Depending on the application an elevator cab may need to be extremely durable in the way it is made. It may also need to be outfitted with fixtures and a design that will impede or reduce possibilities of vandalism. Lastly, surveillance of the elevator cab is often a necessity as a warning against inappropriate behavior and as a way to visually see what is going down while the elevator is going up. MEM has a solution for all three circumstances.

First, regarding durability MEM cabs are made of strong 14g Galvaneal walls and the platform is 12g. Galvaneal is the preferred material for professional construction and commercial quality elevators for good reason. Its strength to weight ratio is vastly better than other materials including particle board. You may not think that the material used for the cab matters much because they can appear to be the same…until you have a mold problem or a broken pipe that leads to a waterfall into the elevator hoistway. One real life example of how going cheap on the cab can hurt your building project was demonstrated when a construction worker left the elevator door open and exposed one night on a competitor’s cheap wood core model and it rained.

The simple accident led to delays and hundreds of dollar of repairs. Even the interior panels swelled and warped beyond use. This is because particle board (no matter what acronym they use to describe it) is a wood substitute made from sawdust or wood chips and glue. When particleboard gets wet, it can swell or even disintegrate. That is not what you want to hear about your elevator cab.

Also, if sustainable construction is your goal, steel is a much better alternative. During the construction of your cab if particle board is used there is scrap and lots of it. That scrap contains certain chemicals that can be hazardous if not handled properly. This makes recycling difficult and some jurisdiction do not accept it at all as a recyclable material because it can contaminate other wood products. The problem is the use of urea formaldehyde in the glue, a primary component of particle board. It is a toxic substance that can be released during sanding or cutting. Good to know if you have to replace sections that get wet in your cab. Formaldehyde can cause eye and lung irritation, so respirators and safety goggles are required equipment when cutting or sanding.

If a particle board cab is the offer from another company, lookout! It may not be a true commercial-quality product. This warning is especially true in humid areas of the country or when the product is not in a climate controlled situation.

Second, MEM elevators can be equipped with fixtures and buttons that are tough, but still meet all required standards. They can also be produced with an interior finish that reduces the impact of vandalism. Elevator buttons get a lot of abuse, but some high-traffic areas get more than others. Parking garages, some schools and apartment complexes and more remote locations often face an onslaught of abuse. So, depending on your needs and location we can provide solutions to help.

This does not mean that the fixtures are not stylish or don’t meet the design requirements for any job you have in mind. They can be in square or round buttons in the cab or hall call and be in a multitude of colors and finishes.

Depending on traffic and use, diamond plate flooring may be needed and a random grind pattern design will help hide minor scratches and make cleaning up vandalism easier and faster. It is important to remember that vandalism is excluded in elevator maintenance contracts, so a little prevention can go a long way to reducing operating costs.

Lastly, We are not a security camera company, however we work with them all of the time. That means MEM elevators can be produced in the factory that can accommodate video surveillance equipment and systems. This helps you avoid the cost and headache of additional construction surrounding surveillance equipment. Cameras are a deterrent according to a leading elevator publication, Elevator World so if vandalism is a concern, it would be a good idea to work with an elevator company that has experience in security, integrity and a factory setting to help accommodate placement.

Ultimately this all means that MEM can meet your needs for true, high-quality elevators designed well with your needs in mind and fantastic looking elevator interiors that are extremely durable and will help deter vandalism. If you have a parking garage project or elevator in a high traffic area that may need a tough alternative just click the button below and let us walk you through our process and get you started today. You will soon see why MEM is the best elevator for any job between two and seven stories. Quality elevators taking you to a higher level.

Parking Structures – Modular Elevators Meet Demand – Getting ahead of the curve is important in any construction development or building project. Depending on the particular area and whether you are talking about urban or suburban parking, current trends are moving toward slowing the creation of new parking spaces overall.

Some developers, seeing the possibility of lessening demand, have engineered the possibility of future alternative uses into their parking garage design. Incorporating elements like increased headroom and eliminating the slopped floors, in an effort to create a “flexible use” structure.

They attribute the burgeoning drift to many factors. It is anticipated that the Millennial generation’s reduced desire to own personal vehicles, expanding ride sharing opportunities, increasing focus on public transportation and the promise of self-driving cars will reduce the need for the overall amount of dedicated parking space.

With the current climate, are we on the cusp of urgently needing more parking despite the apparent trends listed above?

With the current outbreak of Covid-19 and its ability to be transmitted in many urban settings and dealing with abuse of public transit by the homeless population, some are re-examining personal transportation as a growing alternative. Public transportation being a germ factory is not new despite this particular strain of the Corona Virus. In the 2008/2009 flu season in London a study was conducted by BMC Infectious Diseases seeking to answer the question, “Is public transport a risk factor for acute respiratory infection?” The answer from the report is, “Recent bus or tram use within five days of symptom onset was associated with an almost six-fold increased risk of consulting for acute respiratory infections.” In a nutshell public transportation seems to increase transmission of viruses.

Really? They needed a study for that? So if reduced public transportation occurs the need for efficient, fast, multi-level parking development in both the urban and suburban areas is or will shortly be needed. Personal car use may rise and parking needs increase.

Keep in mind that with parking, it is not about the overall spaces. It is about where the spaces are. We have plenty of parking spaces in the United States. About 500 million parking spaces (an estimated 3,590 square miles) serve this nation of nearly 326 million people, according to Andy Cohen, co-chief executive of the architecture firm Gensler. He predicts car ownership will peak around 2020 and then start to decline, with more Americans relying on some form of ride-sharing rather than owning their own vehicles by the year 2025.

That was before the Corona Virus stole headlines and people’s lives. Before comfort levels with ride sharing and public transportation began changing. Ride sharing, when analyzing the data, may not be the panacea some had predicted to alleviate long-term parking woes.

Just prior to the virus’ big splashy headlines and justified concerns Bruce Schaller, New York City transportation consultant, saw parking trends differently from others by examining actual car ownership. In his report The New Automobility he concluded that ride sharing has had the opposite effect intended and promised by many. He said, “vehicle ownership has increased in cities where Uber and Lyft are most heavily used…Moreover, the rate of vehicle growth substantially exceeded population growth in five of the eight cities (Boston, Los Angeles, New York, Philadelphia and Chicago).”

Then we get to the virus and it is not just paranoia. Consumer Reports as of May 8th, 2020 acknowledges problems with public transportation, ride sharing and taxi cabs regarding possible transmission. The list of suggested ways to avoid the virus when traveling includes renting a car and then cleaning it yourself, always wearing a mask when driving or riding, requesting only vehicles with glass separating the passengers from drivers or even just packing sneakers and walking. Not very practical. Besides, how do you clean your rented car before driving it?

So with car ownership on the rise despite other alternatives, and virus fears in the forefront of people’s minds, it seems that the need for multi-level parking will not stay flat or decrease but only increase in years to come. Not the predicted result many futurists had hoped for. Now to be clear there is nothing wrong with designing parking space that can be more easily repurposed or adapted in the future. That makes perfect sense especially when considering self-driving cars that can park themselves inches apart requiring less space. Although not a reality today, it may be within the life span of a building project. Forward thinking is important.

However, there will be a new normal when it comes to transportation and thereby parking space. The solution will eventually evolve, but parking will not diminish in the near future. One thing is for sure, the data reveals that car ownership is not subsiding due to ride sharing options and with “social distancing” becoming a standard phrase in our lexicon the mentality of individual travel or traveling as a family unit may become more of the norm, not less as anticipated. You may need more parking solutions faster.

So why is the modular elevator part of the parking solution for projects today and the possible increased projects soon to come? Because they are high-quality, commercial elevators that are durable and have elements specifically designed for parking structures. They also have pre-engineered drawings that can be inserted into plans, manufactured and trucked to the job site and installed.

Modular Elevator Manufacturing removes elevators from the critical path and reduces the headaches of coordination between trades. They are a solution for any low or mid-rise parking structure. If you have a current project for a parking structure or any other building between two and seven stories just click the button below to get a Fast Track budget number.

Stadium Chooses Modular Elevator – Elevators are a crucial part of any stadium and part of any good stadium design. Depending on the size, layout and capacity of the venue, anywhere from one to ten elevators or more may be needed. The purpose of the stadium elevator is to provide everyone unencumbered access, assist with foot traffic concerns and to meet American Disabilities Act (ADA) compliance. For instance the renovation to the venerable Dodger Stadium this past year added five new elevators to the existing two, significantly increasing accessibility.

To ensure access, elevators continue to be the best solution for vertical transportation needs. However, that solution comes with a myriad of problems when a project is in the construction phase if traditional or conventional elevators are utilized.

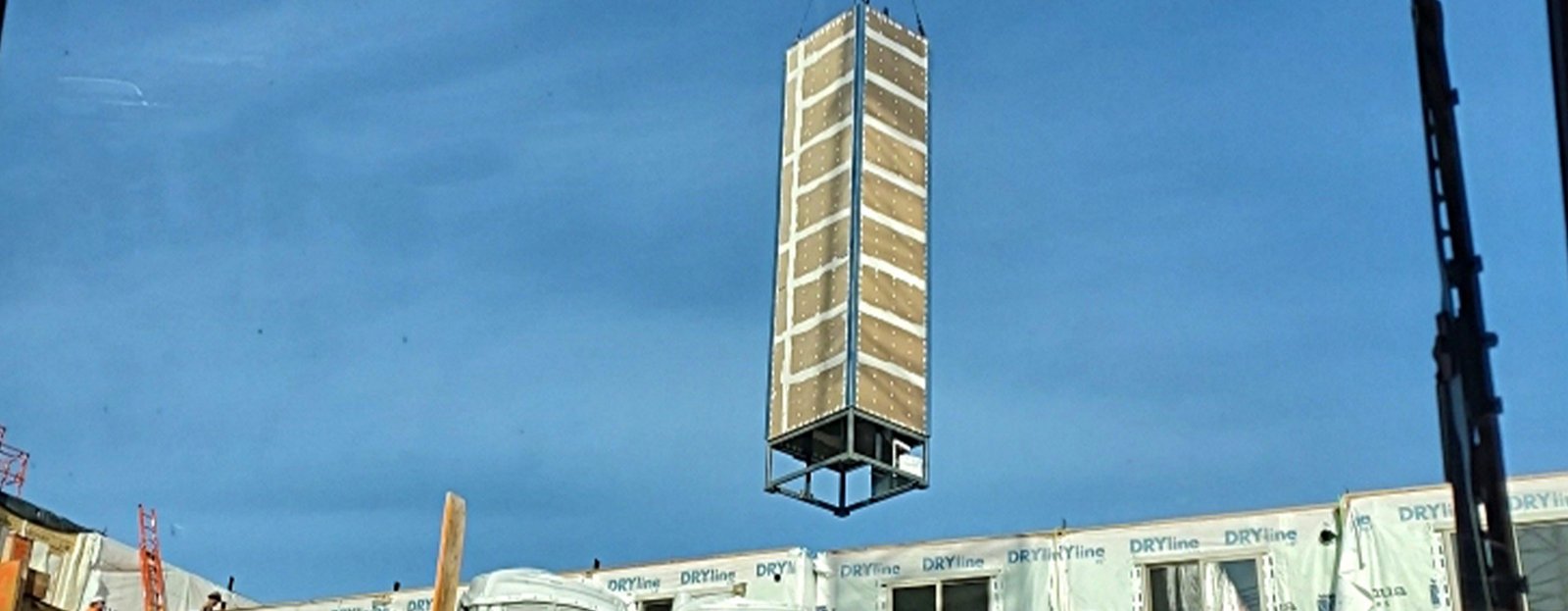

To alleviate problems with the elevator hoistway construction, component installation and then start up and adjustment the better alternative is a modular elevator. It is a conventional elevator built and installed in an unconventional way and it is the best alternative for any mid or low rise project. Instead of a cumbersome three-phase process where the shaft is built first, elevator is assembled inside second, and then it is turned on and adjusted, the first two steps are done completely in a factory. The elevator arrives as a finished product ready to be placed by a crane.

Most stadium elevators fall into the low and mid rise category, modular (like the one pictured) is the perfect solution.

The unique manufacturing process makes modular a better alternative for the following reasons:

In the stadium project shown, the modular elevator demonstrates its flexibility by being placed in an open area left specifically for the elevator. That was the best choice in this situation, however the modular elevator can be placed at anytime in the building process. Sometimes it get placed first and then built around. Other times it is the last piece of the building puzzle. We will help you decide what is best for your particular project.

Modular elevators can also be placed next to an existing structure or stadium grandstands or inside a building depending on the need. One of the most popular uses regarding stadiums is to retrofit our elevator to gain access to a press box or higher level of seating. However, as pictured modular is perfect for new stadium construction as well.

Practically there is no other alternative for stadiums other than to have elevators installed for access and compliance. So why not use a proven system that alleviates so many of the headaches associated with elevators in construction projects.

If you have a stadium or other building that needs a quality, commercial elevator just click the button below for a Fast Track budget number and find out like our other partners that we are quality elevators taking you to a higher level.

Modular – Affordable Housing Solution – In the United States there is currently an affordable housing crisis. With the current virus, it is easy to forget the need. However, it is estimated that we as a nation are at a minimum 7.2 million housing units short. That number could be much higher according to the National Low Income Housing Coalition. The result is any means that could shorten the build time should be considered. Easing the burden on the affordable housing construction industry would be welcomed.

Modular elevators are designed specifically to be an easy, fast, quality solution that many in the affordable housing sector are now looking for to meet the growing nationwide need. A reputable nationwide modular elevator company is needed.

This was the case recently regarding a 51-unit housing project in San Ysidro, an area of San Diego, California. Modular Elevator Manufacturing (MEM) was able to provide a quality elevator for the project and improve efficiency of the construction process. The affordable housing was needed and MEM helped with that need.

Patrick Meredith, Vice President of Construction at National Core, the developer, general contractor, property manager and primary catalyst for the project, decided to go with a modular elevator solution due to the benefits. He was excited to see the modular elevator craned into place and said, “The design of this project fit the modular elevator extremely well and we look forward to doing future projects with MEM.”

The San Ysidro project is a senior village with the purpose of increasing housing space in the San Diego area. But, this type of project is just one kind of various developments that National Core completes nationwide. They are a non-profit affordable housing developer, but their mission goes well beyond senior living and bricks and mortar. Family housing is also an important part of their mission and they strive to provide a community with improve neighborhood stability.

Also, through caring long-term management and maintenance they provide more than a place for families and seniors to live. They go as far as providing industry-leading services such as senior wellness, preschool and after school programs.

Regarding the San Ysidro project using a modular elevator, it is easy to see the benefits of the efficiency and time savings in this time-lapse video. Note that over half of the time-lapse is site preparation. What you do not see is that while the prep and foundation work for the site was being conducted, the high-quality modular elevator was being produced in the MEM factory.

When the site work was prepped and done and National Core wanted the elevator it was shipped on a truck and put placed in less than a day. The uniqueness of modular unit is that the simple looking hoistway in the video contains all of the elevator components pre-installed inside. Everything from the car, to the rails, doors and wiring are already done. This allows for smooth installation and faster project completion.

Meredith is convinced that modular is a wise consideration for the housing crunch saying that, “It was good to have everything dialed in.” regarding the elevator and in projects like San Ysidro “It was a perfect fit.”

If you are looking for a great alternative that can improve efficiency for your project, contact us or click the button below if you have a project in mind. We are more than happy to provide you with a Fast Track budget number in less that 24 hours. Whether you are in the affordable housing industry or any other, modular elevators are the best alternative for 10 stories or below.

Modular Elevators Improve Coordination – One thing I am missing right now is baseball. It is my favorite sport and I love to argue stats, history and of course which players are the best of all time. Does the list include Babe Ruth, Ty Cobb, Rogers Hornsby, Ted Williams, Stan Musial, Cy Young, Hank Aaron or all of them? Should we add more recent players like Jeter, A-Rod, Pujols, Trout or Ichiro? And what do you do with Bonds?

Anyway in my estimation, as a baseball purist, I hate the over-weighting of the long-ball in the discussion. Homers are fun to watch, but if time savings were really that important couldn’t they just cut out the overly dramatic trot like they did pitching four balls for an intentional pass? What I really like, instead of guys swing for the fence despite guys having two strikes, is the ballet that takes place on the diamond with a man on first and there is a drive up the middle. Will they turn-two? It takes perfect coordination.

Recently, when placing an elevator at a job site, the point of perfect coordination came up with the project manager. He said that you would not believe how easy the modular elevator made the entire project and how smooth things went because they went with MEM (Modular Elevator Manufacturing).

This was one of those projects that traditional elevator companies shied away from due to the way the shaft was integrated into the design. The project manager was a bit worried as it was his first modular experience. In the past he dealt with the elevator getting installed by a totally different company than the crew that builds the hoistway. This time it was all under the umbrella of MEM and the coordination between hoistway and elevator was perfect.

Because a modular elevator is a manufactured shaft to the dimensions and specifications of the project with the elevator components already installed it must be perfect, and is. In the factory, hand in glove or perfect coordination must and does take place with the buttons, car, rails, wiring and even hall calls factory installed in the horizontal shaft. It is like a well choreographed dance like a double play in baseball and it brings to mind the poem about the best known combo in baseball history a “Trio of bear cubs,” “fleeter than birds.”

Tinker – The hoistway is always perfectly square and plumb unlike their conventional counterparts. It is manufactured out of tough steel with an exterior sheathing and inspected for quality daily. It is the foundation and where everything begins.

To Evers – The hoistway is seamlessly passed down the line. Inside the rail placement is spot on and the car is aligned absolutely correct every time. The use of templates and jigs ensures a smooth ride and tolerances you will never see with a stick-built hoistway. The factory process makes all the components installed with ease and grace. Unlike the conventional process were the elevator car and components are built inside a cramped hoistway.

To Chance – The elevator is sent on to the job site and craned into place in a couple hours ready to be turned on when power is available. Each step is like the perfect double play with the team anticipating each others moves, perfectly timed.

But smooth coordination of the hoistway and elevator into one component is just the tip of the iceberg. In a building project any number of trades has to be managed and directed. It is a massive and costly undertaking to bring together all of the elements. There are dozens of workers and companies to schedule and then coordinate. The manager of this particular project said that the modular elevator helped with this too.

The modular solution removed the elevator from the critical path and simplified the project in a myriad of ways. There was no huge storage space required for crates of elevator parts and mechanic’s tools. No weather concerns delaying the elevator portion of the build. When the elevator was craned into place, it was done. All it needed was power to be brought to life in a matter of days not months.

It makes pulling the right strings easier for the management team, because there are simply fewer strings to pull.

One can argue the merits, qualities and contributions of particular baseball players forever. Who really was the greatest of all time and who deserves to be on a top ten players list? It depends on who you ask. Also what team you pull. Even what position you played growing up on bright summer days in little league or the sandlot has an influence. The stats can be used to bolster one over another and so the argument never really ends. That is part of the charm of America’s pastime. But with modular elevators, the debate is over.

There is only one conclusion. Modular elevators are the absolute best vertical transportation solution for any low to mid-rise project. And there is only one company that has the experience, proven record and quality that makes it the obvious choice. MEM. If you have a project in mind and would like to get a thumbnail number just click the button. You will receive a free, Fast Track quote. There is no doubt it will be a grand slam.

Covid Update – The corona-virus is changing the way we are looking at things in the United States and many businesses are struggling to keep their doors open and producing. Local restaurants, and small businesses are especially hard hit.

Thankful at Modular Elevator Manufacturing (MEM) we have not had any issues related to the virus and we are still shipping nationwide, but we feel we should let you know exactly what is going on at this time.

Hopefully this covid update virus will be over soon and things will get back to normal. Keep in mind we truly appreciate all of our friends in the construction business, suppliers and future customers and we are committed to help you in anyway we can. By keeping an open line of communication we can address any issues quickly and without much inconvenience or pain. Remember we are here to help. Stay safe and germ free!

Modular Building Perception – The modular building industry continues to grow and that trend will continue unless…

First, let me say that I am huge proponent of the modular industry and modular building. I have presented the concept at conferences. And I have even served in an advisory capacity in the industry’s leading advocate and educational group. It is not just a slogan that modular building is greener, faster and smarter it is! As a result I am excited to be a part of that construction movement. Also, I have written tons of articles on the benefits and need for more modular in the future. However there is a perception problem that could derail the industry despite our best efforts.

For me I saw this “modular building perception” problem rear its ugly head in a casual conversation. It was at an impromptu reunion of old friends. We grew up in the wonder years of cul-de-sacs and bicycles. Forty or so kids had summers to roam free in the backyards and empty lots of the Westwood Hills subdivision. As we discussed old-times we started naming the families and the various homes they lived in.

The Sullivans lived in the spit-level, white house with black shutters. The Jones’ house next door was the all brick ranch with the old Corvette in the drive under a tarp. We named the family and described the house all the way around the block and then we came to the Elmer’s Glue house. Everyone at the table knew exactly which house we were talking about. It was a modular home that arrived on the back of trucks in two pieces. With children watching it got craned into place. We, being just kids, made the leap that obviously the two halves had to be stuck together. Elmer’s Glue was the solution. The popular sticky, white, school supply stuck as well and so did the name.

Keep in mind that this is in the 1970’s. In our small town a modular building was an experiment more than a solution and unheard of at the time. When finished the house appeared very modest, plain and simple in comparison to the others in the neighborhood. Also, despite being put together in an afternoon it sat empty for months gathering dust and rumors.

The unfortunate result was a perception in the developing minds of the neighborhood youth. We started believing our imaginations that the modular units are held together with nothing more than the rendered bones of farm yard animals beyond their useful state and lack quality.

John Locke addressed this as he pondered what made mankind tick or think. He adopted the “tabla rasa” (blank slate) philosophy of Aristotle. He said, “Let us then suppose the mind to be, as we say, white paper, void of all characters, without any ideas; How comes it to be furnished?” He would argue that is it furnished with experience and perception. That experience and perception becomes our reality and everything going forward is compared to that ever-filling slate throughout life.

I am sure that Locke is rolling over in his grave at my simplistic understanding and application, but you get the general picture. Our reality becomes what we experience not facts. So when that seemingly low-quality house was being placed in our neighborhood, a group of young people filled the paper of their minds with a negative perception of modular. This does not mean that modular is low quality – far from it. It just means the perception is there and can persist.

Actual facts about modular construction have taken hammer and tongs at the perception for years and have been making serious inroads as modular becomes more and more popular, not just in the United States, but around the world. It is greener, faster, safer and more cost effective.

But, with the reality and facts comes dangers especially when a self, proclaimed modular manufacturer puts on the market an unsafe product. It confirms the unfair perception and will give the entire modular movement a black-eye hurting the modular building perception. The now filled blank slate will be reaffirmed and the chore of telling others about the benefits of the modular movement will become more difficult not less.

We have seen this with modular elevators. Modular Elevator Manufacturing (MEM) is working hard to promote the modular concept and part of that hard work and promotion is to make sure that the elevators we provide are actually high-quality and what we say about the product matches up with reality. When rumors abound that with another company parts fall out during installation it makes our job tougher. We have engineered quality into each product we manufacture and we have a ten-point inspection check list to verify our quality before the hoistway with the pre-installed elevator is readied for shipping.

Quality is extremely important not just for MEM but for the modular market as a whole. If pioneers of the industry such as MEM The pioneers of the industry like those at MEM continue to provide quality the future is bright. However, if also rans with low standards and low quality becomes what is sold, it will indeed be a difficult slog forward.

We love the modular industry and know most of our readers do too. So to preserve the reputation of the industry consider MEM not the others. We produce quality and our track record proves it and we are proud of it!

If quality and the modular build perception is important to you and you see a modular elevator as a solution click the button below. We will provide a Fast Track number in a day. You will find that MEM elevators are always quality elevators taking you to a higher level.

“The elevator holds everything up!” that is a common complaint among those in the modular building industry. Modular companies are growing by leaps and bounds. However, finding a way to incorporate vertical transportation quickly and smoothly was always a sticking point.

It is true that modular building is the future. It just makes sense as it means a high-quality project completed in a greener and safer way. But one of the biggest selling points with modular is the speed in which the project can be completed. Typically when you place traditional construction on a timeline there are gaps. After the permits and financing is set, the ground has to be prepped. Then the foundation is poured and infrastructure for the building brought in. Months tick by.

Meanwhile, despite the project being totally ready to go, the building makes it no further. There it sits as plans on a drawing board until the site is completely ready. Modular takes all of the waiting out of the process. The building can begin as the site is being prepped. In that way when the location is ready, modular units are ready to be immediately swung into place. It is estimated that modular building can reduce time significantly. This is because construction of the modular components can occur simultaneously with the site and foundation work. This means projects can be completed 30% to 50% sooner than traditional construction.

The modular process does speed things up incredibly fast, but there has been a huge fly in the ointment. The elevator. Despite advances in modular building, the elevator was mired in old-fashioned construction practices. Or the companies that built modular elevators were so low in quality that headaches outweighed any benefits of speed. Dangerous product were even being distributed. A new nationwide solution had to be created for the modular industry.

The results is MEM and we are increasing distribution to the whole nation. Now from New York to California and Florida to Alaska there is a true quality solution. A solution that is reliable and fast to set and start up.

As an example, realizing the need for speed and quality, MEM was called on a multi-family housing unit. It was completed on time and on budget with quality elevators. The builder’s experience had dictated that a conventional elevator NEVER gets the elevator done on time. But, they called MEM and got a taste of what we can do. Now they will never go back to any other way.

Soon modular builders will start using MEM nationwide and the complaint about the elevator holding up the project will disappear. It will be just like the solution we provided above and there will be no turning back from the quality and speed we provide.

If you have a project in mind and you are ready to try out a modular elevator, click the link below and we can give you budget numbers in a day. To fill out the Fast Track quote we just need a little simple information to get you started on a fast – safe – quality solution.

Trade Show Success! – The annual CASH (Coalition for Adequate School Housing) Conference was a huge success as it is every year. It always amazes the MEM team at how each year it grows. With that growth we get to meet new people and discuss vertical transportation for schools. CASH gives us a unique opportunity to meet not only the architects and superintendents, but people that use our elevators. From them we get to see how access is improved.

At our booth we hear the stories of replacing rusted out ramps or stairs and rickety old wheelchair lifts. For those in need and this gives us a boost of confidence and pride. Also, we are told of how we have helped save millions in additional costs. With our solution and quality elevators for new construction adding floors saves money instead of sprawling campuses.

This is not to mention the time and resources saved on the job-site when our modular elevator is chosen. We find being the best vertical transportation alternative very satisfying. We will continue to attend CASH Conferences in the future and share with our friends how we love to help.

As for those that do not see value in organizations like CASH. We feel it is their loss by turning their back on the needed mission. Some don’t attend so they can dodge questions about the safety of their product. Or maybe simply they don’t support California schools. We may never know. But one thing we do know is that MEM and TL Shield fully supports CASH and its mission. We look forward to a long relationship with them and the schools of California.

If you were not at the conference and part of the trade show success, but have a project in mind that we could be a part of, just click the button below for a Fast Track budget number. We would love to get started. Of course we will provide formal numbers or bid proposals at your request. Remember that MEM is the best option for any mid to low-rise building, especially California schools.

When you are the leader in an industry it is an obligation to educate, inform and instruct. When it comes to benefits and solutions of the products you create you must tell others. For that reason, Modular Elevator Manufacturing has launched a brand new website, modularelevator.net.

The purpose of the website is to clearly demonstrate modular elevators as the best alternative for low and mid-rise project. It is a new, easy to navigate way to increase awareness and information sharing about the modular industry and elevators.

We also want the website to offer clarity and truth in an industry that has a faltering reputation. False claims and shoddy workmanship from some in the industry have created issues that need addressing. It was time to push back on outlandish claims harming the modular elevator business and the concept of modular itself.

We wanted it to be easy so we made pages for professionals, broken down by job title. We also have pages for each industry so product models can easily be accessed. Lastly, we now provide an easy, short Fast Track numbers form. It makes contacting us as simple as a few clicks.

So to put the new website navigation and content in a nutshell, here is what to expect:

Of course this website will not be static. It will grow and information will increase as we see new needs in the industry, so check back often.

The articles area or blog will also host tons of ideas. New concepts will be spotlighted creatively. Articles will be a serious to quirky look at the largest moving object in a building. Ultimately, the website will be linked more and more to case studies and examples of how we solved problems. Easy to use and find information will be through out to help you make a wise decision regarding elevators.

One person that has reviewed the site was impressed with the information we offered and the openness of the page. They thought that maybe the competition would just copy and paste our work into their site. To us that is not important. However we do wish they would mimic our quality so the industry can grow as modular elevators are the future. We are hoping the brand new website will make it clear that MEM elevators are quality elevators taking you to a higher level.

We hope you click all the links above and explore. But, if you want to cut through all that just click the button below. In a day we can get you solid budget numbers.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.