“Elevator” and “delays” are two words you should never read in a headline. But in Abilene, Texas that is exactly what happened. The editors of the Abilene Reporter News were a little more creative than most by declaring, the school was “hoping to avoid the shaft” but you get the drift. Unfortunately, elevators delaying construction is far too common across the nation yet wholly unnecessary. There are more modern approaches to elevator installation that eliminate costly delays. You just have to avoid out of date construction methods.

The news article clearly points out why the elevator industry is moving past onsite installation. Schools like Austin Elementary deserve a better process.

People now realize that placing the elevator installation last in the process is fraught with problems and potential delays. This is precisely what happened in this Texas school. The timeline of the project had to be altered.

In this particular case all the other construction was generally completed with minor touch ups and landscaping left to go.

Then the elevator company decided to order the various parts and pieces. Seemingly the crates of components were delayed somehow. But, with the elevator installation at the end of the build, delayed ordering is only one possible stumbling block. There are several potential pitfalls that must be avoided to keep the project on time.

Just as likely a delay can be caused by damaged materials, crates being sent to the wrong address or missing parts. Not to mention materials being damaged during the elevator installation process itself. This can easily happen because onsite installation means that everything in an elevator shaft has to be carried in one piece at a time and then screwed, coerced, and cobbled together.

This all happens in a tight and crowded shaft. It makes no sense at all to do it that way, but that is the process.

Because some of the parts, like rails, are extremely heavy a dropped one can damage more sensitive components. Keep in mind damage does and will occur during the installation. Parts will be broken. It is just a question of if the parts can be easily replaced or hidden from view. That is not to mention all the injuries that can occur due to the manual lifting involved, falling or getting stuck between the various panels and the walls of the shaft. This bogs the crew down.

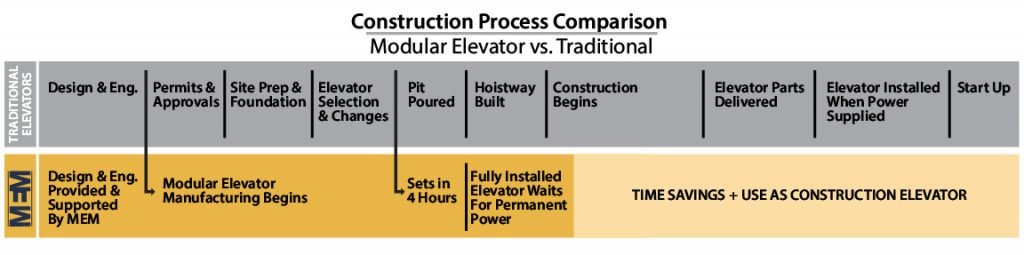

The solution is to have a more up to date installation processes in a factory setting. Then the elevator could be set in place first, avoiding any possible delays. This also cuts the timeline for the entire project. You can see the difference in the chart below. It lays out the difference between the traditional elevator process in gray. And the MEM elevator process in gold.

As you can see it is better to install in a factory, with no heavy lifting and all the parts are readily available. When the project manager wants it the elevator arrives. In less than four hours a fully installed elevator is in place.

Also, if you desire it can be used as a construction elevator.

This process produces higher-quality elevators with factory production that allows for consistent quality control and inspections. The improved process is simply faster, greener and smarter.

Lastly, old-fashioned elevator companies haven’t changed their process since the Civil War. It is that outdated, dangerous and often causes costly construction delays.

Our system has been revolutionizing the elevator industry for over 20 years with a success rate of 100% and hundreds of units in operation. So, the superintendent was mistaken when he said “There are only two companies in the world who do elevators”. Now an educational facility, commercial property, medical facility, parking garage or housing unit can have a fully installed commercial quality elevator delivered when they want. Options are no longer limited.

If you are the least bit curious about our elevators and have a low to mid-rise project in mind, click the Fast Track button for a thumbnail budget number. If you want to explore more, schedule a Live Virtual Tour of our facility. We will show you how we manufacture a high-quality elevator that sets in four hours and starts up in a week.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.