“The elevator holds everything up!” that is a common complaint among those in the modular building industry. Modular companies are growing by leaps and bounds. However, finding a way to incorporate vertical transportation quickly and smoothly was always a sticking point.

It is true that modular building is the future. It just makes sense as it means a high-quality project completed in a greener and safer way. But one of the biggest selling points with modular is the speed in which the project can be completed. Typically when you place traditional construction on a timeline there are gaps. After the permits and financing is set, the ground has to be prepped. Then the foundation is poured and infrastructure for the building brought in. Months tick by.

Meanwhile, despite the project being totally ready to go, the building makes it no further. There it sits as plans on a drawing board until the site is completely ready. Modular takes all of the waiting out of the process. The building can begin as the site is being prepped. In that way when the location is ready, modular units are ready to be immediately swung into place. It is estimated that modular building can reduce time significantly. This is because construction of the modular components can occur simultaneously with the site and foundation work. This means projects can be completed 30% to 50% sooner than traditional construction.

The modular process does speed things up incredibly fast, but there has been a huge fly in the ointment. The elevator. Despite advances in modular building, the elevator was mired in old-fashioned construction practices. Or the companies that built modular elevators were so low in quality that headaches outweighed any benefits of speed. Dangerous product were even being distributed. A new nationwide solution had to be created for the modular industry.

The results is MEM and we are increasing distribution to the whole nation. Now from New York to California and Florida to Alaska there is a true quality solution. A solution that is reliable and fast to set and start up.

As an example, realizing the need for speed and quality, MEM was called on a multi-family housing unit. It was completed on time and on budget with quality elevators. The builder’s experience had dictated that a conventional elevator NEVER gets the elevator done on time. But, they called MEM and got a taste of what we can do. Now they will never go back to any other way.

Soon modular builders will start using MEM nationwide and the complaint about the elevator holding up the project will disappear. It will be just like the solution we provided above and there will be no turning back from the quality and speed we provide.

If you have a project in mind and you are ready to try out a modular elevator, click the link below and we can give you budget numbers in a day. To fill out the Fast Track quote we just need a little simple information to get you started on a fast – safe – quality solution.

Trade Show Success! – The annual CASH (Coalition for Adequate School Housing) Conference was a huge success as it is every year. It always amazes the MEM team at how each year it grows. With that growth we get to meet new people and discuss vertical transportation for schools. CASH gives us a unique opportunity to meet not only the architects and superintendents, but people that use our elevators. From them we get to see how access is improved.

At our booth we hear the stories of replacing rusted out ramps or stairs and rickety old wheelchair lifts. For those in need and this gives us a boost of confidence and pride. Also, we are told of how we have helped save millions in additional costs. With our solution and quality elevators for new construction adding floors saves money instead of sprawling campuses.

This is not to mention the time and resources saved on the job-site when our modular elevator is chosen. We find being the best vertical transportation alternative very satisfying. We will continue to attend CASH Conferences in the future and share with our friends how we love to help.

As for those that do not see value in organizations like CASH. We feel it is their loss by turning their back on the needed mission. Some don’t attend so they can dodge questions about the safety of their product. Or maybe simply they don’t support California schools. We may never know. But one thing we do know is that MEM and TL Shield fully supports CASH and its mission. We look forward to a long relationship with them and the schools of California.

If you were not at the conference and part of the trade show success, but have a project in mind that we could be a part of, just click the button below for a Fast Track budget number. We would love to get started. Of course we will provide formal numbers or bid proposals at your request. Remember that MEM is the best option for any mid to low-rise building, especially California schools.

When you are the leader in an industry it is an obligation to educate, inform and instruct. When it comes to benefits and solutions of the products you create you must tell others. For that reason, Modular Elevator Manufacturing has launched a brand new website, modularelevator.net.

The purpose of the website is to clearly demonstrate modular elevators as the best alternative for low and mid-rise project. It is a new, easy to navigate way to increase awareness and information sharing about the modular industry and elevators.

We also want the website to offer clarity and truth in an industry that has a faltering reputation. False claims and shoddy workmanship from some in the industry have created issues that need addressing. It was time to push back on outlandish claims harming the modular elevator business and the concept of modular itself.

We wanted it to be easy so we made pages for professionals, broken down by job title. We also have pages for each industry so product models can easily be accessed. Lastly, we now provide an easy, short Fast Track numbers form. It makes contacting us as simple as a few clicks.

So to put the new website navigation and content in a nutshell, here is what to expect:

Of course this website will not be static. It will grow and information will increase as we see new needs in the industry, so check back often.

The articles area or blog will also host tons of ideas. New concepts will be spotlighted creatively. Articles will be a serious to quirky look at the largest moving object in a building. Ultimately, the website will be linked more and more to case studies and examples of how we solved problems. Easy to use and find information will be through out to help you make a wise decision regarding elevators.

One person that has reviewed the site was impressed with the information we offered and the openness of the page. They thought that maybe the competition would just copy and paste our work into their site. To us that is not important. However we do wish they would mimic our quality so the industry can grow as modular elevators are the future. We are hoping the brand new website will make it clear that MEM elevators are quality elevators taking you to a higher level.

We hope you click all the links above and explore. But, if you want to cut through all that just click the button below. In a day we can get you solid budget numbers.

MEM Growth – Modular Elevator Manufacturing (MEM) is now distributing their high-quality modular elevators nationwide and as a result have doubled their factory floor space.

As the demand for a high-quality modular elevators has increased MEM is ready to meet that demand with a nationwide roll out of their products. Whether for schools, commercial space, hospitality, medical facilities, multi-family units or parking structures MEM can now meet the demand from the east coast to the west coast.

The key to the increased growth of MEM and new distribution effort is their desire to provide high-quality modular elevators as an alternative to traditionally build elevators. MEM President – Tom Shield is proud of the accomplishment and business milestone, “After 40 years in the construction business and over 20 years in the elevator manufacturing industry, it was time to allow our product to be sold and installed nationwide. We have a great team that knows elevators inside out and the consistent quality we provide has made this growth possible.”

He went on to say, “It is my philosophy that good business is quality business. We do everything that we can to mitigate drama, and low quality and high drama go hand in hand. As an example of safety our EMR rating is .75, which is excellent.”

Because of the continued, steady growth MEM has acquired additional manufacturing space. The factory floor now has twice the capacity of the already successful business. The expansion allows for improvements in the manufacturing process and allows the placement of more jobs inline for completion. It is a huge expansion that MEM is ready for according to Shield, “If you are looking for a better elevator alternative and would like to consider a high-quality modular unit for mid and low-rise projects; we are ready. Our team will answer any questions and provide a Fast Track budget number in hours or over the phone if you call in. We are excited about the new factory floor space and the growth to nationwide distribution.”

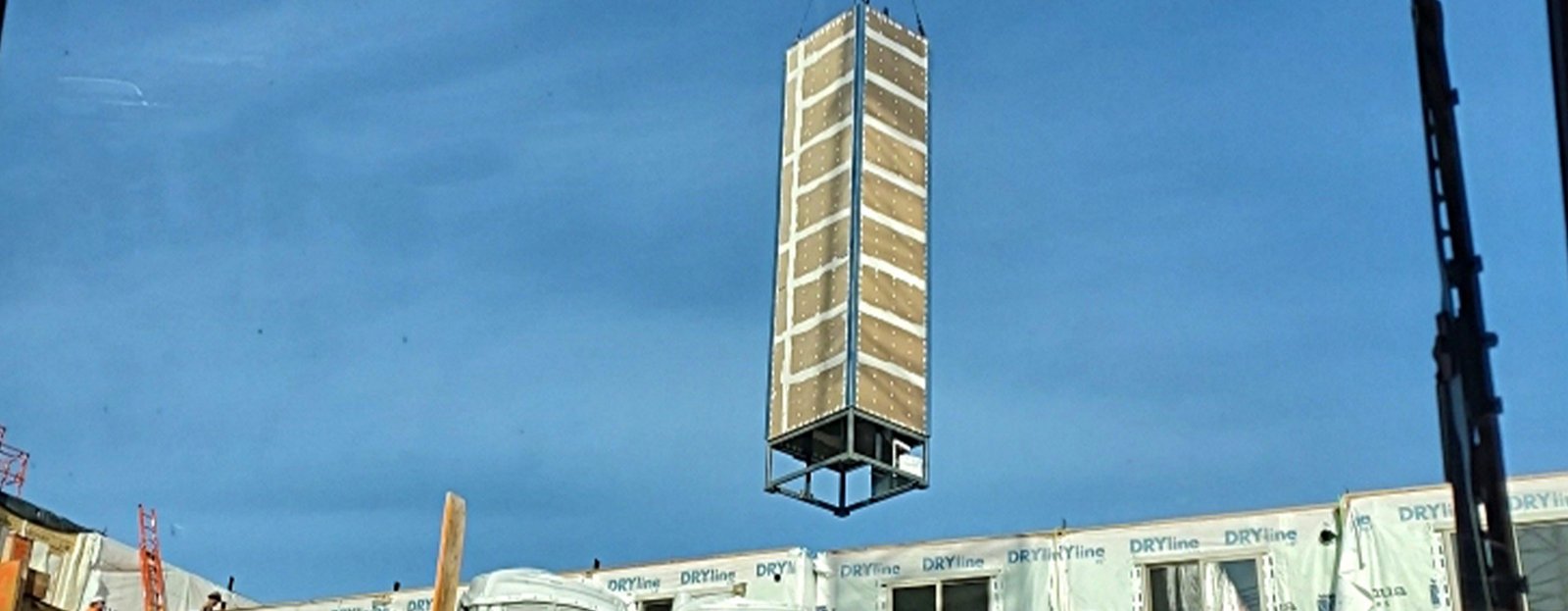

The modular concept for elevators is revolutionary and MEM is one of the pioneers that saw the need for safety, quality and fast set and start up. To summarize the difference between modular and stick-built you should know that they are simply conventional elevators, just unconventionally delivered and installed. Modular elevators are the hoistway, built with tough 4X4 inch HHS (Hollow Structural Steel), wrapped in mold resistant drywall to your specification with all the elevator components already inside. That means when they arrive at the site the wiring, cab, rails and other components are already inside the structure. It is then placed with a crane at the job-site in the elevator pit in less than a day and then can be started up in less than a week. This means that it takes the elevator off the critical path saving time, headaches and hassles.

Modular elevators are also extremely flexible in use and can be included in retrofit projects, modular projects or new traditional construction. Generally any time you would use a conventional elevator, a modular can be used in its place.

Lastly, when it comes to design, MEM elevators inside the cab and on the exterior of the hoistway can carry any look or feel. Architects are impressed with their flexibility. If you would like a budget number and be a part of MEM growth on a project you currently are considering, click the button below to get the process started.

Quality Elevators – When we say quality at Modular Elevator Manufacturing, it is not just empty words or a marketing ploy. We really mean it and we wished that everyone would take it as seriously as we do. Like you, we have heard the horror story from a project with a different company where, while the elevator was hovering over the building, an elevator jack literally fell out and plummeted into the pit. It could have killed someone.

The story is shocking and absolutely true. People were in danger. Beyond that when a company puts out a product so poorly built it not only potential can harm people on the job-site it can also harm the modular elevator industry and the modular industry as a whole. We all suffer the black-eye, when quality is not just suspect, but dangerous. But MEM is different and here’s how.

To start with MEM has just been at it longer. We didn’t just pop up out of no where with no construction or elevator experience. We have over 40 years in the building industry and a 20 year manufacturing track record of success and safety. We have never – never had anything like the scare of a 300 pound jack falling from the sky. Our installs go in smoothly because we have so much more experience.

MEM elevators are also engineered with safety in mind. Usually when you say safety and elevators you are talking about for the riding public and our elevators are very safe, never putting the general public at risk. But we have engineered our products so they are also safe to install as well. Part of the many pluses of the modular industry is that it means safety on the job-site. The heavy lifting and working in cramped quarters is moved to the factory with plenty of cranes and space on the factory floor. Plus there is no working at heights while the shaft is being built like in traditional construction. If huge elevator components are falling out of a hoistway that plus of job-site safety goes away.

With MEM we understand how important work site safety is and engineer that into each and every elevator we produce. It may take more effort, higher-grade materials and more care when building them, but MEM elevators are built for safety before, during and after the set and start up.

Lastly, we check every product we manufacture with our one-of-a-kind 10 Point Inspection by a certified elevator technician. Before the elevator is loaded on the truck, we make sure of the following:

Each of the above is a part of a process that produces consistent quality. If you are not careful you could pick the wrong modular company (the one where the jack fell out). Keep in mind that it is important that it is a certified elevator technician doing the checking and not just any old employee. We have multiple employees that are qualified and capable of checking everything out. We simply cannot vouch for what others are doing, but rest assured we do our best to make sure the elevator you get is the highest quality.

Lastly, we want to assure everyone that despite the most recent debacle, modular is the safest and best way to build. Whether you are considering the method for an entire building or wanting to retrofit an existing structure with a safe, fast installing modular elevator, reputable companies in the modular building industry are ready to build faster, greener and most importantly safer.

If you are curious about modular elevators and have a project in mind that you would like a quote for, click the button below. If you want to know more details about the accident that has caused such a stir, contact me at your convenience. I am always more than happy to explain why modular is the best solution and MEM is always quality elevators taking you to a higher level.

Elevator Babies – It was hard to resist putting a photo of my 6 month-old granddaughter in this article, but I didn’t because that would be way too much bragging and she is too young to be internet famous…at least among our 20,000 readers. But while holding her in my arms I got to thinking about how wonderful being a newborn is. No responsibilities; cry you get food; cry you get changed. Babies get to enjoy a short period in their life when knowing nothing is part of the job description and it is adorable. Sleep, eat, and be held is pretty much the day in a nutshell.

When it comes to the elevator business however, being a neophyte is far from wonderful or adorable. Elevators, need I remind people, are serious. They are costly, have thousands of parts and if they are improperly built they can be dangerous to the riding public. They are the largest and most complex moving component of a building. Knowing nothing about elevators or being elevator babies, but then selling them anyway is not cute or adorable; it is a hazard that can cost time, money and potentially cause injuries. But, that is exactly what you can get if you choose to call the wrong elevator company for a bid or project.

Modular elevators are just the same as stick-built in that regard, especially when you are talking about time and money. We all know that modular building is a wave that has already crashed the old-fashioned way of doing business’ party. It is the best option for any mid-rise building needing vertical transportation and will continue to be in the future. They are simply faster and better. But, if you are not careful, there might be an amateur on the other end of the phone line, selling you up and guessing at rules and regulations. After all when you call a modular elevator company you expect they are the experts in not only modular buildings, but elevators as well, but that is simply not the case if you call the wrong one.

One of the modular companies in particular out there that sells a cheap variety of modular elevator purports to be elevator experts. They are far from it and when you know the facts it can be a bit scary trusting a sales team that has no real experience. When I say no, I mean no. Three out of four of the sales team has a combined total of elevator or modular experience of less than a year. Yes, I said combined. My granddaughter has more experience being a baby than they do individually when it comes to elevators or modular units.

But it doesn’t stop there. The Quality Control Manager and Production Manager had no experience in modular building or elevators before coming to that company. Think about that for a second. The person that is supposed to be checking on quality has never checked for quality in the elevator business. In other words, watch out! Beware! Someone selling you an expensive piece of equipment and checks for quality and production that has a direct impact on your construction timeline has little knowledge beyond pushing the up or down button.

The person you are speaking to on the phone is not who you think it is when it comes to real world experience. They maybe elevator babies!

The good news is that there is an alternative to going to the nursery for elevator and modular advice and information. This is important to know as modular elevators are the future of construction.

MEM (Modular Elevator Manufacturing) is that knowledgeable alternative that has been producing elevators longer than any current modular elevator company and measures their experience in decades, not months. They have been there, done that time and time again when it comes to construction, modular building and elevators.

If you have gotten a quote from another company…give them a call before it is too late or if you have any questions about the benefits of modular elevators or how modular can make your life easier, I would recommend that you contact Hugo Beltran hbeltran@tlshield.com at MEM. You can also get started on your project by clicking Fast Track Quote. They are a company with experience that can give an honest, fair assessment of your needs.

Babies, especially my granddaughter, should be in the arms of someone that loves them, not on the phone dolling out sage advice about elevators like they are all wise through experience that does not exist.

My Monday morning observation when deep cleaning points to modular and modular elevators. When going through my desk in what should be an annual ritual, but too often neglected, I ran across an interesting item. Buried amongst the broke watches, a plethora of wires that go to who knows what devises and batteries (none of which still held a charge), I found a true vestige of the past; the old business card folder.

I remember wanting one when I first graduated from college as it was considered a true and genuine indicator that you were in business, much like the now rare, rigid leather briefcase. The folder was unique as it was a single place to put all of your valuable leads and contacts. It was one step above the old Rolodex as it was leather bound and portable.

I paged through the clear plastic sleeves of cards chuckling over the graphic design style of the various rectangles of 100% rag, 16 point stock that populated the folder. Each was a prized bundle of information I had collected over time and was once held dear, like a Stan Musial baseball card, but now I noticed how few were even still relevant. Businesses had closed or changed names, people had long since moved on or the information was out of date with AOL email addresses and FAX numbers prominently displayed.

But the cards, yellowed with time, were not the funniest part of what I discovered from my perspective. It is the very notion of keeping a catalog of cards categorized based on business type and then alphabetized all in a literal folder. The time for that kind of system has declined to the point of uselessness, worth little more than short lived amusement. That is why, despite a couple decades of usefulness, it found itself shoved to the rear of an over-packed desk drawer.

A better system for keeping track of people and business connections has emerged and in honesty leaves the old folder in the dust and ultimately in the circular file.

I have seen that change too in the elevator industry. There was a time not so long ago that the big elevator companies held a universal monopoly and if you were going to construct a low or mid-rise building you had to pay homage, live within their timelines and buy what they were selling. Thank goodness the old stick-built alternative is due for the dustbin of history just like my old business card folder.

Now if you want a high-quality commercial elevator you simply have to call MEM or email them for FastTrack numbers. Once you place your order you can break away from the control of the elevator industry for good. They no longer can dictate what you can do on your job site, building project or pocketbook. You will be free to schedule elevator work when you want it done, not the other way around. Free to choose who you want the elevator maintenance company to be with a fair contract, not one laced with automatic increases and non-proprietary parts. Deep cleaning indeed.

The barnacle encrusted elevator industry is and will fight back, but the march of time is lined up against them and ultimately modular will be the first and best choice for everyone. Not because it is new (it has been around for a couple decades now), but because it is a better solution. Faster, smarter, greener and can be less expensive.

That can all be said because building a hoistway in a factory, out of the elements and off site means higher quality, truer construction and no delays. Then putting all of the elevator components in the the hoistway while it is horizontal means no safety concerns of lifting heavy parts. The wiring goes faster and the cab is built to more exacting specifications. Just better.

So engage in a little deep cleaning and clean out your desk of all those old drawings, plans and specifications and get ready for the future with modular elevators.

Elevator Speeds – Everyone wants faster. Many especially are obsessed with a faster car, but that is just the tip of the iceberg. Faster cars. Faster computers. Faster internet. But it really doesn’t work that way with elevators. For most low to mid-rise applications only 100 (for low) to 200 (for mid-rise) feet per minute (fpm) is desirable and for good reason. Any speed above 200 fpm would most likely never be hit in most applications due to stops and starts. So wanting more speed would be just a waste.

To explain further, higher elevator speeds in most hydraulic elevators are never obtained because elevators do not launch like rockets and have to stop in relatively short distances. The rate the elevator takes off at is called the jerk rate (please insert joke here) and how fast it reaches top speed is called acceleration. Acceleration and Jerk (rate of change of acceleration) are human comfort considerations that must be taken into account when looking at elevator speed. The practical limits (for math geeks) are 4 ft/sec^2 acceleration and 8 ft/sec^3 for jerk. If you are a math nerd, or you’re wanting to test out your math skills, this is a good place to start. But take it from me, fastest speeds in most elevators are never reached.

Even at the regular rate of travel between 100 to 200 fpm if the elevator took off too fast the occupants would be thrown to the floor like a character in a Loonie Tunes cartoon. Well…maybe the cartoon is a bit of an exaggeration.

So then if this is pretty common knowledge in the elevator world, why are elevator companies like MEM (Modular Elevator Manufacturing) asked to quote unbelievable rates of travel for even two-story buildings, sometimes five-times the proper speed? Two reasons. One is an honest oversight and the other seemingly more insidious.

Let’s look at honest reasons first. Completed project specifications or spec sheets are filled with tons of information. Like the Dictionary of Architecture & Construction says a specification sheet is, “a written document describing in detail the scope of work, materials to be used, methods of installation, and quality of workmanship for a parcel of work to be placed under contract; usually utilized in conjunction with working (contract) drawings in building construction.” That is a lot of information that has to be captured, updated and controlled.

So when it comes to any building project it is a mammoth effort and elevators are often held separately with elevator providers pulling the info together to be inserted. That means that there is sometimes a lack of direct oversight early in the process regarding the elevator. Also, the desired specs out of need and convenience have been largely copied and pasted from another source.

The other honest mistake is when a company has had several projects of similar height or elevator travel. They feel the specifications can simply be copied and reused. Changes and updates are always meant to be completed, but sometimes the elevator speeds are missed and one or two floors of travel can mean significant changes. These kinds of “whoops” can happen, but the mistake is usually caught somewhere in the process. Countless times we have had to get clarification when the overall speed does not align with the project. We call and the correction is made.

Now for the more insidious reason aspects of specifications are way out of whack regarding elevator speeds. Sometimes when asked for information on pricing, big elevator companies use the opportunity to push certain products and features; right now they are currently promoting traction rather than hydraulic elevators.

A more cynical perspective is that over the long-haul the maintenance of a traction unit is twice to three times more costly and therefore more profitable for them. This can lead to big elevator companies suggesting products that absolutely make no sense. I have personally had conversations with multiple building owners and project managers of two and three-story building projects that were sold on the idea they needed a traction unit for more speed. In reality they needed no more than a simple hydraulic elevator with 200 fpm travel speed. The initial investment of going hydraulic is less and so are the legacy costs of maintenance.

Keep in mind at MEM we produce all types of elevators, so we are not pushing one over another, we just want to make sure that the elevator matches the project. So I guess my old Latin teacher was right “Caveat emptor” ~ Buyer beware. It is as true today as when it was first uttered.

If speed is still a concern, but you are thinking more about the speed of the overall construction process there is only one real choice in elevator that can move your along faster and that is a modular elevator from MEM. Contact Hugo Beltran at hbeltran@tlshield.com or call him at 800-755-9359. He would be glad to talk to you about the speed of elevators. For more research on modular elevators click here for our website.

Top 5 Elevator Complaints – When the calendar flips to a new year and after the smell of gunpowder laced with sulfur has dissipated into the heavens, almost everyone takes time for a little introspection. The question, “How can I improve?” crosses the lips of all as the past year must be assessed before it evaporates from our memory. If we neglect analysis we will be relegated to the role of fulfilling the time tested ode, “Those who cannot remember the past are condemned to repeat it.” (George Santayana-1905).

So despite the frenzy of streamers, poppers and champagne glasses clinking we must begin this exercise so easily left till later in the year. We must not fall into the trap of forgetting the past and becoming the fulfillment of the cliche. So let’s begin anew today and dive a bit deeper into the top five complaints general contractors and building owners have when it comes to elevators for their building projects.

What lessons were learned from 2019 or are we doomed to wash – rinse – repeat? Here are few common observations from the people that know best:

1. Elevators are always over budget. I am getting change-ordered to death.

2. The elevator industry forces me to surrender my job site when they want, work when they want and leave when they want.

3. I am held captive by proprietary parts, nebulous contractual clauses and auto-increases in fees.

4. Elevators are a part of the critical path so I have no leverage and no alternative.

5. My general building costs are through the roof because of elevator delays.

Do the above concerns sound familiar? They should. When polling our friends in the construction industry from general contractors to design build teams, these ranked at the top of the list for 2019 when it comes to elevator issues and always do. Somethings rarely change and this list of complaints is one of them.

So we have identified the problems; now what do we do about it? We can’t continue to walk in the same circle, over the same issues and the same concerns…or can we?

Fortunately, there is a solution that gets us off the merry-go-round, but it involves a little intestinal fortitude. It takes honest out of the box thinking and acting. That step is considering a modular elevator instead of the same old-same old? Modular elevators are commercial quality, use the same components as conventional elevators, are safe and come with benefits that you as an owner, developer or GC can only fantasize about.

First, you are buying a product in a complete form. It is an elevator hoistway made of tough steel, with all of the components already installed. This greatly reduces the possibility of change orders because when the elevator arrives it is a complete unit. The doors, the wiring, the hall calls, the rails and the car are already installed.

Second, the elevator literally is craned into place in a couple hours. No one is gumming up your job site for days at a time. Also we work with you to schedule the setting of the unit so you are not inconvenienced. Once it is place the actual start up only takes a handful of days.

Third, we never use proprietary parts and because of that you can use any elevator company you want for future maintenance. The power is placed back in your hands regarding legacy costs. Because we don’t use proprietary components the legacy costs are lower.

Fourth, the MEM process takes the elevator out of the critical path. Now the whole project is free to be managed to your needs, not the other way around. You don’t have to wait around for the elevator.

Fifth, with proper management the timeline for delivery, set up and start up can significantly reduce the normal general construction costs. The site is closed quicker leading to less cost.

The key to success is recognizing problems of the past and addressing them quickly, leaving them behind you instead as an obstacle that needs to be dodged or moved. With every multi-story project you are a part of in 2020 the elevator pain can be removed. Modular elevators can help you overcome the ingrained exercise of frustration and futility normally associated with elevators in construction.

So in 2020 when the smoke from the fireworks clears, the ball drops and the fog of the New Years celebration has lifted, assess the past and remove elevators from the list of irritation you face. Now it is time to try a better way. Give us a call, get some pricing on a future project and get information about how we can make your projects go smoother in the new year.

Ghosts Elevator – Ghosts of Christmas Elevators – With this Thanksgiving being one of the weirdest in holiday history, I felt moving right into Christmas was a great idea. By the way, be patient I will get to elevators.

One of my favorite collections of holiday movies comes from the time tested Charles Dickens classic, A Christmas Carol. Whether it is Bill Murray in Scrooged, George C. Scott, Reginald Owen or Scrooge McDuck it is a great story of the bitter, greedy and disillusioned Ebenezer Scrooge and the four apparitions that visit him.

They are charged with the last ditch effort to reclaim Ebenezer’s soul from an eternal, tortuous walk in chains around the earth as penance. It is a story of hope and reclamation. “I am here to-night to warn you that you have yet a chance and hope of escaping my fate.” Marley said. But would Scrooge heed the words of the mercurial spirits that came to sway his life decisions?

We all would like to think that we have the ability to change our minds or reform our thinking, but part of the appeal of Scrooge is it hits closer to home that we would like to acknowledge. Ultimately, we all tend towards intransigence in our lives like the lead character of the book. We walk the same paths, making the same decisions over and over. In other words, we start doing something a certain way and there we are, stuck in the mud just like good ol’ Ebenezer. Change? Bah-humbug!

In my shortened version of the “movie” in this blog, I get to play the part of Marley, wandering about with an over-sized ring of elevator keys jangling from my waist as I materialize in your presence. “You will be visited by elevator consultants of the past, present and future at the stroke of one, two and three.” I moan with my mouth agape. Unlike in the classic you get to decide whether you will change your mind or perspective on the past, present and future of the elevator industry, and thank goodness not the fate of your potentially wandering soul.

As the clock strikes one, you feel a nervous sweat drenching your brow. What will the early morning hold for you and your visitors or was the first visit all a dream brought on by a bit of “undigested beef, a blot of mustard, a crumb of cheese or a fragment of an underdone potato”? Could it all be true? But then with great fanfare enters the Ghost of Elevator Consultants Past. This jovial spirit reminds you of the elevators of years ago and how you were once filled with joy at the prospect of considering new and exciting technology in the industry. Thinking outside of the box was a delight.

Now it seems the business is the same old, same old, cut and paste and you are part of it. The life of exploring a better technology and improved methods was not something to hide from just a few years ago; it was something to embrace leading to newer and better. You are then shown through the spirit, that the old-fashioned conventional elevator model is a broken down relic of times past and a new faster, safer, greener and less expensive alternative, off the building project’s critical path is available if you are willing and able.

At the strike of two the Ghost of Elevator Consultant Present takes you by the hand and whisks you away to elevator projects in the midst of the building process where unsafe conditions of heavy lifting, scaffolding in hoistways and open shaft entrances make for unnecessary injuries. On that conventional job-site the sounds of drama and argument fills the air as bickering constantly exists between various trades. They squabble over pit ladders, electrical runs and limited site storage. But, then in a flash, you see with your own eyes a complete elevator set in place (hoistway and all the components installed inside) in a couple hours, up and running in a couple of days. No arguing, no waste and no unsafe conditions. You can’t help but shed a tear over the waste of time, materials, general costs and resources when you compare one with the other.

Finally, at the strike of three the third ghost appears. He quietly points a bony finger to the factory where modular elevators are manufactured. You effortlessly glide overhead to see there is less waste and more efficiency. The team on the factory floor work together in harmony on the production line with jigs and quality control measures that ensures a plumb and square hoistway every time and easy installation of components. The only heavy-lifting is done by overhead cranes and forklifts making everything safe and easy. Time then passes forward in a blur revealing the elevator being trucked to a job site and swung into place. The process is done in a flash; safer, faster, greener and less expensive. Is this future just a dream?

As you and the apparition drift weightlessly over the job site and back towards the factory, you see smiling faces of the elevator technicians, the building owner, the architect and GC. They have seen all the benefits of the high-quality commercial elevator made in a most unconventional way. Modular elevators have changed their lives for the better. It is a reality.

You release the robe of the last phantom and realize it is again the present day and now you recognize where he has placed you, at the door of MEM the most experienced and best modular elevator manufacturer in the world. Now the choice is yours, do you reject the past and embrace the future of building today? It is not too late! You still have time!

And if you choose modular as it says in the Christmas Carol (with my changes), “some people may laugh to see the alteration in your thinking, but let them laugh, and heed them little; for you were wise enough to know that nothing ever happened on this globe, for good, at which some people did not have their fill of laughter in the outset.” But in the long run they and others as well will come to know that for any low or mid-rise building a modular elevator is the absolute best choice.

If you are curious, but don’t want me to show up in your bedroom with three ghosts or if you are ready for a change feel free to contact us for more information. And for a Fast Track budget number click the button below. Hope you liked the story! – Happy Holidays from your MEM – Quality elevators taking you to a higher level.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.