MEM Cuts Costs as Interest Rates Rise/ Interest rates are on a roller coaster ride and that roller coaster is heading up. This is a very real, and can be a very damaging problem for the US economy and the construction industry. As the chart below demonstrates the march higher began prior to April of 2022 and continues to this day. The purpose is to slow inflation to around 2% by putting downward pressure on economic activity through Federal Reserve rate hikes. In other words if money becomes too expensive, then industries such as construction will slow. The economy does not shift at a whim especially when all the forces are aligned for inflation at this time regardless of Fed policy. The point is that this maybe a long trend and not just a blip. Inflation has been very sticky and continues to be.

So what can be done in the construction industry to combat high interest rates that maybe here for sometime? Borrow less. Our industry engages in long-term commitments and obligations with slim margins. That applies more pressure as we build, meet payroll and see operating costs explode as simultaneously financing those costs increase. Suddenly, we grasp for every potential savings available by trimming general costs and seeking alternatives.

The right alternative is a commercial quality elevator that has a long-term history of success and that can replace the need for a construction elevator on the jobsite. By consolidating the tasks of a permanent elevator and a construction hoist, costs can be significantly reduced. But, only an elevator fully installed at the beginning of the project and ready for start up early on can meet the need.

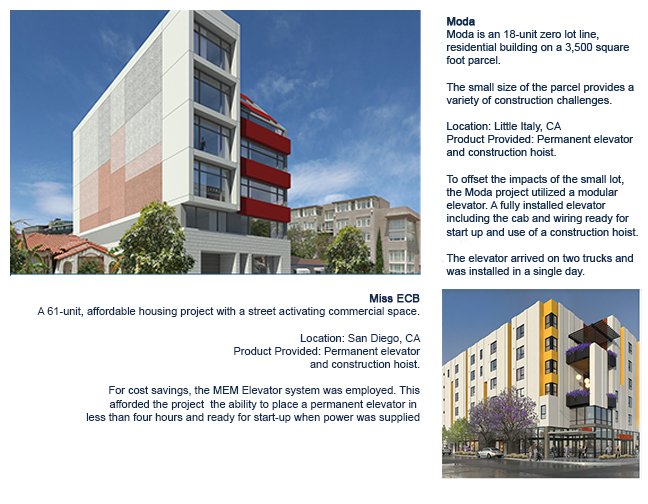

The MEM Elevator System can cuts costs as interest rates and inflation holds firm. Below are just two recent projects that we just finished installing where the permanent elevator doubled as the construction hoist. Not having to employ a construction elevator can reduce costs immensely. This option is not just a way to save during inflationary times, but just smart business.

In both cases the elevator unit or MEM System was placed early in the project. The system is designed to be self-supporting, so it is placed and awaits power, set up and inspection. Placing the fully installed elevator takes less than four hours and the set up portion of the project is usually less than a week in total hours. This makes it not only plausible to save significantly, but a certainty of reducing costs.

As you can see from the photo the elevator operates just like any other construction hoist with a set call box for access. We also go to great lengths to protection the cab interior. Protective panels and wraps are in place during the build. You can also see that it is not a project dependent on any one type of construction method. the MEM System is at home in modular construction to stick built applications.

Additional project savings are due to fact that the MEM Elevator System arrives with the elevator fully installed in the factory produced hoistway. This includes elevator doors and frames. That means no call backs on tape and mud crews, painters and flooring contractors. It is estimated that $40,000 per elevator opening can be saved on most jobs.

If you want to find out more about how choosing the right elevator cuts costs click below. You can either get a thumbnail budget number for the MEM System for your next project or, your can schedule a live virtual tour. During the tour we will pull back the curtain, so you can see how we produce the best elevator solution for all mid and low-rise applications.

Well our full name is Modular Elevator Manufacturing (MEM). We have been in the modular and elevator business for around thirty years and as a result the modular industry is very important to us. We see modular as more than just another way to build. It is a continuing and growing methodology that has forced needed change into the construction industry and elevator industry. It has challenged the status quo with better, smarter, safer and faster ways of producing everything from homes to commercial buildings. This approach has resulted in a revolution that we are proud to be part of where there is more accountability and better processes.

For instance with the MEM Elevator System a fully-installed, commercial elevator is placed in hours and started up in a week. It is incredible and something traditional construction cannot accomplish. Our high-quality system goes in so fast that it is often used as the construction hoist to save even more money on projects.

With that said, leading the charge in the revolution towards better building is the Modular Building Institute (MBI). No doubt as they say, they are “the voice of commercial modular construction”! Their mission is to expand the use of offsite and modular construction through innovative construction practices, outreach and education. They do a fantastic job at fulfilling that mission.

So, if you are a modular producer in the construction industry you should be a part of that organization. We are at Modular Elevator Manufacturing. But more than that if you have any questions about modular, MBI and MEM regarding elevators are experts.

To show off a little bit each year MBI has an annual convention called appropriately the World of Modular. This year it is in San Antonio, Texas – April 25-28, 2022. So, if you are not a modular company but are the least bit curious about the modular industry, I would highly recommend attendance. You will find the leaders of the modular business there discussing alternatives to conventional construction and how modular building continues to grow and change the way projects are completed. It is a place to network, exchange ideas, learn from experts and discuss issues.

At MEM we see joining MBI or attending World of Modular as the first step in joining a revolution of better building and higher quality practices that is changing the world of construction. We look forward to seeing you at the show. Make sure and stop by booth #4 and discuss the elevator and modular revolution with our national territory manager Ken Grider. He will be able to answer any questions and give you a thumbnail price on the spot.

If you just can’t wait for the show, you can contact us below for a Fast Track Quote. This modular elevator quick quote will give you all the pricing information you need to get started. You can also sign up for a LIVE VIRTUAL TOUR. During the tour of our production facility you will see how we produce the highest quality modular elevator in the industry. You can also ask any questions you would like about MEM and our process.

So for some see you in San Antonio or for others, see online live!

Elevator cuts costs as inflation rises. Inflation is not just a term thrown around by the Wall Street crowd or economists. Inflation is very real, very damaging and turns out not transitory (whatever that means). As the January numbers reveal inflation is with us. And an economy does not shift at a whim especially when the all the forces are aligned for inflation and the social psychology for it has set in. The ripples are felt throughout the nation in every home and every sector.

That is especially true in the construction industry. We are engage in long-term commitments and obligations with slim margins. That puts more pressure as we build, meet payroll and see operating costs explode. Suddenly, we grasp for every potential savings available by trimming general costs and seeking alternatives. Surprisingly, the elevator cuts costs as inflation rises, but only if you choose the right alternative.

The right alternative is a commercial quality elevator that has a long-term history of success and that can replace the need for a construction elevator on the jobsite. By consolidating the tasks of a permanent elevator and a construction hoist, costs can be significantly reduced. But, only an elevator fully installed at the beginning of the project and ready for start up early on can meet the need.

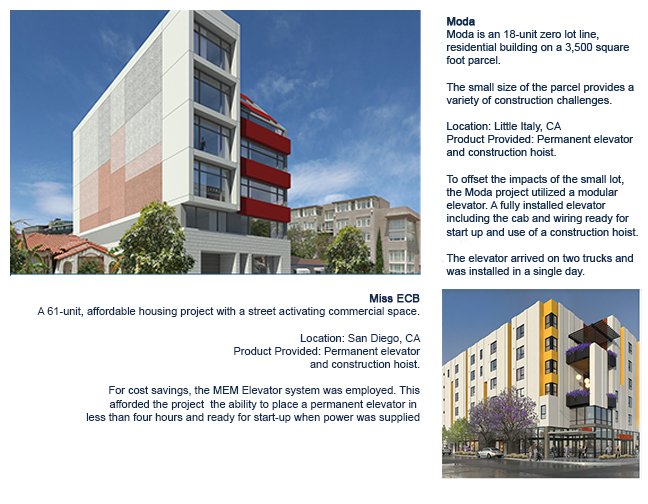

This month’s project spotlight is really several projects, but two in particular that we just finished installing where the permanent elevator doubled as the construction hoist. Not having to employ a construction elevator can reduce costs immensely. This option is not just a way to save during inflationary times, but just smart business.

In both cases the elevator unit or MEM System was in place early in the project. The system can be engineered to be self-supporting, so it is placed and awaits power, set up and inspection. The set up portion of the project is usually less than a week in total hours. This makes it not only plausible to save significantly, but a certainty of reducing costs.

The Miss ECB project fully demonstrates the time and costs savings. As you can see it operates just like any other construction hoist with a set call box for access. Finish protection is key. Protective panels and wraps are in place during the build. You can also see that it is not a project dependent on any one type of construction method. the MEM System is at home in modular construction to stick built applications.

You can see there are two sections as pictured above. They are stackable units that make up the hoistway. The entire process took less than four hours to set. As a result, the fully installed elevator through the MEM System was ready for start up and inspection once power was supplied.

If you want to find out more about how choosing the right elevator cuts costs click below. You can either get a thumbnail budget number for the MEM System for your next project or, your can schedule a live virtual tour. During the tour we will pull back the curtain, so you can see how we produce the best elevator solution for all mid and low-rise applications.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.