Apples and Oranges Comparing Elevator Solutions – Modular Versus Traditional. In the construction industry there is a great desire to save time and money while simultaneously providing a high-quality, finished product for the client. This task is complicated immensely when multi-story projects are slated and an elevator is involved. It seems that no one in the elevator business wants to make it easy for general contractors, architects, project managers or building owners to make a clear decision about what elevator company or vertical transportation option would be the best solution.

To combat this problem specs have been developed over time for various elevator footprints, capacities and travel, based on the needs or use of the building. But this does not work! Being in the elevator business, I can tell you most of the time specs are routinely ignored by large elevator companies. At least until after the pricing has been submitted and the decision has been made.

The usual process involves the salesperson picking the closest standard product and then filling the proposal with “if, ands and wherefores” that will be addressed at a later date once a choice is made. Only then the specs are examined and leverage is brought to bear to force time sensitive decisions about the product selected.

This all too familiar dance is the reason the elevator industry is so despised in many quarters. One might draw the conclusion that the elevator industry does not want an apples to apples comparison to be made. Preferring, instead, to keep customers in the dark.

At MEM, we do not shy away from an accurate comparison and we will even help with your assessment, whether we are right for your project or not. Another option is to find a reputable elevator consultant that can help with the decision making process.

However, keep reading if you need a broad overview to help you in your assessment and decision making process.

Generally speaking when it comes to quality commercial elevators there are two very broad categories of solutions. Traditional elevators where the hoistway is built on-site and then the various components are pieced together inside once power is on or available. And modular elevators where the whole elevator is produced in a factory setting.

The first thing to know about either category of elevator is that the components are all very similar. After all, if comparing the types of elevators is the goal, there has to be a clear understanding of the quality of the components that make up the elevator.

Believe it or not most elevators contain, relatively, the same components. There are only a handful of companies that actually manufacture all the stuff inside a hoistway. Secondly, elevator components are highly regulated. The bottom line is that elevator to elevator most of the parts (regardless of name plate) are either the exact same or they meet the exact same standards.

Keep that in mind when a sales rep from a traditional elevator company starts talking about components. There is nothing magical or special about them.

The bigger question regarding parts and components is if they are proprietary or not. Avoid elevators with proprietary parts at all costs. Proprietary means that the elevator manufacturer has control over the functioning of the elevator through access to parts and tools. Service is restricted to just that company. This may mean a lower priced elevator up front, but over time you will be at their mercy. Never get an elevator with proprietary parts or for that matter, buy a building with an elevator with proprietary parts inside. You will regret it.

So if parts are not really different, what is the difference between conventional and modular? It is all about the packaging. The traditional elevator comes in crates or on skids and is assembled on-site once the power is turned on. So if you choose a conventional elevator, you really aren’t buying an elevator at all. You are buying boxes of elevator parts that are hammered, screwed and bolted together on-site in a cramped hoistway.

Think of the last car you purchased. Imagine if the dealership dropped off crates filled with parts, boxes full of hardware and most of the necessary tools to assemble your car in your driveway. Then the dealership sent over a couple of technicians on their timetable to assemble the whole mess. You would see this as you look out of your window and would think, “surely this would be easier in the factory!” It would be and so is building an elevator in a factory.

Thank goodness, that is not how the automotive industry works. They deliver a fully functioning, turnkey product that was assembled efficiently and safely in their quality (and climate) controlled facility.

Elevator companies for years have told the little white lie that they are manufacturing elevators. Not true! What they really do is manufacture some elevator parts and buy the rest of the components from different companies. They then ship them all in boxes to hopefully be assembled properly on-site. Good luck.

The major difference between conventional and modular is with modular you are buying an elevator…not boxes of stuff. Modular is manufactured as a finished product in a quality (and climate) controlled environment, not bolted together in a dark shaft at a technicians leisure. It is difficult to quantify, but if you ever rode in an elevator that rattled as it went up…it was more than likely haphazardly assembled in a cramped elevator hoistway and not in a factory.

Also, because modular elevators are usually engineered to be free standing, you get to decide when it arrives and when it is set in place. There are no elevator contractors taking over your site, no storage problems, no additional trades tripping over each other and the timeline becomes yours not an elevator installer’s.

So when comparing traditional and modular remember the following:

By looking at the short list above it is an easy call to make. The overall better choice for any low or mid-rise building project is the unconventional modular elevator manufactured by MEM. This is especially true when the pricing is generally in the same ballpark, but even when the initial investment is higher for modular the scale is still tipped in favor of the modular solution. The plumb and straight hoistway is always in the price of modular so there is that difference when comparing, but beyond that think of the shortened timeline that a modular elevator creates.

As an anecdotal example of the reasoning, while working with a building owner that decided to go modular for the first time in a hotel project, he thanked me for the extra million dollars he was going to make on the project due to the faster elevator placement. He felt the whole timeline was trimmed by six months by using a modular unit meaning faster occupancy. He went on and said that the million did not take into account the reduced general building costs of maintaining a job site over a longer period of time.

Even if initial cost of the modular elevator were higher, the overall cost for the whole project would always be more than made up for. This is especially true in colder climates.

But thinking bigger, there is a huge value to the comfort level with knowing it is a high-quality product due to the tight manufacturing standards and easily inspected process. For instance:

To be clear, there are sometimes when modular is not the solution. As and example they are shipped on the back of a truck. So even though we have produced freight elevators and elevators for medical facilities big enough for hospital beds, there are some special circumstances where we can’t get under a bridge.

Another example is overall tower height. When you get over ten to twelve stories, cost wise conventional is usually the better option, but on balance for most building projects the best solution is always modular and MEM is the place to start.

We are knowledgeable, experienced, helpful and ready to discuss elevators…not sell them. Honestly, they sell themselves our goal is just to educate the construction industry that there is a better alternative when comparing apples to apples or modular versus traditional.

If this blog post has intrigued you at all the process starts with clicking the button below. You will be asked a few general questions and then we will contact you so we can provide a thumbnail price for your next project.

Elevator secrets can mean more than you think. If you are in the process of buying an elevator for a building project watch out. Realize you need help! But despite pushing the help button often none is found. The reason is because there are dozens of dirty little elevator secrets the major elevator companies don’t want you to know about.

That should be no surprise. After all the elevator industry is more cloaked in darkness than the Illuminati or the New World Order. They tend to hide what they do and lurk in the fog regarding important items like: costs, timelines and motives. So, in this blog post I will shine some light on just two of the biggest elevator secrets. You will also be given tips on how to shed some much needed light yourself on an industry that desperately needs it.

But first, why do they hide the information? Let me tell you, it is not an evil plot devised by a cat stroking Bond villain. It is a more mundane motive. Money. If you, the consumer, are not given clear factual information, the likelihood is you will make poor decisions regarding vertical transportation. Also, you will become more reliant on the elevator company itself for the limited facts that are available. So your decisions will be made with few and skewed facts and that will ensure you bleed money and they get richer. The result is overall lifetime cost of an elevator becomes much higher than advertised. So let’s get started with just two elevator secrets.

The first elevator secrets is the real profit for the major elevator companies in maintenance. To make money they need to keep you under their thumb regarding the contract. Otis in a recent SEC filings said, “New Equipment and Service, which, for the year ended December 31, 2019, contributed 43 percent and 57 percent of our net sales, and 20 percent and 80 percent of our total segment operating profit, respectively.”

Did you get that? That means is that new equipment or elevator sales while important is no where near as profitable as the maintenance. And to keep the money rolling in, unknowing customers are being pushed into making decisions that increases the profit of the elevator company through the maintenance contract not the elevator itself. How do they do this?

The vast majority of people that ride in an elevator don’t give it a second thought. The doors opens, they walk in, push a button and go up. They do not care about the mechanical means of conveyance at all. But, selling up to a different type of elevator conveyance can make a bigger profit for elevator companies through the maintenance agreement. So…they push specific elevator types that increase the maintenance contract price. This is despite most riders or building owners not caring a wit about how they get from point A to point B.

So, when I personally speak to people that are being oversold on the type of conveyance it makes me a little steamed. Let me be blunt. If you are being sold a traction elevator (the kind with ropes) for a low-rise application you are most likely being oversold. You are more than likely being taken advantage of.

Why? Because the long-term maintenance contract for a 3-stop hydraulic elevator is around $200 per month (depending on where and other factors). For a 3-stop traction it can be $600 or more per month (depending on where and other factors). Need more convincing? Do the math. The lifespan of a typical elevator is 20 years (240 months). With hydraulic maintenance cost around $200 a month, that is $48,000 over the lifespan of the elevator. A traction elevator on the other hand, at $600 a month is approximately $144,000 over the lifetime.

Now you know why they upsell unwitting customers on traction when often it is not needed. They will even discount the initial sales price on traction units to make less upfront as a way to garner longer, more profitable returns. A real quick note, hydraulic elevators are not inferior just less expensive to maintain. Also, this is not a screed against traction units. Sometimes they are needed. We just honestly assess your project and make recommendations rather than selling you up to something you don’t need.

But that is not the end of the elevator secrets and profit motives. When the light bulb goes off and you realize you have been duped. And you are overpaying and try to get out of the contract so you can competitively shop it, you can’t. That is because part of that cheap up front price usually includes proprietary parts in the elevator system. In simple terms, proprietary parts makes it impossible for anyone to maintain it . Of course other than the elevator company you bought it from. You are stuck. The elevator with proprietary parts requires special tools programmed for your specific elevator. There is no advantage to these tools. They are just the keys to a prison you cannot escape from.

There are also lots of other contractual tricks of the trade to keep you locked in as well; like auto-renewals. Auto renewals are common place with almost everything now-a-days. Phone service to online entertainment auto-renews all the time. But elevator maintenance contracts often auto-renew with an annual increase built in. You miss the tiny renewal window, you can’t get out. The contracts are often multi-year (usually 5 years) and are very lopsided in exclusions and other factors.

The second of the dirty little elevator secrets is the major elevator companies don’t really manufacture elevators at all. Well, at least not in the way we generally think of manufacturing. They do produce some components, but in real terms they are bundlers of other companies parts and pieces. They crate them, ship them and screw them together on site. But the elevator is not manufactured at all, and the parts they actually make are limited. Believe it or not elevator companies have admitted that the real “manufacturing” takes place at the jobsite.

Think about it this way, if General Motors only crated up parts and dropped them off at your front door, you would not consider the car to be a manufacturer. That would be a preposterous notion. Then later in cold or heat, rain or snow it would be put together. A mechanic would meander to your house at their leisure and cobble all those parts together in a process that takes months in your driveway. You would laugh out loud if cars were “manufactured” that way. Yet that is what is done regarding elevators.

This truth reveals a couple of realities. The elevators they sell are screwed together with very little supervision, inspection or quality control. They are cobbled together in dark and cramped environs and in all sorts of challenging conditions. Also, the safety and quality of the elevators rests in a single inspection. At the end of the process they’re given a green light or a punch list of code violations to fix. If that one inspector, in one visit misses something, they just do. Also, the code inspector is not necessarily looking for fit and finish, just functionality and code compliance.

Because traditional elevator companies just really gather elevator components from others, then anyone can buy those components and provide a better, truly manufactured solution. That’s what happens with a modular elevator. We purchase the same or comparable parts, and actually manufacture an elevator in a factory. It is much faster, greener and safer.

Inside a modular unit you will find the same parts because there are precious few elevator component producers. Where different parts are used, due to the level of regulation in the elevator industry, they are all high-quality. All must pass muster of regulating agencies and the elevator code. We just produce the product in a much better and smarter way.

What ultimately makes the difference is that modular elevators are actually manufactured in an assembly process. They are not pieced together in less than optimal working conditions. Imagine that! They are inspected daily for fit and finish. They are always plumb and square because checking quality is as easy as walking the factory floor. The units are produced horizontally so inspections are routine and daily.

Also, because it is manufactured you decide when it arrives. It is then shipped and is placed on-site. This ends workplace interruptions and the elevator is no longer holding up other’s work. They free up work space and the elevator is off the project’s critical path.

The set is less than a half a day. The startup less than a week. And get this, the elevator can be used for construction in some cases! A better elevator because the process is better. Same quality components, manufactured smarter.

Below is an honest list of things to look out for on your next elevator purchase. However, it is a bit self-serving. We feel MEM is the best alternative for quality, safety and cost-effective vertical transportation. However, your decision must be made based on facts and below are some to consider. So, look over this info to avoid some of the dirty little elevator secrets. Feel free to challenge us with questions about our process and products:

Finally, consult, challenge and discuss. Biased? We are. But not regarding the conveyance type. We will be honest and fair. On our factory floor you will find hydraulic elevators and even roped hydraulic units as well to meet your needs. Our bias is based upon modular being a better way to produce elevators, not the elevator itself. We will recommend what you need and price anything else you want or have speced in.

If you are curious and would like more information just click the button below. In 24 hours we can produce a thumbnail price for any project. Remember with us there are no secrets! Just straight forward talk from people that care about you and your project. We are highly experienced in the elevator industry and hope you will join the elevator revolution.

Just the Facts on Modular Elevators. I am old enough to remember the classic TV show Dragnet. Sargent Joe Friday played by Jack Webb and his partner Bill Gannon (Harry Morgan) of the Los Angeles Police Department would have a weekly crimefighting adventure.

There were two catch phrases in the show. The first was in the shows open, “The following story is true, the names have been changed to protect the innocent.” And the second and even more famous from Sgt. Friday, “Just the facts ma’am.” In truth the character never really said that at all. He said a much longer version “All we want are the facts, ma’am.” But that aside, “Just the facts.” became as famous as his dry, monotone delivery.

Sometimes we forget the facts are really all we need. Sure I spend some time being creative on the blog and looking for ways for the info to stick, but in reality an elevator purchase needs to be based on facts. This is especially true if the facts are in your favor like in the case of modular elevators and the modular industry as a whole.

So below are just the facts on modular elevators and buildings. Look them over, check out what I am saying and then you can decide if modular is right for your next project.

First, an important definition. Modular construction is, “A process in which a building is constructed off-site, under controlled plant conditions, using the same materials and designing to the same codes and standards as conventionally built facilities – but in about half the time. The buildings are produced in ‘modules’ that, when put together on site, reflect the identical design intent and specifications of the most sophisticated site-built facility – without compromise.” That is from the Modular Building Institute the leading non-profit trade association serving modular construction.

To boil the definition down, modular construction is a combination of modular units (in our case a modular elevator) that results in just as high a quality (if not more so) that you would find in stick-built or site-built projects. The components are the same or better with the only difference being a modular unit is manufactured with more exacting standards, closer scrutiny and more quality control. Yet it is completed much faster.

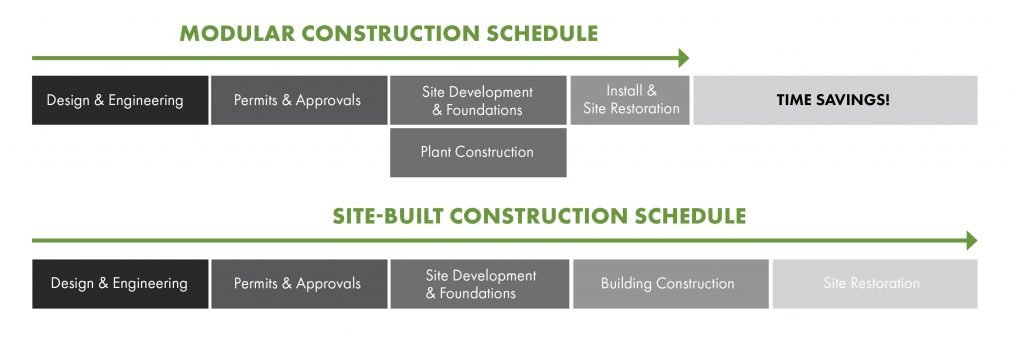

The process overall is faster as a factory can produce a unit faster than it can be built from scratch on site, but faster as well due to the time schedule of the entire build.

While prep work is being done the modules are being completed and readied for shipment.

The modular units can be almost any component of a multi-family buildings, hotel, school, office building or medical facility. Are you building an apartment complex? Modular can produce the entire living space including kitchens and bathrooms, common areas and of course elevators.

Do you need a medical office with a lab, exam rooms, office space, waiting areas and even bathrooms? It can all be modular. If you need to have multiple stories, the elevator from MEM is modular too. This process completely takes the elevator off the critical path.

With that said, let’s look at “Just the Facts.”

Just look at the facts on modular elevators in a way that would make Joe Friday proud and see that modular is the best solution for almost any project. But remember that modular elevators do not need to be in a modular only project! Modular elevators offer great benefits to any building project. To check things out more feel free to ask questions and examine the possibilities. The next step is to contact us for more information or for pricing on a modular solution. Just click the button below for a Fast Track budget number.

Elevator with a faster ROI. It started out as a simple conversation with a major investor (name withheld intentionally) with a hotel company at a construction job site. I was walking around with a camera around my neck and taking some video. As the crane roared in the background, he leaned over in my general direction and shouted, “Who are you here with?”

I pointed to the modular elevator being suspended by the crane and I said with equal energy back to him, “The elevator company.”

A broad smile crossed his face and he said a curious thing that I was not in the least prepared for, “Thank you.” he shouted.

With an inquisitive look I stammered back, “Your welcome?” He nodded still sporting that wide grin.

It then occurred to me that I had a very rare chance to speak directly to a major investor in the project. We talk constantly to architects, general contractors, elevator contractors, project managers and a whole host of others with various responsibilities, but it was rare to actually be at the job site and speak one on one with an investor. Our paths just don’t cross.

It is not rare that they check up on progress with on site visits, but as the elevator hoistway with all the components pre-installed takes only a couple hours to set it is rare our paths cross. And if he had the time, I would love to ask a few questions about his impressions and what stood out about the modular elevator. So I picked out his SUV…not difficult to do in the construction crew parking lot and camped out near there as I shot more video.

Eventually he appeared from the construction trailer and I asked him for a moment. He said he had a second or two he could spare, so I wasted no time. I introduced myself and asked what he thought.

Now, usually when you see a huge 15 ton object being swung into place at a job site on the end of a crane hook, people take a moment to look up and see what is going on and gaze in amazement. At a recent job in San Diego, faces dotted the windows in an adjacent building so onlookers could to get a peek of the elevator being lifted into place.

I have seen the curious have to be held behind yellow caution tape or with one project, a row of lawn chairs popped up across from a church getting its first elevator. So I imagined the gentleman I was speaking with would talk about how impressive the elevator looked being lifted and placed. I couldn’t have been more wrong.

“Its all about the ROI.” he said. “The return on investment is what excites me most about your product.”

He could tell by my stunned look I needed a further explanation. So he went on to say that with the modular elevator unit in his estimation, nearly 6 month could be trimmed off the total time usually allotted for the build. This significantly reduces the general construction costs. Because he made more money, faster from his perspective, he loved the MEM modular elevator.

He quickly laid out that with modular, while the ground is prepped and the concrete poured, the elevator and hoistway are being produced in a factory. So there is never a delay in hoistway construction. Bad weather doesn’t matter. The elevator can be set any time of year and problems with labor to build the hoistway are non-existent. Everything is done off site.

But beyond that, when the power is available they can use the elevator as a construction elevator. That saves even more money on the project. Finally, he indicated that there is no delay in getting it up and running. There is no need for extra space, extra parking, or having more people onsite stepping over each other. The elevator crew shows up for about a week and voila the elevator functions as intended, not months like usual. The elevator is totally off the critical path and the hotel can be occupied faster.

He summed it all up by saying, “That is why we love your product. An elevator is an elevator to me. Push the button and it goes up. But yours gives a faster return on my investment than any other. And no other elevator can change the timeline on an entire project for the positive.”

With that, as quickly as our impromptu meeting began it ended. He jumped into his SUV and sped off to the next project three states away. However, he gave me a lot to think about. Although an elevator with a faster ROI seemed important before the chance encounter, it now means even more to me.

My hope is investors and building owners that would like to shave time off of a project would click to find out more. They will ultimately realize a faster ROI on a building project if they do. We would love to talk to you about your project and how we can be a part of your solution. Modular Elevator Manufacturing – quality elevators taking you to a higher level.

Apples and Oranges Comparing Elevator Solutions – Modular Versus Traditional. In the construction industry there is a great desire to save time and money while simultaneously providing a high-quality, finished product for the client. This task is complicated immensely when multi-story projects are slated and an elevator is involved. It seems that no one in the elevator business wants to make it easy for general contractors, architects, project managers or building owners to make a clear decision about what elevator company or vertical transportation option would be the best solution.

To combat this problem specs have been developed over time for various elevator footprints, capacities and travel, based on the needs or use of the building. But this does not work! Being in the elevator business, I can tell you most of the time specs are routinely ignored by large elevator companies. At least until after the pricing has been submitted and the decision has been made.

The usual process involves the salesperson picking the closest standard product and then filling the proposal with “if, ands and wherefores” that will be addressed at a later date once a choice is made. Only then the specs are examined and leverage is brought to bear to force time sensitive decisions about the product selected.

This all too familiar dance is the reason the elevator industry is so despised in many quarters. One might draw the conclusion that the elevator industry does not want an apples to apples comparison to be made. Preferring, instead, to keep customers in the dark.

At MEM, we do not shy away from an accurate comparison and we will even help with your assessment, whether we are right for your project or not. Another option is to find a reputable elevator consultant that can help with the decision making process.

However, keep reading if you need a broad overview to help you in your assessment and decision making process.

Generally speaking when it comes to quality commercial elevators there are two very broad categories of solutions. Traditional elevators where the hoistway is built on-site and then the various components are pieced together inside once power is on or available. And modular elevators where the whole elevator is produced in a factory setting.

The first thing to know about either category of elevator is that the components are all very similar. After all, if comparing the types of elevators is the goal, there has to be a clear understanding of the quality of the components that make up the elevator.

Believe it or not most elevators contain, relatively, the same components. There are only a handful of companies that actually manufacture all the stuff inside a hoistway. Secondly, elevator components are highly regulated. The bottom line is that elevator to elevator most of the parts (regardless of name plate) are either the exact same or they meet the exact same standards.

Keep that in mind when a sales rep from a traditional elevator company starts talking about components. There is nothing magical or special about them.

The bigger question regarding parts and components is if they are proprietary or not. Avoid elevators with proprietary parts at all costs. Proprietary means that the elevator manufacturer has control over the functioning of the elevator through access to parts and tools. Service is restricted to just that company. This may mean a lower priced elevator up front, but over time you will be at their mercy. Never get an elevator with proprietary parts or for that matter, buy a building with an elevator with proprietary parts inside. You will regret it.

So if parts are not really different, what is the difference between conventional and modular? It is all about the packaging. The traditional elevator comes in crates or on skids and is assembled on-site once the power is turned on. So when you choose a conventional elevator, you really aren’t buying an elevator at all. You are buying boxes of elevator parts that are hammered, screwed and bolted together on-site in a cramped hoistway.

Think of the last car you purchased. Imagine if the dealership dropped off crates filled with parts, boxes full of hardware and most of the necessary tools to assemble your car in your driveway. Then the dealership sent over a couple of technicians to assemble the whole mess. You would see this as you look out of your window on to the now worksite and would think, “surely this would be easier in the factory!”

Thank goodness, that is not how the automotive industry works. They deliver a fully functioning, turnkey product that was assembled efficiently and safely in their quality (and climate) controlled facility.

Elevator companies for years have told the little white lie that they are manufacturing elevators. Not true! What they really do is manufacture some elevator parts and buy the rest of the components from different companies. They then ship them all in boxes to hopefully be assembled properly on-site. Good luck.

The major difference between conventional and modular is with modular you are buying an elevator…not boxes of stuff. Modular is manufactured as a finished product in a quality (and climate) controlled environment, not bolted together in a dark shaft at a technicians leisure. It is difficult to quantify, but if you ever rode in an elevator that rattled as it went up…it was more than likely haphazardly assembled in a cramped elevator hoistway and not in a factory.

Also, because modular elevators are engineered to be free standing, you get to decide when it arrives and when it is set in place. There are no elevator contractors taking over your site, no storage problems, no additional trades tripping over each other and the timeline becomes your’s not an elevator installer’s.

So when comparing traditional and modular remember the following:

By looking at the short list above it is an easy call to make. The overall better choice for any low or mid-rise building project is the unconventional modular elevator manufactured by MEM. This is especially true when the pricing is generally in the same ballpark, but even when the initial investment is higher for modular the scale is still tipped in favor of the modular solution. The plumb and straight hoistway is always in the price of modular so there is that difference when comparing, but beyond that think of the shortened timeline that a modular elevator creates.

As an anecdotal example of the reasoning, while working with a building owner that decided to go modular for the first time in a hotel project, he thanked me for the extra million dollars he was going to make on the project due to the faster elevator placement. He felt the whole timeline was trimmed by six months by using a modular unit meaning faster occupancy. He went on and said that the million did not take into account the reduced general building costs of maintaining a job site over a longer period of time.

Even if initial cost of the modular elevator were higher, the overall cost for the whole project would always be more than made up for. This is especially true in colder climates.

But thinking bigger, there is a huge value to the comfort level with knowing it is a high-quality product due to the tight manufacturing standards and easily inspected process. For instance:

To be clear, there are sometimes when modular is not the solution. As and example they are shipped on the back of a truck. So even though we have produced freight elevators and elevators for medical facilities big enough for hospital beds, there are some special circumstances where we can’t get under a bridge.

Another example is overall tower height. When you get over ten to twelve stories, cost wise conventional is usually the better option, but on balance for most building projects the best solution is always modular and MEM is the place to start.

We are knowledgeable, experienced, helpful and ready to discuss elevators…not sell them. Honestly, they sell themselves our goal is just to educate the construction industry that there is a better alternative when comparing apples to apples or modular versus traditional.

If this blog post has intrigued you at all the process starts with clicking the button below. You will be asked a few general questions and then we will contact you so we can provide a thumbnail price for your next project.

Parking Structures – Modular Elevators Meet Demand – Getting ahead of the curve is important in any construction development or building project. Depending on the particular area and whether you are talking about urban or suburban parking, current trends are moving toward slowing the creation of new parking spaces overall.

Some developers, seeing the possibility of lessening demand, have engineered the possibility of future alternative uses into their parking garage design. Incorporating elements like increased headroom and eliminating the slopped floors, in an effort to create a “flexible use” structure.

They attribute the burgeoning drift to many factors. It is anticipated that the Millennial generation’s reduced desire to own personal vehicles, expanding ride sharing opportunities, increasing focus on public transportation and the promise of self-driving cars will reduce the need for the overall amount of dedicated parking space.

With the current climate, are we on the cusp of urgently needing more parking despite the apparent trends listed above?

With the current outbreak of Covid-19 and its ability to be transmitted in many urban settings and dealing with abuse of public transit by the homeless population, some are re-examining personal transportation as a growing alternative. Public transportation being a germ factory is not new despite this particular strain of the Corona Virus. In the 2008/2009 flu season in London a study was conducted by BMC Infectious Diseases seeking to answer the question, “Is public transport a risk factor for acute respiratory infection?” The answer from the report is, “Recent bus or tram use within five days of symptom onset was associated with an almost six-fold increased risk of consulting for acute respiratory infections.” In a nutshell public transportation seems to increase transmission of viruses.

Really? They needed a study for that? So if reduced public transportation occurs the need for efficient, fast, multi-level parking development in both the urban and suburban areas is or will shortly be needed. Personal car use may rise and parking needs increase.

Keep in mind that with parking, it is not about the overall spaces. It is about where the spaces are. We have plenty of parking spaces in the United States. About 500 million parking spaces (an estimated 3,590 square miles) serve this nation of nearly 326 million people, according to Andy Cohen, co-chief executive of the architecture firm Gensler. He predicts car ownership will peak around 2020 and then start to decline, with more Americans relying on some form of ride-sharing rather than owning their own vehicles by the year 2025.

That was before the Corona Virus stole headlines and people’s lives. Before comfort levels with ride sharing and public transportation began changing. Ride sharing, when analyzing the data, may not be the panacea some had predicted to alleviate long-term parking woes.

Just prior to the virus’ big splashy headlines and justified concerns Bruce Schaller, New York City transportation consultant, saw parking trends differently from others by examining actual car ownership. In his report The New Automobility he concluded that ride sharing has had the opposite effect intended and promised by many. He said, “vehicle ownership has increased in cities where Uber and Lyft are most heavily used…Moreover, the rate of vehicle growth substantially exceeded population growth in five of the eight cities (Boston, Los Angeles, New York, Philadelphia and Chicago).”

Then we get to the virus and it is not just paranoia. Consumer Reports as of May 8th, 2020 acknowledges problems with public transportation, ride sharing and taxi cabs regarding possible transmission. The list of suggested ways to avoid the virus when traveling includes renting a car and then cleaning it yourself, always wearing a mask when driving or riding, requesting only vehicles with glass separating the passengers from drivers or even just packing sneakers and walking. Not very practical. Besides, how do you clean your rented car before driving it?

So with car ownership on the rise despite other alternatives, and virus fears in the forefront of people’s minds, it seems that the need for multi-level parking will not stay flat or decrease but only increase in years to come. Not the predicted result many futurists had hoped for. Now to be clear there is nothing wrong with designing parking space that can be more easily repurposed or adapted in the future. That makes perfect sense especially when considering self-driving cars that can park themselves inches apart requiring less space. Although not a reality today, it may be within the life span of a building project. Forward thinking is important.

However, there will be a new normal when it comes to transportation and thereby parking space. The solution will eventually evolve, but parking will not diminish in the near future. One thing is for sure, the data reveals that car ownership is not subsiding due to ride sharing options and with “social distancing” becoming a standard phrase in our lexicon the mentality of individual travel or traveling as a family unit may become more of the norm, not less as anticipated. You may need more parking solutions faster.

So why is the modular elevator part of the parking solution for projects today and the possible increased projects soon to come? Because they are high-quality, commercial elevators that are durable and have elements specifically designed for parking structures. They also have pre-engineered drawings that can be inserted into plans, manufactured and trucked to the job site and installed.

Modular Elevator Manufacturing removes elevators from the critical path and reduces the headaches of coordination between trades. They are a solution for any low or mid-rise parking structure. If you have a current project for a parking structure or any other building between two and seven stories just click the button below to get a Fast Track budget number.

Modular Elevators Improve Coordination – One thing I am missing right now is baseball. It is my favorite sport and I love to argue stats, history and of course which players are the best of all time. Does the list include Babe Ruth, Ty Cobb, Rogers Hornsby, Ted Williams, Stan Musial, Cy Young, Hank Aaron or all of them? Should we add more recent players like Jeter, A-Rod, Pujols, Trout or Ichiro? And what do you do with Bonds?

Anyway in my estimation, as a baseball purist, I hate the over-weighting of the long-ball in the discussion. Homers are fun to watch, but if time savings were really that important couldn’t they just cut out the overly dramatic trot like they did pitching four balls for an intentional pass? What I really like, instead of guys swing for the fence despite guys having two strikes, is the ballet that takes place on the diamond with a man on first and there is a drive up the middle. Will they turn-two? It takes perfect coordination.

Recently, when placing an elevator at a job site, the point of perfect coordination came up with the project manager. He said that you would not believe how easy the modular elevator made the entire project and how smooth things went because they went with MEM (Modular Elevator Manufacturing).

This was one of those projects that traditional elevator companies shied away from due to the way the shaft was integrated into the design. The project manager was a bit worried as it was his first modular experience. In the past he dealt with the elevator getting installed by a totally different company than the crew that builds the hoistway. This time it was all under the umbrella of MEM and the coordination between hoistway and elevator was perfect.

Because a modular elevator is a manufactured shaft to the dimensions and specifications of the project with the elevator components already installed it must be perfect, and is. In the factory, hand in glove or perfect coordination must and does take place with the buttons, car, rails, wiring and even hall calls factory installed in the horizontal shaft. It is like a well choreographed dance like a double play in baseball and it brings to mind the poem about the best known combo in baseball history a “Trio of bear cubs,” “fleeter than birds.”

Tinker – The hoistway is always perfectly square and plumb unlike their conventional counterparts. It is manufactured out of tough steel with an exterior sheathing and inspected for quality daily. It is the foundation and where everything begins.

To Evers – The hoistway is seamlessly passed down the line. Inside the rail placement is spot on and the car is aligned absolutely correct every time. The use of templates and jigs ensures a smooth ride and tolerances you will never see with a stick-built hoistway. The factory process makes all the components installed with ease and grace. Unlike the conventional process were the elevator car and components are built inside a cramped hoistway.

To Chance – The elevator is sent on to the job site and craned into place in a couple hours ready to be turned on when power is available. Each step is like the perfect double play with the team anticipating each others moves, perfectly timed.

But smooth coordination of the hoistway and elevator into one component is just the tip of the iceberg. In a building project any number of trades has to be managed and directed. It is a massive and costly undertaking to bring together all of the elements. There are dozens of workers and companies to schedule and then coordinate. The manager of this particular project said that the modular elevator helped with this too.

The modular solution removed the elevator from the critical path and simplified the project in a myriad of ways. There was no huge storage space required for crates of elevator parts and mechanic’s tools. No weather concerns delaying the elevator portion of the build. When the elevator was craned into place, it was done. All it needed was power to be brought to life in a matter of days not months.

It makes pulling the right strings easier for the management team, because there are simply fewer strings to pull.

One can argue the merits, qualities and contributions of particular baseball players forever. Who really was the greatest of all time and who deserves to be on a top ten players list? It depends on who you ask. Also what team you pull. Even what position you played growing up on bright summer days in little league or the sandlot has an influence. The stats can be used to bolster one over another and so the argument never really ends. That is part of the charm of America’s pastime. But with modular elevators, the debate is over.

There is only one conclusion. Modular elevators are the absolute best vertical transportation solution for any low to mid-rise project. And there is only one company that has the experience, proven record and quality that makes it the obvious choice. MEM. If you have a project in mind and would like to get a thumbnail number just click the button. You will receive a free, Fast Track quote. There is no doubt it will be a grand slam.

Elevator Babies – It was hard to resist putting a photo of my 6 month-old granddaughter in this article, but I didn’t because that would be way too much bragging and she is too young to be internet famous…at least among our 20,000 readers. But while holding her in my arms I got to thinking about how wonderful being a newborn is. No responsibilities; cry you get food; cry you get changed. Babies get to enjoy a short period in their life when knowing nothing is part of the job description and it is adorable. Sleep, eat, and be held is pretty much the day in a nutshell.

When it comes to the elevator business however, being a neophyte is far from wonderful or adorable. Elevators, need I remind people, are serious. They are costly, have thousands of parts and if they are improperly built they can be dangerous to the riding public. They are the largest and most complex moving component of a building. Knowing nothing about elevators or being elevator babies, but then selling them anyway is not cute or adorable; it is a hazard that can cost time, money and potentially cause injuries. But, that is exactly what you can get if you choose to call the wrong elevator company for a bid or project.

Modular elevators are just the same as stick-built in that regard, especially when you are talking about time and money. We all know that modular building is a wave that has already crashed the old-fashioned way of doing business’ party. It is the best option for any mid-rise building needing vertical transportation and will continue to be in the future. They are simply faster and better. But, if you are not careful, there might be an amateur on the other end of the phone line, selling you up and guessing at rules and regulations. After all when you call a modular elevator company you expect they are the experts in not only modular buildings, but elevators as well, but that is simply not the case if you call the wrong one.

One of the modular companies in particular out there that sells a cheap variety of modular elevator purports to be elevator experts. They are far from it and when you know the facts it can be a bit scary trusting a sales team that has no real experience. When I say no, I mean no. Three out of four of the sales team has a combined total of elevator or modular experience of less than a year. Yes, I said combined. My granddaughter has more experience being a baby than they do individually when it comes to elevators or modular units.

But it doesn’t stop there. The Quality Control Manager and Production Manager had no experience in modular building or elevators before coming to that company. Think about that for a second. The person that is supposed to be checking on quality has never checked for quality in the elevator business. In other words, watch out! Beware! Someone selling you an expensive piece of equipment and checks for quality and production that has a direct impact on your construction timeline has little knowledge beyond pushing the up or down button.

The person you are speaking to on the phone is not who you think it is when it comes to real world experience. They maybe elevator babies!

The good news is that there is an alternative to going to the nursery for elevator and modular advice and information. This is important to know as modular elevators are the future of construction.

MEM (Modular Elevator Manufacturing) is that knowledgeable alternative that has been producing elevators longer than any current modular elevator company and measures their experience in decades, not months. They have been there, done that time and time again when it comes to construction, modular building and elevators.

If you have gotten a quote from another company…give them a call before it is too late or if you have any questions about the benefits of modular elevators or how modular can make your life easier, I would recommend that you contact Hugo Beltran hbeltran@tlshield.com at MEM. You can also get started on your project by clicking Fast Track Quote. They are a company with experience that can give an honest, fair assessment of your needs.

Babies, especially my granddaughter, should be in the arms of someone that loves them, not on the phone dolling out sage advice about elevators like they are all wise through experience that does not exist.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.