A free elevator is a dream for many. Let’s face it, elevators are generally expensive if you want a good one. However, if you sharpen your pencil and your perspective you can find vertical transportation that provides enough savings to make even the highest quality elevator significantly less expensive.

But, to start the hunt for a free elevator you have to begin with a question. What in real terms makes up a commercial quality elevator that you find in any building project?

Well, in most basic terms it has to have an elevator car, rails for the car to ride up and down on and a hoistway the rails are attached to. That skeleton then has to have a heart. The heart is the conveyance system that makes the car raise and lower as well as open and close the doors at each floor. After that, to carry the analogy further, it needs skin. A great looking interior to the car with lights, buttons, hall calls and handrails. The hoistway can also be part of the skin in the form of a glass elevator and decorative finish or just a painted surface. That is what an elevator is in its essence.

There are two processes to accomplish the above:

The differences in the finished product of the two elevators are negligible (other than quality) as most of the component come from the very same supplier companies regardless of the process. Whether you are buying a modular elevator or have an elevator installed onsite each has the same pieces or the components have been through the same rigorous approval process. These two systems produce generally the same elevator.

So if the products are largely the same and roughly the same cost, how do you get one for free with modular, but not traditional?

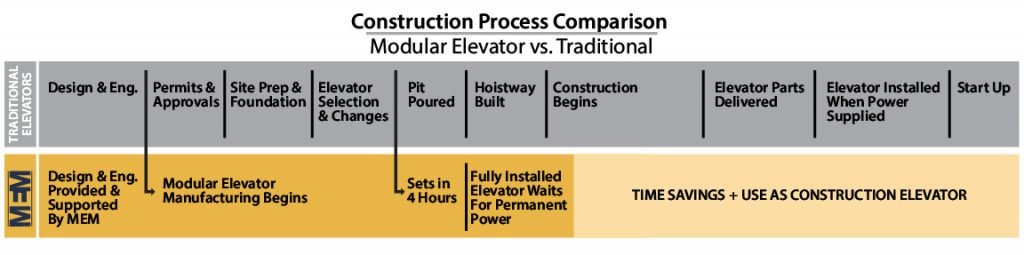

The answer is found in the savings that you can obtain because of the modular nature of the MEM elevator. The chart below explains the process for both. The traditional elevator is significantly different by the nature of how they are installed. They take much longer to cobble together on your jobsite when they want. There is design and engineering, followed by permits and approvals, site prep and the foundation and inevitable changes. Finally when the pit is poured and construction begins, the traditional elevator company lurches into motion.

They order parts and make sure logistically all the pieces and tools are dumped on your site with you contractually responsible. Then they start the installation process most usually after power is turned on.

MEM (the gold row) on the other hand arrives when you want. It takes the design and engineering that we have partnered together on and begins manufacturing. By the time the pit is poured the fully installed elevator is ready to be set in place. That takes about four hours (no kidding). As unbelievable as it may seem, you have a fully installed elevator sitting onsite waiting for power. Then when you are ready to have a fully functioning elevator turned on, we make sure it is started up properly. It is really that simple.

The traditional or old-fashioned way of putting in an elevator is at the end of the construction process. This throttles the completion and this is not idle speculation.

A thesis and study put forward by the Penn State College of Engineering supports this contention. In an actual parking garage construction sequence of a five-story project it was found that the elevators took a crazy 58 days to complete. Also, they were the last trade to get started other than landscaping and parking lot striping. They were also the last trade to finish. Now imagine changing that number of 58 days to ten, putting the elevators in first and using it as a construction lift like we did at San Jose State.

The date the parking garage opens comes sooner as the job closes faster. This reduces overall costs in addition to other benefits. No more making space for storage of all of the parts and pieces. Big sections of projects are cordoned off for this purpose. That slows the project. Not to mention all the coming and going with a big carbon footprint. Also they are burning your electricity to install the elevator. MEM’s elevator comes pre-installed.

Lastly, with a modular elevator once power is on and adjustments are made, you can use it as a construction elevator.

So now sharpen your pencil and put a dollar sign beside each item listed below. How much is it worth that:

As you can see with the above list and a sharp pencil you can save ten of thousands of dollars or more by using MEM elevators on every low and mid-rise project. The general conditions alone can run tens of thousands per month. So when you balance the costs and savings, you can have a higher-quality elevator installed when you want for less.

Is the elevator really free? Nope, but the savings you will gain using an MEM elevator will often be more than your investment. Not to mention the faster occupancy rate that has as an additional benefit. I was once thanked for trimming months off a project putting more money in the investor’s pocket on a hotel project.

So summing it all up isn’t it time to at least consider a modular elevator for your next project? To get the ball rolling all you have to do is click the Fast Track button below. The form asks a few easy questions and then we will contact you with an obligation-free budget number. If you want to do a little more research join a Live Virtual Tour of our facility to see how we produce the highest quality commercial elevator that installs in hours. Just click that button to get on the schedule.

Here is a short time-lapse video of a modular construction project that incorporated two of our modular elevators. The first is on the right side of the screen at :24 and the second on the left side of the screen at :59. The second elevator was also used as the construction elevator on the project. That saves time and money.

This fantastic project is by our friends at Pacific West Builders. They are national pacesetters in the modular construction industry. And MEM is the leader in the modular elevator industry so it was a seamless match.

MEM has more experience and higher skilled personnel than any other. We provide quality – consistency and simplicity for every job we do. If you contact us you will see the difference we make.

Whether you have a modular construction project or any other type, if you want the safer, faster, greener and smarter alternative click the button below. We are perfect for all low or mid-rise projects. Also, you can now schedule a LIVE VIRTUAL TOUR OF OUR FACILITY!

Elevator Install Video – Here is just a real quick video on our last installation. In this particular project multiple elevators were requested. We placed 2 fully installed elevators in about 4 hours.

Amazing!

MEM is the leader in the modular elevator industry with more experience and higher skilled personnel than any other. We provide quality – consistency and simplicity to every job we do. If you contact us you will see the difference we make.

If you want the safer, faster, greener and smarter alternative for you next low or mid-rise project click the button below or contact us.

When you get over a couple of stories in a building project a man lift or construction elevator becomes a reality. Numbers bear it out even if it is a requirement based on number of stories. The need is there due to the cost of having a construction team without one tromping up and down stairs all day. Workers are simply less productive, so although the cost is often hidden in hours lost by using a staircase, it is real and real expensive.

But, then you have the added cost to your project for the temporary elevator, plus availability, the set up and inevitable delays. It seems you are either paying too much for the savings if you get one or you simply don’t have a construction elevator onsite at all because for a low or mid-rise project it seems cost prohibitive. So, here’s the question: Why use a temporary construction elevator at all when a permanent modular elevator could be used instead?

It makes perfect sense. A commercial quality, modular elevator can be placed and turned on when electricity is available at the jobsite. When construction is finished, it becomes the permanent elevator.

Now before I get started, let me say up front that this is not the perfect solution for every job. If your desired use is not a low or mid-rise project it is probably not a good fit. We are simply not the best solution for high-rises.

Also, if you are wanting to move tons of palatized materials, likewise we are not a match either. Elevators designed for passenger use usually have a capacity of between 2000lbs and 5000lbs. We, of course, can make elevators that have a huge capacity weight-wise, but the cost would outstrip the benefit once the building is opened.

In addition, passenger elevators are limited in size generally. First, you have the cab size. We can make elevators with a cab big enough for a hospital bed (the only limitation is getting elevators under the overpasses on a flatbed truck). But then you have the door issue as well. Usually, passenger elevators have door openings of 36 or 42 inches, although some can be wider. Keep in mind the door opening does not extend across the entire elevator cab. So, if you want to take items to the top floor larger than the cab or the door opening our elevator is not the best way.

There are plenty of other solutions that do not involve an elevator at all if moving big, heavy items is needed. But in most construction scenarios we are the solution or at least worthy of consideration.

I like to say that this blog is designed to be informational and not just a sales pitch. The above is exhibit A of just that. Shoehorning us into a project where it is not a solution makes no sense and damages our credibility. It also damages the credibility of the modular concept overall. We can think outside of the box, and have even made round pegs fit into square holes (see this corner post project) but, modular is not always the best solution.

However, in the majority of construction projects, at the low and mid-rise level we are the solution. This is especially true if you are looking to cut costs regarding the use of a temporary elevator during the construction phase.

In other words, if moving men, tools and some materials is needed on building site, that role could be filled by the modular elevator quite easily and at minimal additional costs.

So, when you start looking at your construction schedule and logistics think about the elevator first. This is not an earthshattering thought. It is common practice for the hoistway or hoistways to be the first item on the drawing board along with stairs. But, here’s the change… don’t think just hoistway. Think fully installed elevator.

MEM elevators are the hoistways and fully installed elevator. They are a steel shaft wrapped in drywall for fire protection with a complete elevator already inside. The elevator car, rails, wiring, doors and frames are in place when it arrives at the site. In the example video below, that is what you are seeing; a fully installed elevator being set in a building.

Most projects require about 4 hours to get the elevator craned into place.

Then the start up can begin once there is electricity at the building site. Because everything is generally already installed, it takes about a week to get the elevator running. With the inspection, and following the appropriate rules for a construction elevator the modular unit can be used during the building phase.

To make the above possible keep this in mind regarding modular elevators:

Modular elevators (especially from MEM) can help you on the jobsite as both a construction elevator and passenger elevator. It can replace the cost of a construction elevator or it can bring a construction elevator to a job where one was not considered due to cost. It maybe time to consider the benefits of a modular elevator as your construction elevator solution. Click the button below below for a Fast Track quote and to get the process started.

Affordable Housing – Modular Elevator Solution. No one can deny right now there is a problem for urban areas of all sizes and that is affordable housing. According to the most recent stats from “The State of Homelessness in America” a publication of the Council of Economic Advisors, a half-million Americans struggle with housing. 65% of that half-million can be found in homeless shelters while an astonishing 35% or nearly 200,000 are on the streets.

But, I really didn’t need to give you the stats. A stroll down the street in many of our cities reveals the problem without reading a detailed report. Homelessness abounds.

At its core the issue is one of supply and demand. Simply put, there just are not enough residences for a myriad of reasons. As a result the law of supply and demand dictate that many of the homeless are so, because they are priced out of the market. There are just too few housing options. The supply is low – the demand is high and that makes prices likewise high.

One solution is to reform the laws and codes in local jurisdictions that have helped create the problem. Unsurprisingly, the report lays blame at that door and maybe deservedly so. But, good luck with sweeping legislative change, let alone sweeping change fast.

The current political climate in most urban areas makes wholesale changing of housing laws for the better a pipe dream. With that reality it makes the only other solution increasing the supply of affordable housing. The alternative is turning a blind-eye to the problem or to burry our collective heads in the sand.

If more units are the best solution a couple of hurdles need to be crossed. Both time and space need addressing. I am not taking about Albert Einstein and the theory of relativity. Where (space) the housing units can be placed and how fast (time) they can be erected is the concern. This is an immediate crisis and one that will not go away without action so, the faster new housing can be readied for occupancy, the better.

When it comes to housing where it is placed is always key. I recently toured neighborhoods where two completed affordable housing units where ready for occupancy. During the tour I noticed that surrounding the new modular buildings were rows of houses and small apartment complexes. They lined the street, crammed closely together. The houses were probably built in the 40’s or 50’s and most of the houses were still occupied. Several showed a high level of pride in home ownership. As a result it would be unrealistic to acquire those properties in bulk to create a new, sprawling complex. It would be costly and inefficient.

I did however, notice two or three dilapidated units, usually grouped in clusters. There were no rose bushes or neatly trimmed lawns. Graffiti was more common than a car in the drive. They were obviously abandoned. So more housing could be more easily accomplished to use those small narrow lots, instead of buying and bulldozing dozens. But, solving this problem takes more than just a new house being built in place of the old. Multiple units would have to go in that space. That means building up. In the two units I toured it meant a modular elevator.

The second you say “elevator” in any project that is time sensitive eyes roll. Everyone knows that traditional, old-fashioned elevator installation wrecks the timeline for completion. Tacking an additional 6-months, a year or more to the completion date is not unheard of. So, building an affordable housing unit with a traditional elevator is not addressing the immediate need at all. It certainly doesn’t show the homeless population much compassion for the plight they are in, especially when there are alternatives.

Modular building is a much faster option. In the two examples I visited both were purely modular. However, a modular elevator can be used in any type or building project. Even retrofit applications can have a modular elevator installed.

The time savings is because the elevator being built as a completed unit in the factory while the project is still in the process of site prep and permitting. They are then delivered to the jobsite as finished elevators.

Modular elevator units from Modular Elevator Manufacturing can even be used as a construction elevator as they are delivered when you want them.

The elevator is placed in less than four hours and when power is provided they are started up in less than a week. The elevator is removed from the critical path. Problem solved.

Time and space has been inextricably combined by Albert Einstein. His theory linked both into one entity. The same is true with the housing crisis we face.

Time and space are huge obstacles that are linked in the quest for affordable housing. Modular elevators are the solution to addressing both problems at once. The space available means to address the housing crisis we are forced to build up in multi-story units. However, concerns over time constraints and the need to act quickly have dampened the enthusiasm for a multi-story solution. Modular elevators put that solution back on the table. It has worked successfully already in a number of projects we have been a part of.

We are ready to discuss a vertical transportation solution for any low or mid-rise project. Hopefully, we can be a part alleviating the issue of homelessness. Affordable housing is an immediate need and we can be part of the solution. To get the process started just click on the button below. We can provide you with a quote in less than a day.

Perfection is a word that is not used very often. And it is also almost never used in the construction industry. But, there is such a thing as perfection even in the building trades and it is more common than you think. Its just not common with a traditional elevator installation. With MEM elevators however, perfection comes easy and it is a good thing it does.

Maybe we think of perfection being so rare because when the word is used in everyday conversation it is often associate with singular events or rarity at an extreme level. Think about a perfect game in baseball. In nearly 220,000 games played in Major League history, there have only been 23 official perfect games pitched and no hurler has thrown more than one.

No one claims to have ever had a perfect golf score…it would be 18 for a single round. Instead we measure ourselves against par. Even past North Korean leader Kim Jong-Il could only muster a score of 38 with 11 holes-in-one in his fabled round. Pretty good for the first time on a golf course, but still no where near perfection. Although if prevarication were a sport, Kim would at least come home with a medal.

Speaking of medals, in gymnastics perfection was so rare that when Romanian, Nadia Comaneci reached perfection in the 1976 Montreal – Summer Olympic games, there weren’t enough digits prior to the decimal point on the scoreboard. To the confusion of the crowd, after a seamless performance the score was shown as a paltry “1.00” instead of the ten she had earned.

But, astoundingly at Modular Elevator Manufacturing (MEM) perfection is commonplace, especially when it comes to the hoistway. So here’s why that accomplishment is so important and the how we daily accomplish such a seemingly rare feat; the feat of perfection.

A hoistway, otherwise known as an elevator shaft is the backbone of the elevator system. It must be perfectly plumb and level. Just like in human anatomy where everything hangs from the backbone, so too do many of the elevator components hang from the shaft.

Like the old song “The head bone’s connect to the neck bone.” etc. The elevator rails are connected to the walls of the shaft. On those rails the elevator car rides. How plumb, level, stable and sturdy that shaft is often determines how smooth and quiet the elevator car will go up and down.

If you have ever been in an elevator car that rumbles, or rattles it may be that the backbone (hoistway) is out of alignment. That can shorten the life of the elevator system and drive the passengers riding in it a bit crazy.

In simple terms, the reason for the rattling in traditional elevators is often that clips are attached to the inner hoistway wall and on those clips the rails are attached. The worse the alignment of the hoistway the more adjustment is needed. And the longer and more effort it takes to get the rails set right. If the hoistway is out of plumb or worse yet twisted even slightly, additional strain can be created on the rails and then on the clips. That can force the mechanism to be pulled loose as the elevator is used over time.

With a modular elevator the shaft is so plumb and level that the clips are not simply attached, but spot welded onto the frame of the hoistway and then bolted. They are adjustable, but aren’t going anywhere and there is no need for them to move. They can be welded because the hoistway is perfect every time. That means that modular (as usual) outperforms traditional.

First, to understand how perfection is possible it maybe helpful to know why traditional elevator hoistways are so often out of whack.

With the old way of putting in an elevator (and we have all seen this on a construction site) the elevator hoistway is one of the very first things that goes up. If it is cold, wet or snowy the elevator hoistway can heave and shift. One builder in Canada got tired of seeing shafts having to be redone because of heaving and the expense of hoarding heat while the hoistway cured. So he wisely opted for modular.

The opposite is true as well. If the temperatures are over 100 degrees special care and extra-effort must be made to keep the mortar hydrated with block construction. Failure to do so can “affect normal strength development of mortar, leading to a reduction in strength.” – cement.org. That’s a scary thought.

Extreme heat and cold say nothing about the poor folks laying all that block or pouring cement. They work in any number of foul weather conditions. And as we all know in less than optimal weather, work quality can diminish. In addition when it comes to the traditional hoistways work is done at heights on scaffolding. The human element cannot be ignored.

The hoistway tends to shift, twist or lean ever so slightly.

With a modular elevator or modular shaft or hoistway weather is never a problem. The entire hoistway is built inside a factory. The hoistways are made of tough construction-grade steel, laid out on jigs and are then welded together. There is no working at heights as the shaft is simply rotated as needed.

They are laid out horizontally in fifty foot sections or shorter depending on the project. If a hoistway over 50′ is needed the sections are laid out together to insure they are plumb and straight. Connecting plates are added at the joints for perfect fit every time.

Next metal c-studs and additional bracing is attached followed by the exterior sheathing. Usually a mold resistant drywall is used for either one or two hours of fire protection. The hatches get elevator doors next, then the rails go in. They are then aligned and welded to the interior and then the interior walls are finished out.

Perfection.

This perfect hoistway makes a solid, stable, plumb and level backbone for the elevator system. It ensures a great elevator every time. You will never get that promise from any GC or elevator company regarding the hoistway they build on-site. If this process intrigues you in the least and you have a project in mind just click the button. We can send you a quote in 24 hours. Or contact us at MEM where we produce elevators taking you to a higher level.

Just the Facts on Modular Elevators. I am old enough to remember the classic TV show Dragnet. Sargent Joe Friday played by Jack Webb and his partner Bill Gannon (Harry Morgan) of the Los Angeles Police Department would have a weekly crimefighting adventure.

There were two catch phrases in the show. The first was in the shows open, “The following story is true, the names have been changed to protect the innocent.” And the second and even more famous from Sgt. Friday, “Just the facts ma’am.” In truth the character never really said that at all. He said a much longer version “All we want are the facts, ma’am.” But that aside, “Just the facts.” became as famous as his dry, monotone delivery.

Sometimes we forget the facts are really all we need. Sure I spend some time being creative on the blog and looking for ways for the info to stick, but in reality an elevator purchase needs to be based on facts. This is especially true if the facts are in your favor like in the case of modular elevators and the modular industry as a whole.

So below are just the facts on modular elevators and buildings. Look them over, check out what I am saying and then you can decide if modular is right for your next project.

First, an important definition. Modular construction is, “A process in which a building is constructed off-site, under controlled plant conditions, using the same materials and designing to the same codes and standards as conventionally built facilities – but in about half the time. The buildings are produced in ‘modules’ that, when put together on site, reflect the identical design intent and specifications of the most sophisticated site-built facility – without compromise.” That is from the Modular Building Institute the leading non-profit trade association serving modular construction.

To boil the definition down, modular construction is a combination of modular units (in our case a modular elevator) that results in just as high a quality (if not more so) that you would find in stick-built or site-built projects. The components are the same or better with the only difference being a modular unit is manufactured with more exacting standards, closer scrutiny and more quality control. Yet it is completed much faster.

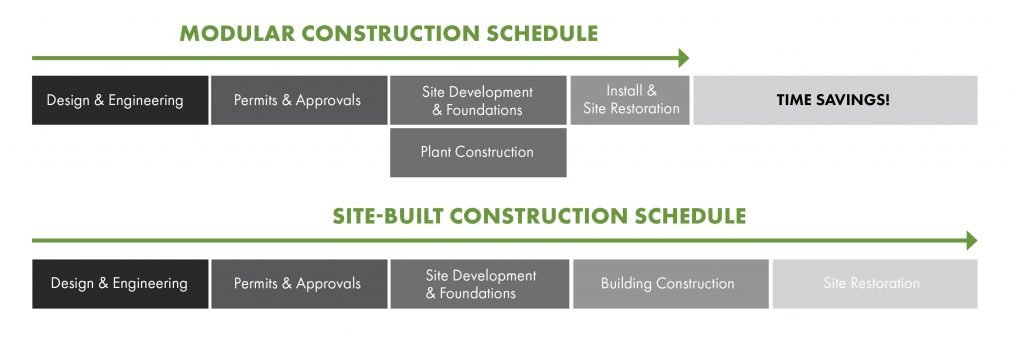

The process overall is faster as a factory can produce a unit faster than it can be built from scratch on site, but faster as well due to the time schedule of the entire build.

While prep work is being done the modules are being completed and readied for shipment.

The modular units can be almost any component of a multi-family buildings, hotel, school, office building or medical facility. Are you building an apartment complex? Modular can produce the entire living space including kitchens and bathrooms, common areas and of course elevators.

Do you need a medical office with a lab, exam rooms, office space, waiting areas and even bathrooms? It can all be modular. If you need to have multiple stories, the elevator from MEM is modular too. This process completely takes the elevator off the critical path.

With that said, let’s look at “Just the Facts.”

Just look at the facts on modular elevators in a way that would make Joe Friday proud and see that modular is the best solution for almost any project. But remember that modular elevators do not need to be in a modular only project! Modular elevators offer great benefits to any building project. To check things out more feel free to ask questions and examine the possibilities. The next step is to contact us for more information or for pricing on a modular solution. Just click the button below for a Fast Track budget number.

We are in the news!

Los Angeles, CA. July 23, 2020 — MEM Doubles Factory. Modular Elevator Manufacturing (MEM) has now doubled its production facility. This is in response to a significant increase in sales growth as a result of a new nationwide marketing and sales campaign. Interest in the high-quality commercial modular elevator product is way up due to the national strategy being employed since the beginning of 2020 and the uniqueness of the product itself. MEM elevators are now scheduled to ship from the Los Angeles based company to as far away as New York City and projects are being considered at all points in between.

This dramatic growth in the modular elevator market is despite the outbreak of the Covid-19 virus for many reasons. First, modular elevators set in less than a day. Then they are started up in less than a week in most cases. That means fewer people coming and going from the construction job-site, potentially meaning less spread. This contrasts with the old way elevators have been built. That method requires a steady stream of workers showing up for months at a time and working closely together.

With conventional elevators, a hoistway is constructed first, and then all the components are shipped to the job-site and installed. This can be a painstaking and dangerous process as it all takes place in a cramped hoistway. Now with social distancing a concern, the troop of elevator mechanics, construction workers and helpers required for the conventional method may mean a higher risk for spread.

Second, the modular elevator is manufactured in a controlled environment. Safety protocols can be employed easily That is not the case at most project sites. Social distancing and sanitizing the work area can be easily managed. An additional plus of the factory controlled environment is that there is increased elevator and hoistway quality. The manufactured hoistway is a tough steel frame, sheathed in drywall. All of the elevator components are already installed in a controlled environment. They arrive at the project location, are craned into place, and then started up when power is available.

Lastly, project completion overall is much faster when modular is used. It takes the elevator off the critical path during construction. The job can be completed faster leading to a safer building environment.

All of the benefits makes the sales process more of an education than a high-pressure sales pitch. According to Vice President of Sales, Hugo Beltran “The product is perfect for the times in which we are living. They are high-quality commercial elevators set and started up faster than conventional elevators. This means fewer people at the job-site. That makes modular elevators from MEM greener, safer and smarter.”

He went on to say that education on the benefits is made easier due to the competitive pricing. “We are being selected as the elevator solution by our clients because of the investment. It is a better manufactured, higher quality product in line with general elevator pricing and the hoistway is included.”

At the newly enlarged production facility MEM produces elevators from simple ADA compliant models to freight elevators. They are routinely sold for several types of buildings including educational, hospitality, healthcare, multi-family, commercial, storage and parking structures. For more information on MEM go to at modualrelevator.com. See the article MEM Doubles Factory here.

I usually spend hours, if not days, uncovering research about elevators and looking for interesting and useful facts and figures to post in my blog. I research, work and write several times a month hoping to enlighten the reader and maybe make you think or at least smile. I really like doing that because I know elevators are a very interesting subject; so simple yet complex and full of fun details that fascinate.

Also, those in the elevator industry love to gather information and pass it on so I have a great, knowledgeable audience. This combination of smart people and facts can lead to new perspectives or different ways of thinking about the largest moving object in a building.

I also love uncovering the history of elevators, the modular business, construction and manufacturing as subject matter or as a springboard into the elevator industry. But, every once in a while someone does it a little bit better than I do. So rather than trying to copy what was done, it would be better to just post it as is. Below is one such example of a short, concise history that is better than I could have cobbled together.

You can quibble with some of the details if you are in an argumentative mood or choose to believe the romanticized version of the Otis legend, but on the whole this video, although abbreviated, is well researched and correct. The History Guy does a great job in all the videos he produces and I would recommend you poke around a bit on his YouTube page after you watch the video about your favorite mode of vertical transportation. You will find something that interests you for sure.

The video is informative and the format is designed for a broad audience so it is kept short, and as a result the History Guy did not have the time to get in depth about the future of vertical transportation. And as we all know for any low or mid-rise building modular elevators are the future.

If you want more information on that or would like to see one placed you can watch our YouTube video too. Really a fully installed elevator in a couple of hours???? Absolutely true and astounding to see.

Of course for more info you can click the button below and get a Fast Track quote on how much a modular unit would be for your next project. You can also contact us any time for information about MEM or modular elevators.

We have a pretty interesting history too…”A history that deserves to be remembered!”

Stadium Chooses Modular Elevator – Elevators are a crucial part of any stadium and part of any good stadium design. Depending on the size, layout and capacity of the venue, anywhere from one to ten elevators or more may be needed. The purpose of the stadium elevator is to provide everyone unencumbered access, assist with foot traffic concerns and to meet American Disabilities Act (ADA) compliance. For instance the renovation to the venerable Dodger Stadium this past year added five new elevators to the existing two, significantly increasing accessibility.

To ensure access, elevators continue to be the best solution for vertical transportation needs. However, that solution comes with a myriad of problems when a project is in the construction phase if traditional or conventional elevators are utilized.

To alleviate problems with the elevator hoistway construction, component installation and then start up and adjustment the better alternative is a modular elevator. It is a conventional elevator built and installed in an unconventional way and it is the best alternative for any mid or low rise project. Instead of a cumbersome three-phase process where the shaft is built first, elevator is assembled inside second, and then it is turned on and adjusted, the first two steps are done completely in a factory. The elevator arrives as a finished product ready to be placed by a crane.

Most stadium elevators fall into the low and mid rise category, modular (like the one pictured) is the perfect solution.

The unique manufacturing process makes modular a better alternative for the following reasons:

In the stadium project shown, the modular elevator demonstrates its flexibility by being placed in an open area left specifically for the elevator. That was the best choice in this situation, however the modular elevator can be placed at anytime in the building process. Sometimes it get placed first and then built around. Other times it is the last piece of the building puzzle. We will help you decide what is best for your particular project.

Modular elevators can also be placed next to an existing structure or stadium grandstands or inside a building depending on the need. One of the most popular uses regarding stadiums is to retrofit our elevator to gain access to a press box or higher level of seating. However, as pictured modular is perfect for new stadium construction as well.

Practically there is no other alternative for stadiums other than to have elevators installed for access and compliance. So why not use a proven system that alleviates so many of the headaches associated with elevators in construction projects.

If you have a stadium or other building that needs a quality, commercial elevator just click the button below for a Fast Track budget number and find out like our other partners that we are quality elevators taking you to a higher level.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.