At Modular Elevator Manufacturing we want to thank you on this Thanksgiving Day!

This has been a tough year in a number of ways, however we have continued to grow and expand. We realize that our growth comes from a dedicated team of professionals that manufacture, install and sell our elevators. Thank you to all the employees!

But, just as importantly we want to take this time of Thanksgiving and show our appreciation and heart felt thanks to our loyal partners.

We give thanks that together we make MEM a wonderful solution and a wonderful company.

Thank you!

We at Modular Elevator Manufacturing salute all those that have served our nation. We know that our freedom comes at a price, paid by the men and women of the Army, Navy, Air Force, Marines and Coast Guard. Many never return. We remember and honor all Veterans on this special day.

Thank you!

MEM Parking Garage Solution – Do you prefer aspirin? Tylenol? Advil? A caustic combination of all three? Imagine if you could avoid your headache as an architect or general contractor by not having to worry about the elevator in your project. That solution to your headache is available. And that solution can mean less materials, more parking space and fewer trades to coordinate. Imagine the stress and pressure relief when the elevator unit arrives when you want, fully installed! It is set in a total of four hours and totally off the critical path. It is not a dream.

Placed in hours you can have a Modular Elevator Manufacturing high-quality commercial elevator delivered to your site. All that is left for you to do is the exterior of the hoistway in any construction material you want. See the project below. It is a five-stop parking garage elevator, delivered complete. The durable commercial quality stainless-steel elevator car, was already inside. All the wiring – done, and doors, rails and even the pit ladder precision placed in the factory and it took less than four hours to set.

And this particular elevator came in two sections due to the total travel height. A crane placed the first section. The second followed right behind, easily bolted on top. They match perfectly as the manufacturing process assures the two sections will line up exactly right every time.

The hoistway is perfect, made with steel in a factory. There is no bowing, heaving or contracting like hoistways constructed of block or concrete. It also means that the rails are perfectly aligned. That produces the smooth quality ride you and your customers deserve.

MEM has the perfect solution for your parking garage project. That is especially true if you have designs or plans for several parking garages. Just spec us in and save time and money. Similarly, we can provide elevators for the entire project with solutions for any low or mid-rise application. So before another trip to the medicine cabinet, we’ve got you covered, whether the elevator is placed on the interior or exterior of any building, new or retrofit construction.

We have placed over 400 elevators and have over 20 years experience in making elevators as easy as one, two, three.

Finally, for your parking garage solution and a Fast Track budget number just click the button below. You will learn how MEM is the best elevator for any low or mid-rise project. Quality elevators taking you to a higher level.

6 Reasons Quality Matters – I have heard the phrase turned in a number of ways. “Close enough for horseshoes.” or “Close enough for hand grenades.” Another variant is, “Close enough for government work.” A friend of mine that worked at the local street department was very fond of that iteration. The quote then at some point got escalated to “Close enough for an atom bomb.”

As the old saw morphed, it went from basically a philosophy of, it is okay to be just good enough to beat the competition (in horseshoes) to, “Hey let’s try just hard enough to be in the same ballpark.” What that kind of thinking neglects is that (pre-Covid) there are a lot of different folks in the same ballpark (peanut venders to highly-skilled athletes) and each comes with specific qualifications and levels of accomplishment depending on the job. So, just being in the same general location skill-wise is meaningless.

Likewise, being in the general location regarding quality or “close enough” is not good enough either. Especially if your “close enough” is being compared to the blast radius of an A-bomb. That encompasses too wide a comparison where low-quality and high-quality are basically looked at as the same. To do a comparison like that is a huge blunder.

And who better to consult on quality than the guy who was actually in charge of quality control for nuclear weapons, Phil Crosby. “Close enough” in that line of work would mean a catastrophic disaster and he knew it, so quality was crucial.

Phil Crosby’s life was a life consumed with quality from his first job as a test technician to overseeing the production of the Pershing II Missile program. As the senior quality engineer he developed and implemented a Zero Defect policy. In that policy the idea of just getting by was rejected and perfection was put in its place. The policy he created produced a 25 percent reduction in the overall rejection rate and a stunning 30 percent reduction in scrap costs.

He was keenly aware that quality was not just a word to plaster on a website with a sly wink from the marketing guy, but needed to be deeply engrained into every aspect of the very culture of the business or organization from top to bottom. He said:

“Quality is the result of a carefully constructed cultural environment. It has to be the fabric of the organization, not part of the fabric.”

Phil Crosby

He knew catchy posters about quality placed in bathroom stalls or reward programs would not be good enough to produce true quality. They can be important reminders and incentives, but will never replace a cultural commitment. It has to be a top-down effort and philosophy emanating from senior leadership and permeating the organization at every level. Quality is crucial and should matter that much at every business. It does at Modular Elevator Manufacturing where we take quality seriously.

Here are the top 6 reasons quality matters for us at MEM. There are probably more but these came to mind:

The entire premise of modular construction is that by instilling factory processes into the construction trade, the industry can produce a higher level of quality, faster and often at a reduced cost. That is what we do at MEM day in and day out. However, when slipshod practices and lack of experience infiltrate the market, quality declines. Then the premise of factory production being better comes under attack.

Whether due to ignorance, no experience or a desire to make a fast buck, when quality is ignored the reputation of the industry gets sullied. The result is a better process that produces a better product (safer, greener and faster) becomes more difficult for the consumer to accept. Who knows how many dollars, how much time and how much energy has been wasted. How many injuries could have been avoided? All due to a very small number of businesses that do not see quality as important.

That is why at MEM we do not think “close enough” is good enough. We know that low-quality has a cost to the industry, the customer and to safety. We strive for quality in all we do. Whether you need a multi-family unit elevator or one for a medical facility, an elevator for a retrofit project or new construction we provide a quality solution.

If you have tried modular elevators before and found that the quality was not as promised and it ultimately cost you more than you were told, don’t give up. Instead give MEM a try. We live by the above list of 6 reasons quality matters. You will not be sold a bill of goods for a fast buck, but instead you will find a partner providing quality you can count on.

If you have a project in mind just click the button below, we can get you budget numbers in less than a day. Of course you can also call us anytime, and have a real conversation with an expert in the elevator industry. We are looking forward to talking to you.

Elevator Easy As 123 – Modular elevators with MEM are the easiest, high-quality elevators available today for low and mid-rise applications. Whether for new construction or retrofit projects MEM is ready to assist you. The simple three steps are manufacture, set and start up. The elevator arrives pre-installed. Flip through the brochure or download a printable version below.

Download a printable version.

MEM News. Modular Elevator Manufacturing is in the news again. Mark Madler from the San Fernando Business Journal conducted an in depth interview with our vice president of sales, Hugo Beltran and they discussed the significant growth in nationwide sales since the company made the move to increase distribution earlier this year.

Here is a link to the story here. Or download it below.

Modular elevators are the future for any low and mid-rise applications and the modular industry provides significant benefits to any project. It is a faster, greener and smarter way to build. However, without quality the benefits of modular dissipate quickly. That is why MEM is the leader in the modular elevator industry. MEM understands that quality is the biggest contributor to market growth and why they are so much different than others.

If you have a project that requires a quality elevator completed faster, greener and smarter, click the button below. With just general information we can provide a quote in less than a day. MEM is quality elevators taking you higher.

Speedy Multifamily Elevator Solution. One of the ways that young Americans have influenced the construction industry is that lately they have been prone to delay home purchases. This can be attributed to many factors including high prices for home ownership, a lack of the needed down payment and a delay in marriage and family. So, when they do leave their parent’s basement, generally they are renting in large numbers and not looking for the white picket fence.

The result is in many medium and large municipalities there is a predictable shortage of rental units and ultimately price inflation. Hence the multifamily building boom.

Governing.com demonstrates this through statistical data. They report that between the year 2000 and April of 2019 there was, “a median increase in the renter population of 31 percent…Over the same period, the number of owner-occupied dwellings also rose, but only by a median of 7 percent.”

That means building multifamily units is needed and needed fast. That need is further demonstrated by the recent number of multifamily unit starts as the market moves to fill demand.

According to Dodge Data & Analytics residential starts as a category only increased by 2% in July of 2020. That sounds pretty bad for business until you dive more into the numbers. Of those new starts multifamily units increased by a whopping 11%, while single family units (homes) showed an overall decline. Multifamily units are booming even in a tough Covid filled economy.

The above statements and stats are known in the industry, so what is the big deal? The big deal is that in a competitive market, speed to that market becomes extremely important. You want to be building on the upswing and not at the top when units get tough to fill. So any edge you can find to decrease the time of project completion the better. That speed is crucial as the fight to fill the void in housing becomes a race. The race will either be won or lost by various builders and design build firms.

Keep in mind that the race now includes not just general apartment complexes or condominiums. They are also a wide range of market specific dwelling spaces. Subcategories such as senior living, low income or non-traditional mixed use building projects are on an upward trajectory.

One of the time saving mechanisms was addressed on a conference call I attended with design build industry leaders. We were discussing the concept and current acceptance of modular as the solution to the speed of delivery dilemma. A participant, Patrick Kennedy of Panoramic Interests downplayed the diversification of the market, and maintained the time to build could be significantly reduced if they stuck to three types of building plans that could easily fit burgeoning subcategories. He said they have three plans, “Hamburger, cheese burger and deluxe.”

Depending on who, why and where the units were to be built, the basic plans all fell into those three types of designs. Then depending on what specifically was requested, the spaces use could be altered, just not the overall plans. That kind of consolidation of offerings is very wise and makes perfect sense when building faster and more efficiently is a priority as it is today. Faster is better and they found a great way to speed things up. But that example is not the only edge available.

In car racing whether it is NASCAR, Formula 1 or a soapbox derby speed is important. But, it is the small things that are done, sometimes months before we hear, “Drivers start your engines!” that are key. To create the success and speed on the track a lot must happen, as a simple turn of a bolt on the chassis setup could be the difference between the checked flag and as Dale Earnhardt would say being the “first loser”.

So if finishing a building project quickly is important (and we all know that it is) then finding even small ways to speed up the building process is crucial. Using simplified plans, as discussed, is one way to achieve that speed. But so is placing in those plans a time saving modular elevator. One of the biggest complaints we hear about the elevator industry is that with traditional installation the whole project becomes bogged down. It is slow and laborious. But, what if all of that installation can take place in a factory, rain or shine and the elevator can be delivered and fully installed in a day or less, on the day of your choosing? That is a game changer.

Reality Check It is also a reality and not some fiction or dream of the future. So now it is time for a “reality check” in the form of a few questions:

So here’s the thing with the speedy multifamily elevator solution. If you are honest you can see the time and financial benefits of a quality, commercial modular elevator. And honestly chances are your competitors already have seen the benefits. We know this because as the multifamily market continues to heat up, we have doubled our sales and had to double our factory space and capacity to keep up.

If you would like to have a discussion just call us or email and ask anything you want. We will always be straightforward and honest as we have been in the modular elevator business longer than anyone else, with more experience and have a record of integrity and quality. We have installed five times more elevators than all of our competitors combined.

So, if you have project in mind just click the Fast Track button below. Just a few questions and we can have a thumbnail quote to you in a day. The opportunity is there for the checkered flag; take it with the help of Modular Elevator Manufacturing and a speedy multifamily elevator solution.

Just the Facts on Modular Elevators. I am old enough to remember the classic TV show Dragnet. Sargent Joe Friday played by Jack Webb and his partner Bill Gannon (Harry Morgan) of the Los Angeles Police Department would have a weekly crimefighting adventure.

There were two catch phrases in the show. The first was in the shows open, “The following story is true, the names have been changed to protect the innocent.” And the second and even more famous from Sgt. Friday, “Just the facts ma’am.” In truth the character never really said that at all. He said a much longer version “All we want are the facts, ma’am.” But that aside, “Just the facts.” became as famous as his dry, monotone delivery.

Sometimes we forget the facts are really all we need. Sure I spend some time being creative on the blog and looking for ways for the info to stick, but in reality an elevator purchase needs to be based on facts. This is especially true if the facts are in your favor like in the case of modular elevators and the modular industry as a whole.

So below are just the facts on modular elevators and buildings. Look them over, check out what I am saying and then you can decide if modular is right for your next project.

First, an important definition. Modular construction is, “A process in which a building is constructed off-site, under controlled plant conditions, using the same materials and designing to the same codes and standards as conventionally built facilities – but in about half the time. The buildings are produced in ‘modules’ that, when put together on site, reflect the identical design intent and specifications of the most sophisticated site-built facility – without compromise.” That is from the Modular Building Institute the leading non-profit trade association serving modular construction.

To boil the definition down, modular construction is a combination of modular units (in our case a modular elevator) that results in just as high a quality (if not more so) that you would find in stick-built or site-built projects. The components are the same or better with the only difference being a modular unit is manufactured with more exacting standards, closer scrutiny and more quality control. Yet it is completed much faster.

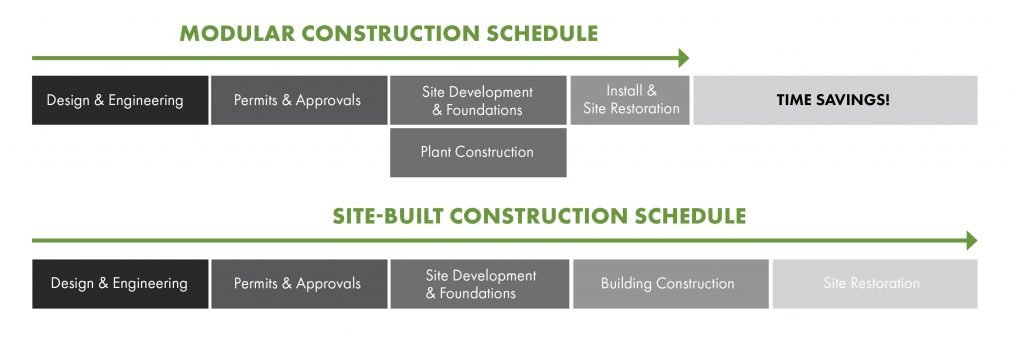

The process overall is faster as a factory can produce a unit faster than it can be built from scratch on site, but faster as well due to the time schedule of the entire build.

While prep work is being done the modules are being completed and readied for shipment.

The modular units can be almost any component of a multi-family buildings, hotel, school, office building or medical facility. Are you building an apartment complex? Modular can produce the entire living space including kitchens and bathrooms, common areas and of course elevators.

Do you need a medical office with a lab, exam rooms, office space, waiting areas and even bathrooms? It can all be modular. If you need to have multiple stories, the elevator from MEM is modular too. This process completely takes the elevator off the critical path.

With that said, let’s look at “Just the Facts.”

Just look at the facts on modular elevators in a way that would make Joe Friday proud and see that modular is the best solution for almost any project. But remember that modular elevators do not need to be in a modular only project! Modular elevators offer great benefits to any building project. To check things out more feel free to ask questions and examine the possibilities. The next step is to contact us for more information or for pricing on a modular solution. Just click the button below for a Fast Track budget number.

SEPT 23, 2020/Westlake, CA – Modular Elevator Manufacturing (MEM) has added new staff to increase capacity and meet growing demand. As the modular elevator manufacturer continues to increase its market share nationwide, a new IT manager, national territory manager, two new elevator technician trainees and elevator technician helper have been added. In addition, a marketing firm with national experience was added to the team.

Duncan McEwan, IT Manager will work to centralize the IT support and system management, providing a more consistent user experience for customers and staff though the improved integration of the IT systems. He previously worked as an IT Administrator for the Television Academy providing support for all of their activities, most notably, the Creative Arts and Primetime Emmy Awards.

This involved supporting the online voting process and hosting IT and audio/visual needs for the various panels that convene each year to vote for categories of Emmy Awards. He also provided the network access, both WiFi and hard wired for the press core at the Emmys Awards, including the WiFi for the Red Carpet. At MEM his experience will improve the customer experience and information flow.

Ken Grider, National Territory Manager brings his commercial and residential construction experience and modular elevator knowledge as well as a proven ability to drive business growth and increase market awareness. More than that, Ken is creative and a strategic thinker with strong communication skills and a strong desire to help customers find the best solution to MEM.

Jesse Ochoa and Jose Perez have been added to increase the ranks of licensed elevator technicians as they complete their training and Jose Galvin has been added as an elevator technician helper. This will ensure that as the demand for modular elevators continues to increase, MEM will maintain the largest and most qualified staff in the modular industry.

Additionally, to assist with the new national effort a St. Louis, Missouri area marketing firm has been engaged. Speiro Communications will help direct the effort to increase an already growing market share. Providing true quality and the most experience in the industry will be the cornerstones going forward.

California based MEM produces elevators from simple ADA compliant models to freight elevators. They are routinely sold in several types of buildings including educational, hospitality, healthcare, multi-family, commercial, storage and parking structures. The elevators are used in retrofit projects as well as new construction. For more information on MEM go to at modualrelevator.com.

If you would like to put the MEM team to work, click the link below to receive a Fast Track quote.

Elevator with a faster ROI. It started out as a simple conversation with a major investor (name withheld intentionally) with a hotel company at a construction job site. I was walking around with a camera around my neck and taking some video. As the crane roared in the background, he leaned over in my general direction and shouted, “Who are you here with?”

I pointed to the modular elevator being suspended by the crane and I said with equal energy back to him, “The elevator company.”

A broad smile crossed his face and he said a curious thing that I was not in the least prepared for, “Thank you.” he shouted.

With an inquisitive look I stammered back, “Your welcome?” He nodded still sporting that wide grin.

It then occurred to me that I had a very rare chance to speak directly to a major investor in the project. We talk constantly to architects, general contractors, elevator contractors, project managers and a whole host of others with various responsibilities, but it was rare to actually be at the job site and speak one on one with an investor. Our paths just don’t cross.

It is not rare that they check up on progress with on site visits, but as the elevator hoistway with all the components pre-installed takes only a couple hours to set it is rare our paths cross. And if he had the time, I would love to ask a few questions about his impressions and what stood out about the modular elevator. So I picked out his SUV…not difficult to do in the construction crew parking lot and camped out near there as I shot more video.

Eventually he appeared from the construction trailer and I asked him for a moment. He said he had a second or two he could spare, so I wasted no time. I introduced myself and asked what he thought.

Now, usually when you see a huge 15 ton object being swung into place at a job site on the end of a crane hook, people take a moment to look up and see what is going on and gaze in amazement. At a recent job in San Diego, faces dotted the windows in an adjacent building so onlookers could to get a peek of the elevator being lifted into place.

I have seen the curious have to be held behind yellow caution tape or with one project, a row of lawn chairs popped up across from a church getting its first elevator. So I imagined the gentleman I was speaking with would talk about how impressive the elevator looked being lifted and placed. I couldn’t have been more wrong.

“Its all about the ROI.” he said. “The return on investment is what excites me most about your product.”

He could tell by my stunned look I needed a further explanation. So he went on to say that with the modular elevator unit in his estimation, nearly 6 month could be trimmed off the total time usually allotted for the build. This significantly reduces the general construction costs. Because he made more money, faster from his perspective, he loved the MEM modular elevator.

He quickly laid out that with modular, while the ground is prepped and the concrete poured, the elevator and hoistway are being produced in a factory. So there is never a delay in hoistway construction. Bad weather doesn’t matter. The elevator can be set any time of year and problems with labor to build the hoistway are non-existent. Everything is done off site.

But beyond that, when the power is available they can use the elevator as a construction elevator. That saves even more money on the project. Finally, he indicated that there is no delay in getting it up and running. There is no need for extra space, extra parking, or having more people onsite stepping over each other. The elevator crew shows up for about a week and voila the elevator functions as intended, not months like usual. The elevator is totally off the critical path and the hotel can be occupied faster.

He summed it all up by saying, “That is why we love your product. An elevator is an elevator to me. Push the button and it goes up. But yours gives a faster return on my investment than any other. And no other elevator can change the timeline on an entire project for the positive.”

With that, as quickly as our impromptu meeting began it ended. He jumped into his SUV and sped off to the next project three states away. However, he gave me a lot to think about. Although an elevator with a faster ROI seemed important before the chance encounter, it now means even more to me.

My hope is investors and building owners that would like to shave time off of a project would click to find out more. They will ultimately realize a faster ROI on a building project if they do. We would love to talk to you about your project and how we can be a part of your solution. Modular Elevator Manufacturing – quality elevators taking you to a higher level.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.