It is a tough chore deciding on what kind of elevator conveyance you should have in your next building project. As I have said before the elevator industry is very secretive about many aspect of vertical transportation. The wrong elevator is often placed in buildings because the information is guarded so closely. Too many resources can be spent on the improper type of elevator conveyance, not to mention the ongoing cost of maintenance and other factors if a bad fit is chosen. I hope to illuminate just some aspects of that decision in this blog, but let me warn you. Elevators are complex so I can’t cover everything in just one sitting. This will be a continuing series with this being the just the first.

Let’s start with the basics. There are three types of elevator conveyance systems (ways the elevator moves). This is regardless of the cab size or capacity of a commercial quality elevator. I am purposely excluding home elevators from this discussion, however there is a lot of transferable knowledge so stick with me. Any cab or weight capacity can utilize any of the three modes of movement. Those three are traction, hydraulic and roped hydraulic.

Traction is the type of conveyance that most people imagine when they think about elevators. It is the one from the movies with the ropes that people are constantly dangling from. Though the term “ropes” can be a little misleading. Here we go again with the elevator industry using terms that can confuse. Ropes are not what cowpokes use to lasso cattle or magicians use to tie up all too willing assistants. Ropes are actually cables. Elevator professionals understand ropes as highly engineered strands of wire wrapped together. A typical cable or rope can have over 150 strands of wire designed to be strong and flexible for a long time.

Ropes fill the hoistway of a traction elevator. That is because although one rope and pulley could in theory lift an elevator car, it would be inefficient and unsafe. So, in the hoistway you will find several hoisting ropes attached to the car and the counter weights. If you were paying attention in sixth grade science class and learned about pulleys and multiplication of force, you know why. Ropes are also redundant for safety.

Then there is a governor rope used to stop the car if there is a failure. If the elevator starts traveling too fast, the governor rope’s movement tells the brakes to stop the car. Lastly there are compensating ropes. Ropes can get heavy (up to 1.85 pounds per foot). Compensating ropes are attached to the car and counterweights to make up for the weight difference. All these ropes and sheaves (really pulley wheels) raise and lower the car.

However, despite appearing with Bruce Willis, Keanu Reeves and Spiderman (see the link at the end for a fun video on elevators in movies) traction elevators may be a star but, is not the the most common type of elevator conveyance. This is due to the attributes that make this type of elevator more conducive to taller buildings. As there are more low-rise or short buildings than high-rise buildings, hydraulic is much more common.

Hydraulic elevators are simply one or two hydraulic jacks pushing the elevator car up in the hoistway and then releasing hydraulic fluid to allow it to move down.

The jacks can either be in-ground or above-ground, depending on how high you need the elevator to go. But think about what a hydraulic jack is. In simplest terms it is a cylinder with a piston inside. As you push hydraulic fluid in, the piston goes up. So if you want to move something up ten feet you have to have a piston at least that tall. This means the whole jack must be at least that tall as well. Hence the in-ground jack.

An in-ground jack configuration is a single jack usually attached directly to the bottom of the elevator car. So to increase the height the car can travel, a taller jack must be used and must then be placed in a hole. The travel distance of the elevator dictates the depth of the hole.

Above-ground jacks (as you can tell by the name) are not in a hole. They are usually two jacks at the bottom of the elevator pit (the area at the bottom of the shaft) and attached above the car on either side, or more properly attached to the car’s sling several feet above the car itself on stiles. Logically, the higher the travel distance – the taller the jacks – the higher above the car the jacks must be attached – the taller the hoistway must be to accommodate the system. You may want to re-read that again. I wrote it and had to peruse it several times to make sure it was right.

In any case, to reduce the need of a real deep hole or a real tall hoistway, jacks can be and often are telescopic. Elevators can typically have up to four-stage telescopic jacks. This ultimately increases the useful range of hydraulic elevators overall.

Lastly, roped hydraulic elevators borrow from both systems. Again keeping it simple, this system of elevator conveyance uses hydraulic jacks, not to push the elevator car up directly, but to push an elevator sheave or pulley up that then with ropes raises the car.

How does it work? It has a pulley wheel or sheave mounted at the top of the piston or pistons and instead of it being directly connected to the bottom of the car or above the car on the sling. The sheave goes up or down as the jack is raised or lowered. A rope goes over the sheave and then is anchored to the hoistway below the lowest level of the piston and to the car.

There are clear benefits to this type of elevator, the most important being the 2:1 ratio of car to jack movement created by the use of sheaves and ropes. This provides a greater range of travel and allows for a shorter jack. Because shorter jacks are used greater travel distances can be achieved without an in-ground jack with its associated drilling costs. Also the travel speed is faster than hydraulic elevator at 200+ feet per minute, but the travel distance can easily be over 80 feet as the ropes and sheaves double the effective length of the jacks.

Your head maybe spinning a bit, especially if you generally view elevators as an annoyance that should be avoided at all costs. But, the above can help you start getting a picture of what type of elevator conveyance should be used in a project based on total travel. And let’s face it, cost and travel are the primary factors. Other factors may include speed, design flexibility and even building codes, but nothing can disqualify an elevator type faster than the practical inability for the elevator to travel the needed distance.

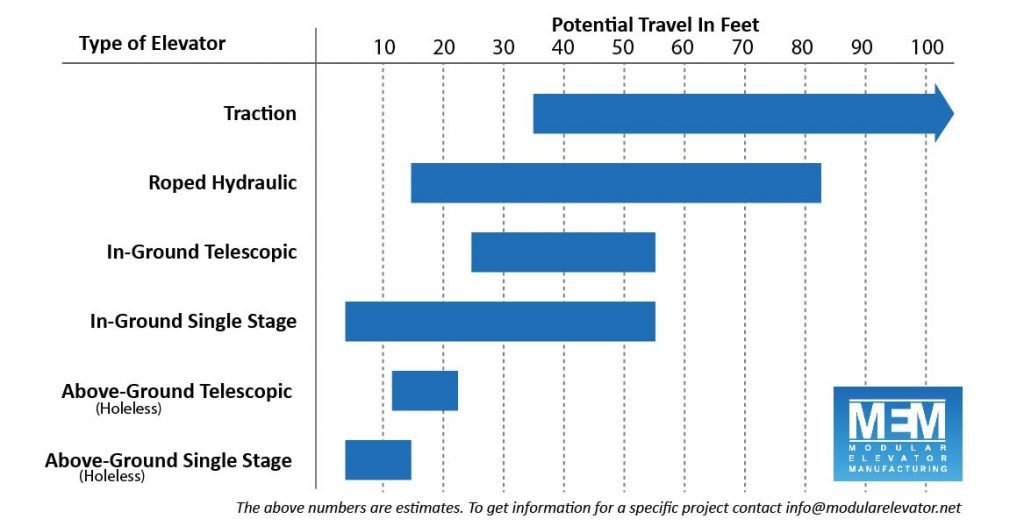

Regarding the cost briefly there are several factors to consider. The initial investment, work space interruption, the value of taking the elevator off the critical path, maintenance contracts and even operating costs. We will explore each of these in future posts, but again to keep it simple. Traction elevators are far and away the most expensive to buy and maintain. Roped hydraulic is next and finally the workhorse of the industry hydraulic is the least expensive. You must however, consider overall travel capabilities when deciding on your elevator. Take a look at the chart below.

The chart is for general guidelines. But as you can see the right elevator conveyance choice starts to take shape. For instance, for a two or three stop elevator, traction can be used but is highly impractical. There is simply no valid benefit for a traction elevator at that height. Likewise, an above-ground or holeless hydraulic elevator maybe less expensive, but impractical terms the limit is less than 30 feet. Also keep in mind that just because you can, does not mean you should. There are massive in-ground single stage hydraulic jacks. But, at the upper end it can get expensive, not only for the jack, but for drilling to nearly China.

So with all that said, hopefully you have a better understanding of the various ways an elevator moves and can start making clearer decisions on which should be employed in your next project whether you use Modular Elevator Manufacturing or not. If you would like a deeper conversation about what would be the best for your project, give us a call or get a fast track number by clicking the button below. We are looking forward to speaking with you.

By the way here is that fun video about the movies and elevators I promised click here.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.

Pingback: ELEVATOR 101 - Modular Elevator Manufacturing