perfect time to install a complete elevator in less than four hours with the MEM system. Because they install so quickly there are minimal interruptions that you will find with traditional elevators.

A great example is a project we just set in New York. The Ateres Girls School was a perfect fit for us. The MEM system for the school is an above-ground hydraulic unit with a 25000lb. capacity and 16′ travel distance. It went in easily and smoothly.

That not only speaks to the product and our production team, but also the professionals at Nadler Modular that led the project. They made sure everything was ready and therefore the project went off without a hitch.

A modular project is not a requirement. Even with the elevator placed on the exterior of the building, that is not a always necessary for our elevators. MEM elevators can be placed in any type of construction project. And be placed on the exterior or interior. If you are looking for a vertical transportation solution for any low or mid-rise application we have what you need.

To make MEM a part of your next project just click the link to find out more or get a FAST TRACK QUOTE.

Elevator Winterization – Oh the weather outside is frightful…is your elevator ready to let it snow, let it snow, let it snow? As a chill fills the air in most of the US and Canada, it is a good question. Is your elevator ready for cold temps and inclement weather? This blog has always been about all things elevator including how to take care of them and keep them operating at peak performance. As a result, cold seasonal temps should be addressed. So consider giving your building the holiday gift of elevator winterization.

The holiday season is the perfect time to consider some of the following items. Some of the tips may be part of routine maintenance or you might be Florida, however these are things to consider regardless:

The above is just a short list you can talk over with your elevator maintenance company. If they are not responsive, give you grief or want to charge more for a simple winterization check up…you got the wrong company. Follow through on firing them as soon as you can.

You are responsible for the safe operation of your elevator and the above list will help, but you have to have a willing partner. It is always a good idea to line up maintenance now than dealing with someone stuck, especially when it is cold outside. Be proactive so your elevator can give you years of reliable service. Remember as long as you love your elevator so, you can say let it snow, let it snow, let it snow. Happy Holidays from Modular Elevator Manufacturing!

Not going to say much here, but lots of the above steps can be interrupted by purchasing an elevator that has proprietary parts and components or use proprietary tools. Never, let me repeat, never purchase an elevator with proprietary parts and tools. It is a scam and a rip off to increase your costs and the elevator company’s profits in the long run. Secondarily, never purchase a building with an elevator with proprietary parts. It is largely an unseen future expense that will drive up costs for maintenance agreements.

We at MEM never use proprietary parts and tools. Contact us to find out the reasons why. You can also get a Fast Track Quote by clicking the link below. Lastly, if you are interest in the least, set up a live virtual tour of our facility. You can ask any question you want and find out for your self how we are taking you higher with high-quality commercial elevators.

Elevator 101 is about the basics. See, being around elevators all the time can warp your perspective. You begin to think that everyone has a pretty high base knowledge of elevators and elevator lingo. We tend to forget that most people’s knowledge of elevators in the construction industry is limited to, “They are a pain in the rear end”. So, every once in a while it is a good idea to review what the basic terms mean. Reviewing this info is especially needed if you are going to be chatting with people in the elevator business about a specific project.

Overall there is too much jargon. Like talking to a doctor or lawyer, elevator people sometimes skip over things that are basic to them, but may confuse folks not immersed in the field. The intricacies of brain surgery or the meaning of habeas corpus (I think its a city in Texas), can easily pass us by and so can terms regarding elevators. We hope this will help.

So here is a list of basic terms that you should review, or bookmark before you talk with an elevator consultant, elevator sales person or even an elevator mechanic.

That above list is a good staring point. However, if you ever have a question feel free to call us whether you have the intention of buying a modular elevator or not. As geeky and weird as it sounds, we like talking about elevators.

Below is a handy diagram, a chart based on travel distance and some links.

Additionally if you want to know more about the modes of conveyance. Just click here for a full explanation. You can also click here for information on hydraulic units. You can also look at the dozens of articles we have available on our blog.

If you would like to know a bit about pricing for a project just click the button below to get a Fast Track Quote. But if you really want to know more about elevators, schedule a live, virtual tour of our factory. It is open to anyone with questions about elevators. We love showing off!

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.