There is an old adage especially used in politics to not punch down, especially when it comes to an adversary. You end up making yourself look as small as the competition. I generally stick to that piece of advice. But, then you run into a problem. If the purpose of this blog is to truly educate the public then comparing modular elevators, one company to the others must be done.

Especially when there is such a disparity between the various manufacturers conclusions must be drawn. So I am going to stick with facts as best I can as they are and let you, the consumer draw the conclusions. By the end we will answer the question, who has the best solution for low and mid-rise vertical transportation.

When comparing modular elevators we should have a reasonable and largely unbiased way to make the examination. As stated in a previous post, it really can’t be about the elevator components themselves as they are generally the same in all elevators. We however can compare items manufactured by the companies, the experience that each brings to the table and overall quality.

Let’s begin with items that are not bought from another source but manufactured by the modular elevator companies themselves. Those are in general terms the hoistway and the elevator cab. Often the platform and sling are also manufactured and a few ancillary parts such as hydraulic tanks can be produced as well, but for this article’s purposes let’s stick with the two most crucial and identifiable items the hoistway and cab.

At first blush one would think there is little to compare after all modular hoistways are very similar. In most cases tough 4X4 steel tubing is used for the structure and it is wrapped in drywall. Either one layer is used inside and out or to increase the overall fire rating a second layer can be added. But, when you dig deeper a different picture emerges. First, the sheetrock or drywall used is much different company to company. As modular elevators are by design intended to be put in at anytime during the construction process, it is not unusual for the hoistway produced to sit while other construction is going on around the shaft.

That means that in some locations and with no power for climate control, mold and mildew can pop up inside the shaft especially in more humid areas of North America. One company, Modular Elevator Manufacturing (MEM) provides mold resistant drywall inside and out standard. That mitigates this issue. There is no up charge or hidden cost. The pricing and what is provided is clear and part of any cost estimate. Other companies do not provide mold resistant drywall standard inside and out and that can lead to ecological problems you don’t want to face.

Secondarily, the layout of the hoistway steel is dramatically different one company to the next. Experience has taught the engineers that work with MEM, elevator technicians and high-skilled production workers the value of making improvements to the design. They have been making them methodically over a longer period of time than the competitors as a company. There is no jerry-rigging job to job, but consistent, studied, planned and approved improvements. With MEM your project will never be an experiment in problem solving, but a finished product that has been consistently improved over time.

Due to MEM experience, improvement to the stability and longevity have been built in.

If you thought there is a difference in the hoistway, the real difference shows up in the elevator cab construction. That is because MEM is the only modular elevator company that produces their own Galvaneal cab. Galvaneal is the preferred material for professional construction and commercial quality elevator cabs in most cases. It is tough, durable, sustainable and the industry standard.

However, if cheap and potentially flimsy are your goals you can find companies that make their cabs out of particle board; but watch out! If you have ever owned cheap particle board furniture you know what happens when it gets wet. It tends to mold, swell or crumble (or sometimes all three). You will never have that problem with an MEM cab. Also, if the specs call for a metal cab, MEM is the solution that can meet your needs best. A word of warning, sometimes a bid from a company can contain a wooden cab despite a metal one being called out in the specs. This can be a common deception. Always be clear about what you are getting before you buy.

If the company does not make Galvaneal cabs, they often have to buy a cab from another company and then shoehorn it into the hoistway. This obviously drives up the cost. A secondary issue is that if they are buying a cab from an outside company the cab in question may have trouble fitting properly on the rails creating a poorly moving or loud elevator ride.

See, modular is by design produced in a factory setting with specific jigs and templates. Buying a major component like a cab can be problematic if produced outside of the factory. This is due to the outside cab company not use the same jigs and templates as the modular company. This can create a sometimes sloppy and unacceptable fit.

The need for experience can never be overstated and having neophytes making or selling you an elevator is potentially an enormous mistake. Elevators, need I remind people, are serious. They are costly, have thousands of parts and if they are improperly built they can be dangerous to the riding public. They are the largest and most complex moving object in a building. Knowing next to nothing about elevators, but then selling them anyway is not cute or adorable. It can be a hazard that can cost time, money and potentially cause injuries. But, that is exactly what you can get if you choose to call the wrong modular elevator company for a bid or project.

Feel free to check out MEM. It is more that encouraged because MEM has decades of actual experience from top to bottom in the organization. There are many experienced and licensed professionals that will help you through the buying process to setting and installing.

If you are doing your homework you know that some modular companies have limited experience in the area of sales and manufacturing elevators. Factually, one modular company routinely touts 20 years of experience, even on their website. Just a little research shows this to not be completely true. The company in question is reported to have produced its first elevator in 2011. That is a far cry from decades of experience, but is representative of the candor you may find when looking for quality you can trust.

But, besides possibly telling tales out of school, what difference does it all that make anyway? In truth a big difference. Over the years, experience has taught MEM to make an easy to use template and supply anchor bolts as part of the package. This makes installing the elevator much easier, faster and within the engineering requirements. Experience:

Quality is sometimes hard to define and long-term in nature regarding elevators, but again experience is the guide. An elevator is a long-term investment in any building project so it only makes sense to use a company and product that has the longest track record of success. As MEM has been around longer and with a real commitment to quality. As a result, it makes sense to consider them first when comparing modular elevators.

One company has such low production values that elevators have shipped with significant quality issues even before they are installed. Hydraulic tank failure, poor attention to detail, wiring issues have all been reported numerous times from independent elevator technicians. And that is the tip of the iceberg, it is completely true that an elevator jack weighing several hundred pounds literally fell out of one of their hoistways when suspended above a building. Crazy, dangerous, true.

Some companies just don’t have the commitment to quality that MEM has. This can been seen regarding missing parts, poorly assembled components, damaged items in production and promises made but not kept.

We fight that kind of inconsistency and complacency in production and delivery so the whole modular industry won’t get a black eye. MEM has developed a check list to track issues before they show up on the job site not after. This way we know we are providing a great product to you before it ships. Truth, not punching down.

First, we all know that modular elevators are the future because they are the best choice for any low or mid-rise project new or retrofit. They have many advantages over conventional elevators and if you would like a fast review of those you can read more here. But you must be careful and smart when researching which modular company you should deal with. So keep in mind the following and look for a company that is:

In other words look for Modular Elevator Manufacturing (MEM) the overwhelming choice for any low or mid-rise building project. If you want a no obligation assessment and quote just click the link below. It will ask a few questions so we can get started and you can start your path to a true quality commercial elevator.

Apples and Oranges Comparing Elevator Solutions – Modular Versus Traditional. In the construction industry there is a great desire to save time and money while simultaneously providing a high-quality, finished product for the client. This task is complicated immensely when multi-story projects are slated and an elevator is involved. It seems that no one in the elevator business wants to make it easy for general contractors, architects, project managers or building owners to make a clear decision about what elevator company or vertical transportation option would be the best solution.

To combat this problem specs have been developed over time for various elevator footprints, capacities and travel, based on the needs or use of the building. But this does not work! Being in the elevator business, I can tell you most of the time specs are routinely ignored by large elevator companies. At least until after the pricing has been submitted and the decision has been made.

The usual process involves the salesperson picking the closest standard product and then filling the proposal with “if, ands and wherefores” that will be addressed at a later date once a choice is made. Only then the specs are examined and leverage is brought to bear to force time sensitive decisions about the product selected.

This all too familiar dance is the reason the elevator industry is so despised in many quarters. One might draw the conclusion that the elevator industry does not want an apples to apples comparison to be made. Preferring, instead, to keep customers in the dark.

At MEM, we do not shy away from an accurate comparison and we will even help with your assessment, whether we are right for your project or not. Another option is to find a reputable elevator consultant that can help with the decision making process.

However, keep reading if you need a broad overview to help you in your assessment and decision making process.

Generally speaking when it comes to quality commercial elevators there are two very broad categories of solutions. Traditional elevators where the hoistway is built on-site and then the various components are pieced together inside once power is on or available. And modular elevators where the whole elevator is produced in a factory setting.

The first thing to know about either category of elevator is that the components are all very similar. After all, if comparing the types of elevators is the goal, there has to be a clear understanding of the quality of the components that make up the elevator.

Believe it or not most elevators contain, relatively, the same components. There are only a handful of companies that actually manufacture all the stuff inside a hoistway. Secondly, elevator components are highly regulated. The bottom line is that elevator to elevator most of the parts (regardless of name plate) are either the exact same or they meet the exact same standards.

Keep that in mind when a sales rep from a traditional elevator company starts talking about components. There is nothing magical or special about them.

The bigger question regarding parts and components is if they are proprietary or not. Avoid elevators with proprietary parts at all costs. Proprietary means that the elevator manufacturer has control over the functioning of the elevator through access to parts and tools. Service is restricted to just that company. This may mean a lower priced elevator up front, but over time you will be at their mercy. Never get an elevator with proprietary parts or for that matter, buy a building with an elevator with proprietary parts inside. You will regret it.

So if parts are not really different, what is the difference between conventional and modular? It is all about the packaging. The traditional elevator comes in crates or on skids and is assembled on-site once the power is turned on. So if you choose a conventional elevator, you really aren’t buying an elevator at all. You are buying boxes of elevator parts that are hammered, screwed and bolted together on-site in a cramped hoistway.

Think of the last car you purchased. Imagine if the dealership dropped off crates filled with parts, boxes full of hardware and most of the necessary tools to assemble your car in your driveway. Then the dealership sent over a couple of technicians on their timetable to assemble the whole mess. You would see this as you look out of your window and would think, “surely this would be easier in the factory!” It would be and so is building an elevator in a factory.

Thank goodness, that is not how the automotive industry works. They deliver a fully functioning, turnkey product that was assembled efficiently and safely in their quality (and climate) controlled facility.

Elevator companies for years have told the little white lie that they are manufacturing elevators. Not true! What they really do is manufacture some elevator parts and buy the rest of the components from different companies. They then ship them all in boxes to hopefully be assembled properly on-site. Good luck.

The major difference between conventional and modular is with modular you are buying an elevator…not boxes of stuff. Modular is manufactured as a finished product in a quality (and climate) controlled environment, not bolted together in a dark shaft at a technicians leisure. It is difficult to quantify, but if you ever rode in an elevator that rattled as it went up…it was more than likely haphazardly assembled in a cramped elevator hoistway and not in a factory.

Also, because modular elevators are usually engineered to be free standing, you get to decide when it arrives and when it is set in place. There are no elevator contractors taking over your site, no storage problems, no additional trades tripping over each other and the timeline becomes yours not an elevator installer’s.

So when comparing traditional and modular remember the following:

By looking at the short list above it is an easy call to make. The overall better choice for any low or mid-rise building project is the unconventional modular elevator manufactured by MEM. This is especially true when the pricing is generally in the same ballpark, but even when the initial investment is higher for modular the scale is still tipped in favor of the modular solution. The plumb and straight hoistway is always in the price of modular so there is that difference when comparing, but beyond that think of the shortened timeline that a modular elevator creates.

As an anecdotal example of the reasoning, while working with a building owner that decided to go modular for the first time in a hotel project, he thanked me for the extra million dollars he was going to make on the project due to the faster elevator placement. He felt the whole timeline was trimmed by six months by using a modular unit meaning faster occupancy. He went on and said that the million did not take into account the reduced general building costs of maintaining a job site over a longer period of time.

Even if initial cost of the modular elevator were higher, the overall cost for the whole project would always be more than made up for. This is especially true in colder climates.

But thinking bigger, there is a huge value to the comfort level with knowing it is a high-quality product due to the tight manufacturing standards and easily inspected process. For instance:

To be clear, there are sometimes when modular is not the solution. As and example they are shipped on the back of a truck. So even though we have produced freight elevators and elevators for medical facilities big enough for hospital beds, there are some special circumstances where we can’t get under a bridge.

Another example is overall tower height. When you get over ten to twelve stories, cost wise conventional is usually the better option, but on balance for most building projects the best solution is always modular and MEM is the place to start.

We are knowledgeable, experienced, helpful and ready to discuss elevators…not sell them. Honestly, they sell themselves our goal is just to educate the construction industry that there is a better alternative when comparing apples to apples or modular versus traditional.

If this blog post has intrigued you at all the process starts with clicking the button below. You will be asked a few general questions and then we will contact you so we can provide a thumbnail price for your next project.

Construction costs regarding steel and lumber are on the rise nationally. So, many are searching for solutions to the problem and modular is considered a fix to help keep construction costs low despite increases. There are other options to consider of course, but one of the solutions is a modular fix. Read below for a larger list of ways builders can save on resources when the price of materials goes up.

According to the Associated Builders and Contractors analysis of the Bureau of Labor Statistics data they report a 73% price rise (January 2020 to January 2021) for softwood lumber. The increase was 3.2% in the same period for fabricated structural metal and a 15.6 increase in iron and steel. Each source for the data you can find differs but, no one can doubt prices are trending up especially for lumber.

The reasons for the increases are varied, but most of the blame resides with, unsurprisingly, Covid. The virus has had a ripple effect on the entire domestics and global economy with tendrils reaching deep into nearly every market. Covid forced furnaces to go cold in the steel industry and the lumber market to misread demand. Not to mention these industries require a hands on production processes. Human contact in facilities was inevitable. This strained and continues to strain the supply chain. Hence prices trend up.

With increased costs a reality, it the falls on the shoulders of the builders to find alternatives to keep costs low. In seminars, conference calls, articles and meetings leaders in the building industry are in search of ways to absorb or cut costs so the rise in materials will not impact bottom line. Here are just a few the thoughts and ideas getting kicked around:

Literal stick-built projects may need to use another material. There are options that are wide-ranging including the use of metal products. Although there is a rise in metal costs it is no where near the rise in cost of lumber overall. Where steel or metal are traditionally used, alternatives can be found. For instance some in the industry are considering using more TPO (thermoplastic polyolefin) roofing where metal panels were the material of choice just months ago.

Materials are a huge cost no doubt, but there are other methods to cut the cost of a project overall. Going completely modular or purchasing some modular components can shrink the manpower and total time needed onsite. As an example because the modular elevator comes installed in a fabricated hoistway, you can take the shaft out build costs completely. A modular elevator comes with a shaft or hoistway. Talk about savings.

General construction costs are lower as well. Regarding the elevator, the total construction time onsite is reduced. Traditional elevators most commonly install at the end of the building project. It can tack on weeks to months of general construction costs! With modular the set of fully installed elevator is usually first step. It takes less than ONE DAY and start up is completed in less than 1 week. So, you tell me…what are the general construction costs for weeks to months? Modular makes sense to save money.

This one is a bit repetitive but, if the project is finished faster, it is more quickly ready for occupancy. When one hotelier commented to me that going modular put a million dollars in his pocket, he wasn’t exaggerating. Can new building practices get you to reaping ROI rewards quicker?

Many builders are rethinking the time period they allow for a quote to remain valid. It is not unusual, depending on the structure, for a quote or bid to have an expiration of 6 months or more. And when deadlines approach they are often waived. When prices for materials are not stable and bounce (especially in an upward direction), it can leave builders holding the bag. Shortening the shelf life of a quote could allow the builder to be more accurate with estimates, thus saving money.

Now is the time to look at the bids and quotes out there on the table. If you have a quote that has matured, but still valid book it before they change their mind. That means with us at MEM! So, lock in lower prices before the prices are changed in the future. It only makes sense. If you have a project that requires an elevator why put it off for prices to possibly increase? That not only applies to elevators. With broad increases expected, now may be the time to set some plans in stone.

The one thing that is absolutely true about the construction industry is that it is resilient. Builders will always find ways to provide an exceptional product at a fair price. Whether a hotel, housing unit, educational facility or commercial property there are solutions!

The invisible hand of economics demands that even the unseen forces like a deadly virus will not stop the building industry or the economy as a whole. Through individual companies big and small, freedom of production and freedom of consumption, the best interest of the market will be fulfilled. The question is, are you willing to embrace some of the new solutions or opportunities getting bandied about?

If you have a project that needs a faster timeline or you have received a quote from us in the past, now is the time to get the package locked in or get new numbers to consider before prices spike. We all know a conventional elevator slows projects down and creates headaches. They also add unforeseen additional costs that are even more damaging to your projects bottom line. Now with MEM elevators you can lock in certainty and do something about material increases. We are modular elevators taking you to a higher level.

Confusing Elevator Talk – In a recent Zoom conference with an architect, a simple question was posed, “Are elevators confusing on purpose?” The question made me stop in my tracks. This is the same thought that crossed my mind many times in doctor’s offices. Just replace the word “elevators” with “medicine”. It made me wonder, has our industry gotten to that point?

I’ll get to my answer in a minute but, first let me give you some context. Just prior to our online meeting my caller had just left another confab with a sales representative from a big elevator company. The salesperson was pressing for answers on a project regarding the elevator. That ball was being tossed between the architect who called me, the building owner and the construction manager. All three had questions before they pulled the trigger.

In the meeting it was discussed that the proposed elevator did not meet all the specs called out in the plans. So the architect had more queries. The owner of the building was fearful of hidden costs regarding the long-term maintenance and proprietary components. Finally the construction manager just wanted to know the particulars of the shaft and project timing. They went into the meeting thinking that they would get straightforward answers and clear their clouded minds.

Instead, none of the questions were answered in any understandable fashion and hence the Zoom call, the question and a little bit of venting.

It took a more than a couple seconds to gather my thoughts. And a few ummmhs to consider what was asked fully.

When my stammering ceased, my answer was an unsurprising yes and no. I went on the explain that of course elevators are confusing but, not on purpose. They are complex machines and usually the largest moving object in any building so very specific terms have been developed over time that means very specific things (here are a few examples). If you are outside of the elevator industry, sometimes those words can be complicated and muddy the conversation.

It is like eavesdropping on a team of doctors pondering possible treatments to an ailment. In all likelihood you would hear words that seem confusing, jargon stuffed paragraphs and three-letter abbreviations that make no sense to the vast majority of people outside of the medical profession. If I had to make a judgement call on healthcare issues based upon the inside discussions of a group physicians, I would most assuredly be confused. I am not a doctor and trust me that’s a good thing. So my limited knowledge would produce a poor outcome. That outcome would be paralysis of thought and real bad decision making.

Elevator chatter can likewise be the same. If you get in a room of elevator consultants, engineers and technicians and listen to what is being said, it would be the dizzying. Inside jokes would fly over your head and technical terms would land on deaf ears.

In the medical example, with a proper best bedside manner it all becomes clear when the doctor emerges from the circle of peers and speaks to the patient…or at least it should. My point is that elevator folks need to remember the audience when they are answering questions and discussing issues. Humility not hubris is needed and clear everyday language is the requirement not inside baseball jargon. This is not because our customers are too stupid understand! They are busy beyond belief with dozens of other building systems to manage and the elevator is just one piece. The burden is on us to clearly communicate.

But yes, elevators are complex in some ways and are confusing. They don’t need to be made confusing.

On the other hand, for years I have had the unenviable task of trying to explain elevators in simple terms. It can be done! The premise of modular elevators is that we can make high-quality commercial elevators easy to understand, purchase, set and start up. This can be hard as we are taking all the engineering of a modular tube-steel hoistway and putting all the elevator components inside the hoistway in a factory. Elevator complexity times two.

This manufacturing process must be done with the highest precision and quality assurance. The engineering must be spot on and the product must leave the facility ready to start up once up-righted at the site and the electricity is supplied. All this must be explained plainly and easily.

So, I know elevators can be made easy to understand because at MEM we have the chore of not only explaining the elevator but, the modular hoistway as well. It just seems that some in our industry gain some real pleasure in speaking over peoples heads. That arrogance leads to confusion.

Arrogance may just be the tip of the confusion iceberg however. I am convinced and so are a lot of other people in the industry that make it hard to understand intentionally. The purpose is to confuse the potential customer so selling up is easier.

Everyone that deals with old-fashioned, conventional elevators companies already knows this is at least true in part. What other motive can there be for hiding true costs? Why would they breeze over the obvious purpose of proprietary parts? What is the motivation behind the installation process being so overtly laborious and difficult to comprehend? How can the contract being filled with so many exclusions, ifs, wherefores and seemingly more fine print then a contract from Willy Wonka be explained?

One answer may lie in the words of the English philosopher and statesman who among other things developed the scientific method – Sir Francis Bacon. He is credited with saying that “Knowledge is power.” Unfortunately, there is a thought that withholding that knowledge from people will produce control and ultimately wealth. This is not a new notion.

The phrase “Knowledge is power” actually predates Bacon by centuries and contains a darker tone.

“Knowledge is power and it can command obedience. A man of knowledge during his lifetime can make people obey and follow him and he is praised and venerated after his death. Remember that knowledge is a ruler and wealth is its subject.”

Imam Ali – Nahj Al-Balagha (The Way of Eloquence) – Saying 147.5

That quote seems to be the credo of many in the elevator business. If confusion can reign and information withheld, those holding the knowledge can exploit those who don’t have it. Let me say as loudly as possible this is not necessarily a scheme or plot of an evil genius. It is an observation of human behavior. If you need an elevator, only a few have the knowledge to help and they are in control…until the advent of the modular elevator. By breaking away from the old, outmoded way producing and distributing elevators, we changed the way we talk about them as well.

So, there is an option if you have ever felt like asking the question, “Are elevators confusing on purpose?” and you are tired of confusing elevator talk. If you are not getting clear concise answers, contact us.

MEM has a dedicated force of sales representatives that are more knowledgeable than any other. We love selling elevators, but equally we love explaining them and answering questions. It is what we do; we honestly assess your needs, answer your questions and give you information in a way that will be less painful than a trip to the doctor’s office. If you have a project in mind, just click the button below to get started.

When you get over a couple of stories in a building project a man lift or construction elevator becomes a reality. Numbers bear it out even if it is a requirement based on number of stories. The need is there due to the cost of having a construction team without one tromping up and down stairs all day. Workers are simply less productive, so although the cost is often hidden in hours lost by using a staircase, it is real and real expensive.

But, then you have the added cost to your project for the temporary elevator, plus availability, the set up and inevitable delays. It seems you are either paying too much for the savings if you get one or you simply don’t have a construction elevator onsite at all because for a low or mid-rise project it seems cost prohibitive. So, here’s the question: Why use a temporary construction elevator at all when a permanent modular elevator could be used instead?

It makes perfect sense. A commercial quality, modular elevator can be placed and turned on when electricity is available at the jobsite. When construction is finished, it becomes the permanent elevator.

Now before I get started, let me say up front that this is not the perfect solution for every job. If your desired use is not a low or mid-rise project it is probably not a good fit. We are simply not the best solution for high-rises.

Also, if you are wanting to move tons of palatized materials, likewise we are not a match either. Elevators designed for passenger use usually have a capacity of between 2000lbs and 5000lbs. We, of course, can make elevators that have a huge capacity weight-wise, but the cost would outstrip the benefit once the building is opened.

In addition, passenger elevators are limited in size generally. First, you have the cab size. We can make elevators with a cab big enough for a hospital bed (the only limitation is getting elevators under the overpasses on a flatbed truck). But then you have the door issue as well. Usually, passenger elevators have door openings of 36 or 42 inches, although some can be wider. Keep in mind the door opening does not extend across the entire elevator cab. So, if you want to take items to the top floor larger than the cab or the door opening our elevator is not the best way.

There are plenty of other solutions that do not involve an elevator at all if moving big, heavy items is needed. But in most construction scenarios we are the solution or at least worthy of consideration.

I like to say that this blog is designed to be informational and not just a sales pitch. The above is exhibit A of just that. Shoehorning us into a project where it is not a solution makes no sense and damages our credibility. It also damages the credibility of the modular concept overall. We can think outside of the box, and have even made round pegs fit into square holes (see this corner post project) but, modular is not always the best solution.

However, in the majority of construction projects, at the low and mid-rise level we are the solution. This is especially true if you are looking to cut costs regarding the use of a temporary elevator during the construction phase.

In other words, if moving men, tools and some materials is needed on building site, that role could be filled by the modular elevator quite easily and at minimal additional costs.

So, when you start looking at your construction schedule and logistics think about the elevator first. This is not an earthshattering thought. It is common practice for the hoistway or hoistways to be the first item on the drawing board along with stairs. But, here’s the change… don’t think just hoistway. Think fully installed elevator.

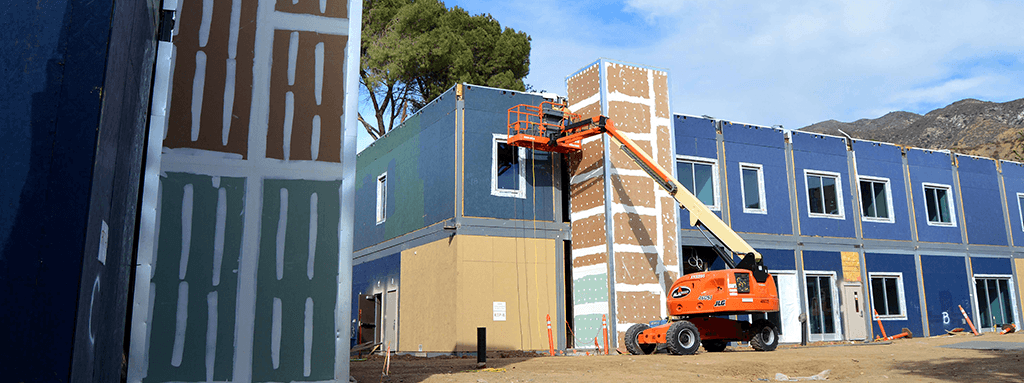

MEM elevators are the hoistways and fully installed elevator. They are a steel shaft wrapped in drywall for fire protection with a complete elevator already inside. The elevator car, rails, wiring, doors and frames are in place when it arrives at the site. In the example video below, that is what you are seeing; a fully installed elevator being set in a building.

Most projects require about 4 hours to get the elevator craned into place.

Then the start up can begin once there is electricity at the building site. Because everything is generally already installed, it takes about a week to get the elevator running. With the inspection, and following the appropriate rules for a construction elevator the modular unit can be used during the building phase.

To make the above possible keep this in mind regarding modular elevators:

Modular elevators (especially from MEM) can help you on the jobsite as both a construction elevator and passenger elevator. It can replace the cost of a construction elevator or it can bring a construction elevator to a job where one was not considered due to cost. It maybe time to consider the benefits of a modular elevator as your construction elevator solution. Click the button below below for a Fast Track quote and to get the process started.

At Modular Elevator Manufacturing we are fond of saying you get the elevator delivered when you want it. But, exactly how does that work? Obviously, you can’t decide on Friday you want an elevator and one pops up on Monday.

There is a process, however it is not laborious and in comparison to stick-built options. It is significantly easier. But, still there are things that must be done in a certain order for you to get a fully installed, commercial quality elevator set on the day you want.

First, a quick explanation as to how modular saves time and helps you with your project. This will help you see the need for the steps we have put into place. With modular construction overall the key is the period between a project being greenlit and the site prep and foundation work being completed. During that time in traditional construction there is some activity, but most of the work is in a holding pattern.

With modular all of the various components are being built during this time period. So when the cement is dry, the crane arrives and the project get’s its elevator and other modular units if any. Not to confuse matters, but it really doesn’t matter to us when you want the elevator at all. In some projects it goes in first, in others last, some in stages. It all comes down to when it is best for you as long as nothing impedes the crane putting it in place.

So now we get to our process. How does it work for your benefit by taking the elevator off the critical path. I hate to be repetitive but, just to remind you it is a fully installed elevator being delivered (car, rails, wiring, doors, etc. all inside the hoistway). In most cases it will be set in 4 hours or less and then started up when there is power. It has to be adjusted, but all that takes less than a week in most cases. Many people still don’t believe it when the unit arrives on time and completely installed. They are use to the old-fashioned way elevators are cobbled together where deadlines are more like guesses.

There are ten general steps from requesting a Fast Track Number to a fully functioning elevator. Some of the steps literally takes place overnight (like getting you a Fast Track Number). Other steps like the design phase takes a bit longer. We can expedite some of the process as well and there are things you can do to move things along. We will get to that, but first below are the standard steps.

You will notice that it takes 16 weeks to produce a high-quality product. That can be shortened, but not significantly. We produce high-quality elevators and are not a company that will rush things and put the riders at risk. Likewise, we will never compromise on safety on the construction site. Some promise an 8 week elevator, well that can cause disaster.

So to shorten the process the most important thing you can do is to get “Step 3” completed as fast as possible and provide us with a general date you would like to have to the elevator delivered. Completing “Step 3” ensures that the engineering and design will begin and providing a prospective date will allow us to plan and block out manufacturing time for you.

Another thing you can do to keep the timeline short and moving forward is being responsive to requests. Sometimes a project can be delayed for a week or more while we wait for a simple signature.

Lastly, make sure your accounting department knows the process. Sometimes internal processes can slow things down.

Remember, our goal is to get you a fully installed elevator when you want it; not too soon or too late. Communication is crucial. We will be proactive in contact with updates. Also, we understand when the delivery date changes. It is the construction business so things happen and pushing out is a reality. We will remain flexible.

To help stay flexible and informed, your primary contact will be the same person through out the entire process. The person that supplied you with the Fast Track Number will be the same person managing the project every step of the way. They are knowledgeable experts in the industry!

Because we have the most experience in the modular elevator world, we can smooth out and anticipate any problems or issues before they occur. This leads to success of your project as a whole and the elevator portion of the building. We consistently accomplish our goal for our clients of an elevator delivered they want it. We want to do the same for you. Let’s get started with a Fast Track Quote today. Click the button below.

SEPT 23, 2020/Westlake, CA – Modular Elevator Manufacturing (MEM) has added new staff to increase capacity and meet growing demand. As the modular elevator manufacturer continues to increase its market share nationwide, a new IT manager, national territory manager, two new elevator technician trainees and elevator technician helper have been added. In addition, a marketing firm with national experience was added to the team.

Duncan McEwan, IT Manager will work to centralize the IT support and system management, providing a more consistent user experience for customers and staff though the improved integration of the IT systems. He previously worked as an IT Administrator for the Television Academy providing support for all of their activities, most notably, the Creative Arts and Primetime Emmy Awards.

This involved supporting the online voting process and hosting IT and audio/visual needs for the various panels that convene each year to vote for categories of Emmy Awards. He also provided the network access, both WiFi and hard wired for the press core at the Emmys Awards, including the WiFi for the Red Carpet. At MEM his experience will improve the customer experience and information flow.

Ken Grider, National Territory Manager brings his commercial and residential construction experience and modular elevator knowledge as well as a proven ability to drive business growth and increase market awareness. More than that, Ken is creative and a strategic thinker with strong communication skills and a strong desire to help customers find the best solution to MEM.

Jesse Ochoa and Jose Perez have been added to increase the ranks of licensed elevator technicians as they complete their training and Jose Galvin has been added as an elevator technician helper. This will ensure that as the demand for modular elevators continues to increase, MEM will maintain the largest and most qualified staff in the modular industry.

Additionally, to assist with the new national effort a St. Louis, Missouri area marketing firm has been engaged. Speiro Communications will help direct the effort to increase an already growing market share. Providing true quality and the most experience in the industry will be the cornerstones going forward.

California based MEM produces elevators from simple ADA compliant models to freight elevators. They are routinely sold in several types of buildings including educational, hospitality, healthcare, multi-family, commercial, storage and parking structures. The elevators are used in retrofit projects as well as new construction. For more information on MEM go to at modualrelevator.com.

If you would like to put the MEM team to work, click the link below to receive a Fast Track quote.

Elevator with a faster ROI. It started out as a simple conversation with a major investor (name withheld intentionally) with a hotel company at a construction job site. I was walking around with a camera around my neck and taking some video. As the crane roared in the background, he leaned over in my general direction and shouted, “Who are you here with?”

I pointed to the modular elevator being suspended by the crane and I said with equal energy back to him, “The elevator company.”

A broad smile crossed his face and he said a curious thing that I was not in the least prepared for, “Thank you.” he shouted.

With an inquisitive look I stammered back, “Your welcome?” He nodded still sporting that wide grin.

It then occurred to me that I had a very rare chance to speak directly to a major investor in the project. We talk constantly to architects, general contractors, elevator contractors, project managers and a whole host of others with various responsibilities, but it was rare to actually be at the job site and speak one on one with an investor. Our paths just don’t cross.

It is not rare that they check up on progress with on site visits, but as the elevator hoistway with all the components pre-installed takes only a couple hours to set it is rare our paths cross. And if he had the time, I would love to ask a few questions about his impressions and what stood out about the modular elevator. So I picked out his SUV…not difficult to do in the construction crew parking lot and camped out near there as I shot more video.

Eventually he appeared from the construction trailer and I asked him for a moment. He said he had a second or two he could spare, so I wasted no time. I introduced myself and asked what he thought.

Now, usually when you see a huge 15 ton object being swung into place at a job site on the end of a crane hook, people take a moment to look up and see what is going on and gaze in amazement. At a recent job in San Diego, faces dotted the windows in an adjacent building so onlookers could to get a peek of the elevator being lifted into place.

I have seen the curious have to be held behind yellow caution tape or with one project, a row of lawn chairs popped up across from a church getting its first elevator. So I imagined the gentleman I was speaking with would talk about how impressive the elevator looked being lifted and placed. I couldn’t have been more wrong.

“Its all about the ROI.” he said. “The return on investment is what excites me most about your product.”

He could tell by my stunned look I needed a further explanation. So he went on to say that with the modular elevator unit in his estimation, nearly 6 month could be trimmed off the total time usually allotted for the build. This significantly reduces the general construction costs. Because he made more money, faster from his perspective, he loved the MEM modular elevator.

He quickly laid out that with modular, while the ground is prepped and the concrete poured, the elevator and hoistway are being produced in a factory. So there is never a delay in hoistway construction. Bad weather doesn’t matter. The elevator can be set any time of year and problems with labor to build the hoistway are non-existent. Everything is done off site.

But beyond that, when the power is available they can use the elevator as a construction elevator. That saves even more money on the project. Finally, he indicated that there is no delay in getting it up and running. There is no need for extra space, extra parking, or having more people onsite stepping over each other. The elevator crew shows up for about a week and voila the elevator functions as intended, not months like usual. The elevator is totally off the critical path and the hotel can be occupied faster.

He summed it all up by saying, “That is why we love your product. An elevator is an elevator to me. Push the button and it goes up. But yours gives a faster return on my investment than any other. And no other elevator can change the timeline on an entire project for the positive.”

With that, as quickly as our impromptu meeting began it ended. He jumped into his SUV and sped off to the next project three states away. However, he gave me a lot to think about. Although an elevator with a faster ROI seemed important before the chance encounter, it now means even more to me.

My hope is investors and building owners that would like to shave time off of a project would click to find out more. They will ultimately realize a faster ROI on a building project if they do. We would love to talk to you about your project and how we can be a part of your solution. Modular Elevator Manufacturing – quality elevators taking you to a higher level.

There is an old adage especially used in politics to not punch down, especially when it comes to an adversary. You end up making yourself look as small as the competition. I generally stick to that piece of advice. But, then you run into a problem. If the purpose of this blog is to truly educate the public then comparing modular elevators, one company to the others must be done.

Especially when there is such a disparity between the various manufacturers conclusions must be drawn. So I am going to stick with facts as best I can as they are and let you, the consumer draw the conclusions. By the end we will answer the question, who has the best solution for low and mid-rise vertical transportation.

When comparing modular elevators we should have a reasonable and largely unbiased way to make the examination. As stated in a previous post, it really can’t be about the elevator components themselves as they are generally the same in all elevators. We however can compare items manufactured by the companies, the experience that each brings to the table and overall quality.

Let’s begin with items that are not bought from another source but manufactured by the modular elevator companies themselves. Those are in general terms the hoistway and the elevator cab. Often the platform and sling are also manufactured and a few ancillary parts such as hydraulic tanks can be produced as well, but for this article’s purposes let’s stick with the two most crucial and identifiable items the hoistway and cab.

At first blush one would think there is little to compare after all modular hoistways are very similar. In most cases tough 4X4 steel tubing is used for the structure and it is wrapped in drywall. Either one layer is used inside and out or to increase the overall fire rating a second layer can be added. But, when you dig deeper a different picture emerges. First, the sheetrock or drywall used is much different company to company. As modular elevators are by design intended to be put in at anytime during the construction process, it is not unusual for the hoistway produced to sit while other construction is going on around the shaft.

That means that in some locations and with no power for climate control, mold and mildew can pop up inside the shaft especially in more humid areas of North America. One company, Modular Elevator Manufacturing (MEM) provides mold resistant drywall inside and out standard. That mitigates this issue. There is no up charge or hidden cost. The pricing and what is provided is clear and part of any cost estimate. Other companies do not provide mold resistant drywall standard inside and out and that can lead to ecological problems you don’t want to face.

Secondarily, the layout of the hoistway steel is dramatically different one company to the next. Experience has taught the engineers that work with MEM, elevator technicians and high-skilled production workers the value of making improvements to the design. They have been making them methodically over a longer period of time than the competitors as a company. There is no jerry-rigging job to job, but consistent, studied, planned and approved improvements. With MEM your project will never be an experiment in problem solving, but a finished product that has been consistently improved over time.

Due to MEM experience, improvement to the stability and longevity have been built in.

If you thought there is a difference in the hoistway, the real difference shows up in the elevator cab construction. That is because MEM is the only modular elevator company that produces their own Galvaneal cab. Galvaneal is the preferred material for professional construction and commercial quality elevator cabs in most cases. It is tough, durable, sustainable and the industry standard.

However, if cheap and potentially flimsy are your goals you can find companies that make their cabs out of particle board; but watch out! If you have ever owned cheap particle board furniture you know what happens when it gets wet. It tends to mold, swell or crumble (or sometimes all three). You will never have that problem with an MEM cab. Also, if the specs call for a metal cab, MEM is the solution that can meet your needs best. A word of warning, sometimes a bid from a company can contain a wooden cab despite a metal one being called out in the specs. This can be a common deception. Always be clear about what you are getting before you buy.

If the company does not make Galvaneal cabs, they often have to buy a cab from another company and then shoehorn it into the hoistway. This obviously drives up the cost. A secondary issue is that if they are buying a cab from an outside company the cab in question may have trouble fitting properly on the rails creating a poorly moving or loud elevator ride.

See, modular is by design produced in a factory setting with specific jigs and templates. Buying a major component like a cab can be problematic if produced outside of the factory. This is due to the outside cab company not use the same jigs and templates as the modular company. This can create a sometimes sloppy and unacceptable fit.

The need for experience can never be overstated and having neophytes making or selling you an elevator is potentially an enormous mistake. Elevators, need I remind people, are serious. They are costly, have thousands of parts and if they are improperly built they can be dangerous to the riding public. They are the largest and most complex moving object in a building. Knowing next to nothing about elevators, but then selling them anyway is not cute or adorable. It can be a hazard that can cost time, money and potentially cause injuries. But, that is exactly what you can get if you choose to call the wrong modular elevator company for a bid or project.

Feel free to check out MEM. It is more that encouraged because MEM has decades of actual experience from top to bottom in the organization. There are many experienced and licensed professionals that will help you through the buying process to setting and installing.

If you are doing your homework you know that some modular companies have limited experience in the area of sales and manufacturing elevators. Factually, one modular company routinely touts 20 years of experience, even on their website. Just a little research shows this to not be completely true. The company in question is reported to have produced its first elevator in 2011. That is a far cry from decades of experience, but is representative of the candor you may find when looking for quality you can trust.

But, besides possibly telling tales out of school, what difference does it all that make anyway? In truth a big difference. Over the years, experience has taught MEM to make an easy to use template and supply anchor bolts as part of the package. This makes installing the elevator much easier, faster and within the engineering requirements. Experience:

Quality is sometimes hard to define and long-term in nature regarding elevators, but again experience is the guide. An elevator is a long-term investment in any building project so it only makes sense to use a company and product that has the longest track record of success. As MEM has been around longer and with a real commitment to quality. As a result, it makes sense to consider them first when comparing modular elevators.

One company has such low production values that elevators have shipped with significant quality issues even before they are installed. Hydraulic tank failure, poor attention to detail, wiring issues have all been reported numerous times from independent elevator technicians. And that is the tip of the iceberg, it is completely true that an elevator jack weighing several hundred pounds literally fell out of one of their hoistways when suspended above a building. Crazy, dangerous, true.

Some companies just don’t have the commitment to quality that MEM has. This can been seen regarding missing parts, poorly assembled components, damaged items in production and promises made but not kept.

We fight that kind of inconsistency and complacency in production and delivery so the whole modular industry won’t get a black eye. MEM has developed a check list to track issues before they show up on the job site not after. This way we know we are providing a great product to you before it ships. Truth, not punching down.

First, we all know that modular elevators are the future because they are the best choice for any low or mid-rise project new or retrofit. They have many advantages over conventional elevators and if you would like a fast review of those you can read more here. But you must be careful and smart when researching which modular company you should deal with. So keep in mind the following and look for a company that:

In other words look for Modular Elevator Manufacturing (MEM) the overwhelming choice for any low or mid-rise building project. If you want a no obligation assessment and quote just click the link below. It will ask a few questions so we can get started and you can start your path to a true quality commercial elevator.

Apples and Oranges Comparing Elevator Solutions – Modular Versus Traditional. In the construction industry there is a great desire to save time and money while simultaneously providing a high-quality, finished product for the client. This task is complicated immensely when multi-story projects are slated and an elevator is involved. It seems that no one in the elevator business wants to make it easy for general contractors, architects, project managers or building owners to make a clear decision about what elevator company or vertical transportation option would be the best solution.

To combat this problem specs have been developed over time for various elevator footprints, capacities and travel, based on the needs or use of the building. But this does not work! Being in the elevator business, I can tell you most of the time specs are routinely ignored by large elevator companies. At least until after the pricing has been submitted and the decision has been made.

The usual process involves the salesperson picking the closest standard product and then filling the proposal with “if, ands and wherefores” that will be addressed at a later date once a choice is made. Only then the specs are examined and leverage is brought to bear to force time sensitive decisions about the product selected.

This all too familiar dance is the reason the elevator industry is so despised in many quarters. One might draw the conclusion that the elevator industry does not want an apples to apples comparison to be made. Preferring, instead, to keep customers in the dark.

At MEM, we do not shy away from an accurate comparison and we will even help with your assessment, whether we are right for your project or not. Another option is to find a reputable elevator consultant that can help with the decision making process.

However, keep reading if you need a broad overview to help you in your assessment and decision making process.

Generally speaking when it comes to quality commercial elevators there are two very broad categories of solutions. Traditional elevators where the hoistway is built on-site and then the various components are pieced together inside once power is on or available. And modular elevators where the whole elevator is produced in a factory setting.

The first thing to know about either category of elevator is that the components are all very similar. After all, if comparing the types of elevators is the goal, there has to be a clear understanding of the quality of the components that make up the elevator.

Believe it or not most elevators contain, relatively, the same components. There are only a handful of companies that actually manufacture all the stuff inside a hoistway. Secondly, elevator components are highly regulated. The bottom line is that elevator to elevator most of the parts (regardless of name plate) are either the exact same or they meet the exact same standards.

Keep that in mind when a sales rep from a traditional elevator company starts talking about components. There is nothing magical or special about them.

The bigger question regarding parts and components is if they are proprietary or not. Avoid elevators with proprietary parts at all costs. Proprietary means that the elevator manufacturer has control over the functioning of the elevator through access to parts and tools. Service is restricted to just that company. This may mean a lower priced elevator up front, but over time you will be at their mercy. Never get an elevator with proprietary parts or for that matter, buy a building with an elevator with proprietary parts inside. You will regret it.

So if parts are not really different, what is the difference between conventional and modular? It is all about the packaging. The traditional elevator comes in crates or on skids and is assembled on-site once the power is turned on. So when you choose a conventional elevator, you really aren’t buying an elevator at all. You are buying boxes of elevator parts that are hammered, screwed and bolted together on-site in a cramped hoistway.

Think of the last car you purchased. Imagine if the dealership dropped off crates filled with parts, boxes full of hardware and most of the necessary tools to assemble your car in your driveway. Then the dealership sent over a couple of technicians to assemble the whole mess. You would see this as you look out of your window on to the now worksite and would think, “surely this would be easier in the factory!”

Thank goodness, that is not how the automotive industry works. They deliver a fully functioning, turnkey product that was assembled efficiently and safely in their quality (and climate) controlled facility.

Elevator companies for years have told the little white lie that they are manufacturing elevators. Not true! What they really do is manufacture some elevator parts and buy the rest of the components from different companies. They then ship them all in boxes to hopefully be assembled properly on-site. Good luck.

The major difference between conventional and modular is with modular you are buying an elevator…not boxes of stuff. Modular is manufactured as a finished product in a quality (and climate) controlled environment, not bolted together in a dark shaft at a technicians leisure. It is difficult to quantify, but if you ever rode in an elevator that rattled as it went up…it was more than likely haphazardly assembled in a cramped elevator hoistway and not in a factory.

Also, because modular elevators are engineered to be free standing, you get to decide when it arrives and when it is set in place. There are no elevator contractors taking over your site, no storage problems, no additional trades tripping over each other and the timeline becomes your’s not an elevator installer’s.

So when comparing traditional and modular remember the following:

By looking at the short list above it is an easy call to make. The overall better choice for any low or mid-rise building project is the unconventional modular elevator manufactured by MEM. This is especially true when the pricing is generally in the same ballpark, but even when the initial investment is higher for modular the scale is still tipped in favor of the modular solution. The plumb and straight hoistway is always in the price of modular so there is that difference when comparing, but beyond that think of the shortened timeline that a modular elevator creates.

As an anecdotal example of the reasoning, while working with a building owner that decided to go modular for the first time in a hotel project, he thanked me for the extra million dollars he was going to make on the project due to the faster elevator placement. He felt the whole timeline was trimmed by six months by using a modular unit meaning faster occupancy. He went on and said that the million did not take into account the reduced general building costs of maintaining a job site over a longer period of time.

Even if initial cost of the modular elevator were higher, the overall cost for the whole project would always be more than made up for. This is especially true in colder climates.

But thinking bigger, there is a huge value to the comfort level with knowing it is a high-quality product due to the tight manufacturing standards and easily inspected process. For instance:

To be clear, there are sometimes when modular is not the solution. As and example they are shipped on the back of a truck. So even though we have produced freight elevators and elevators for medical facilities big enough for hospital beds, there are some special circumstances where we can’t get under a bridge.

Another example is overall tower height. When you get over ten to twelve stories, cost wise conventional is usually the better option, but on balance for most building projects the best solution is always modular and MEM is the place to start.

We are knowledgeable, experienced, helpful and ready to discuss elevators…not sell them. Honestly, they sell themselves our goal is just to educate the construction industry that there is a better alternative when comparing apples to apples or modular versus traditional.

If this blog post has intrigued you at all the process starts with clicking the button below. You will be asked a few general questions and then we will contact you so we can provide a thumbnail price for your next project.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.