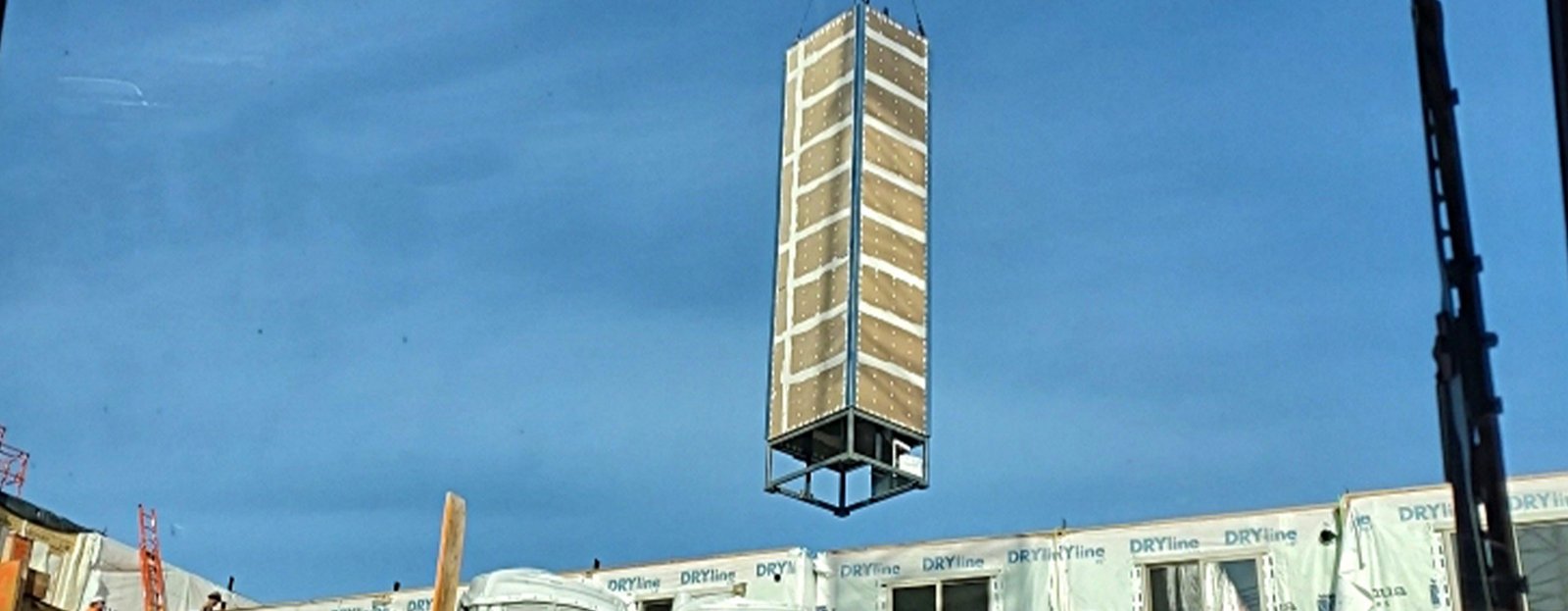

When we say quality at Modular Elevator Manufacturing, it is not just empty words or a marketing ploy. We really mean it and we wished that everyone would take it as seriously as we do. Like you, we have heard the horror story from a project with a different company where, while the elevator was hovering over the building, an elevator jack literally fell out and plummeted into the pit. It could have killed someone.

The story is shocking and absolutely true. People were in danger. Beyond that when a company puts out a product so poorly built it not only potential can harm people on the job-site it can also harm the modular elevator industry and the modular industry as a whole. We all suffer the black-eye, when quality is not just suspect, but dangerous. But MEM is different and here’s how.

To start with MEM has just been at it longer. We didn’t just pop up out of no where with no construction or elevator experience. Our track record is clear with over 40 years experience in the building industry and a 20 year manufacturing track record of success and safety. We have never – never had anything like the scare of a 300 pound jack falling from the sky. Our installs go in smoothly because we have so much more experience in the elevator industry as a result we are not guessing, but we know how things should go.

MEM elevators are also engineered with safety in mind. Usually when you say safety and elevators you are talking about for the riding public and our elevators are very safe; we never put the general public at risk. But we have engineered our products so they are also safe to install as well. One of the many plusses of the modular industry is that it means safety on the job-site. The heavy lifting and working in cramped quarters is eliminated when the process is moved to the factory. There are plenty of cranes, lifts and working space on the factory floor. Plus there is no working at heights while the shaft is being built like in traditional construction. If poor engineering or lack of care causes components to fall out of a hoistway the benefit of modular goes away. That is why we care about safety and the manufacturing process.

With MEM we understand how important work site safety is and engineer that into each and every elevator we produce. It may take more effort, higher-grade materials and more care when building them, but MEM elevators are built for safety before, during, and after the set and start up.

Lastly, we check every product we manufacture with our one-of-a-kind 10 Point Inspection by a certified elevator technician. Before the elevator is loaded on the truck, we make sure of the following:

Each of the above is a part of a process that produces consistent quality. But, keep in mind that having a is great but, the most important aspect at MEM is that a certified elevator technician is doing the checking and not just any old employee. We have multiple employees that are qualified and capable of checking everything out. We simply cannot vouch for what others are doing, but rest assured we do our best to make sure the elevator you get is the highest quality.

Lastly, we want to assure everyone that despite poor quality from some, modular is the safest and best way to build. Whether you are considering the method for an entire building or wanting to retrofit an existing structure with a safe, fast installing modular elevator, reputable companies in the modular building industry are ready to build faster, greener and most importantly safer.

If you are curious about modular elevators and have a project in mind that you would like a quote for, click the button below. If you want to know more details about the accident that has caused such a stir, contact me at your convenience. I am always more than happy to explain why modular is the best solution and MEM is always quality elevators taking you to a higher level.

When we say safe, quality Modular Elevators it is not just empty words or a marketing ploy. We really mean it and we wished that everyone would take it as seriously as we do. Like you, there are rumors from the past of a project with a different company where, while the elevator was hovering over the building, an elevator jack literally fell out and plummeted into the pit. It could have killed someone.

The story is shocking and absolutely true. People were in danger. Beyond that when a company puts out a product so poorly built it not only potential can harm people on the job-site it can also harm the modular elevator industry and the modular industry as a whole. A safe quality modular elevator is always our goal and we accomplish that goal. But, we all suffer the black-eye, when quality is not just suspect, but dangerous. MEM is different and here’s how.

To start with MEM has just been at it longer. We didn’t just pop up out of no where with no construction or elevator experience. We have over 40 years in the building industry and a 20 year manufacturing track record of success and safety. We have never – never had anything like the scare of a 300 pound jack falling from the sky. Our installs go in smoothly because we have so much more experience.

MEM elevators are also engineered with safety in mind. Usually when you say safety and elevators you are talking about for the riding public and our elevators are very safe, never putting the general public at risk. But we have engineered our products so they are also safe to install as well. Part of the many pluses of the modular industry is that it means safety on the job-site. The heavy lifting and working in cramped quarters is moved to the factory with plenty of cranes and space on the factory floor. Plus there is no working at heights while the shaft is being built like in traditional construction.

With MEM we understand how important work site safety is and engineer that into each and every elevator we produce. It may take more effort, higher-grade materials and more care when building them, but MEM elevators are built for safety before, during and after the set and start up.

Lastly, we check every product we manufacture assuring safe, quality modular elevators with our one-of-a-kind 10 Point Inspection by a certified elevator technician. Before the elevator is loaded on the truck, we make sure of the following:

Each of the above is a part of a process that produces consistent quality. If you are not careful you could pick the wrong modular company (the one where the jack fell out). Keep in mind that it is important that it is a certified elevator technician doing the checking and not just any old employee. We have multiple employees that are qualified and capable of checking everything out. We simply cannot vouch for what others are doing, but rest assured we do our best to make sure the elevator you get is the highest quality.

Lastly, we want to assure everyone that modular is the safest and best way to build. It is tested. tried and true and takes advantage of the latest building principles. Whether you are considering the method for an entire building or wanting to retrofit an existing structure with a safe, fast installing modular elevator, reputable companies in the modular building industry are ready to build faster, greener and most importantly safer.

If you are curious about safe, quality modular elevators and have a project in mind that you would like a quote for, click the button below. If you want to know more details about the accident that has caused such a stir, contact me at your convenience. I am always more than happy to explain why modular is the best solution and MEM is always quality elevators taking you to a higher level.

Affordable Housing – Modular Elevator Solution. No one can deny right now there is a problem for urban areas of all sizes and that is affordable housing. According to the most recent stats from “The State of Homelessness in America” a publication of the Council of Economic Advisors, a half-million Americans struggle with housing. 65% of that half-million can be found in homeless shelters while an astonishing 35% or nearly 200,000 are on the streets.

But, I really didn’t need to give you the stats. A stroll down the street in many of our cities reveals the problem without reading a detailed report. Homelessness abounds.

At its core the issue is one of supply and demand. Simply put, there just are not enough residences for a myriad of reasons. As a result the law of supply and demand dictate that many of the homeless are so, because they are priced out of the market. There are just too few housing options. The supply is low – the demand is high and that makes prices likewise high.

One solution is to reform the laws and codes in local jurisdictions that have helped create the problem. Unsurprisingly, the report lays blame at that door and maybe deservedly so. But, good luck with sweeping legislative change, let alone sweeping change fast.

The current political climate in most urban areas makes wholesale changing of housing laws for the better a pipe dream. With that reality it makes the only other solution increasing the supply of affordable housing. The alternative is turning a blind-eye to the problem or to burry our collective heads in the sand.

If more units are the best solution a couple of hurdles need to be crossed. Both time and space need addressing. I am not taking about Albert Einstein and the theory of relativity. Where (space) the housing units can be placed and how fast (time) they can be erected is the concern. This is an immediate crisis and one that will not go away without action so, the faster new housing can be readied for occupancy, the better.

When it comes to housing where it is placed is always key. I recently toured neighborhoods where two completed affordable housing units where ready for occupancy. During the tour I noticed that surrounding the new modular buildings were rows of houses and small apartment complexes. They lined the street, crammed closely together. The houses were probably built in the 40’s or 50’s and most of the houses were still occupied. Several showed a high level of pride in home ownership. As a result it would be unrealistic to acquire those properties in bulk to create a new, sprawling complex. It would be costly and inefficient.

I did however, notice two or three dilapidated units, usually grouped in clusters. There were no rose bushes or neatly trimmed lawns. Graffiti was more common than a car in the drive. They were obviously abandoned. So more housing could be more easily accomplished to use those small narrow lots, instead of buying and bulldozing dozens. But, solving this problem takes more than just a new house being built in place of the old. Multiple units would have to go in that space. That means building up. In the two units I toured it meant a modular elevator.

The second you say “elevator” in any project that is time sensitive eyes roll. Everyone knows that traditional, old-fashioned elevator installation wrecks the timeline for completion. Tacking an additional 6-months, a year or more to the completion date is not unheard of. So, building an affordable housing unit with a traditional elevator is not addressing the immediate need at all. It certainly doesn’t show the homeless population much compassion for the plight they are in, especially when there are alternatives.

Modular building is a much faster option. In the two examples I visited both were purely modular. However, a modular elevator can be used in any type or building project. Even retrofit applications can have a modular elevator installed.

The time savings is because the elevator being built as a completed unit in the factory while the project is still in the process of site prep and permitting. They are then delivered to the jobsite as finished elevators.

Modular elevator units from Modular Elevator Manufacturing can even be used as a construction elevator as they are delivered when you want them.

The elevator is placed in less than four hours and when power is provided they are started up in less than a week. The elevator is removed from the critical path. Problem solved.

Time and space has been inextricably combined by Albert Einstein. His theory linked both into one entity. The same is true with the housing crisis we face.

Time and space are huge obstacles that are linked in the quest for affordable housing. Modular elevators are the solution to addressing both problems at once. The space available means to address the housing crisis we are forced to build up in multi-story units. However, concerns over time constraints and the need to act quickly have dampened the enthusiasm for a multi-story solution. Modular elevators put that solution back on the table. It has worked successfully already in a number of projects we have been a part of.

We are ready to discuss a vertical transportation solution for any low or mid-rise project. Hopefully, we can be a part alleviating the issue of homelessness. Affordable housing is an immediate need and we can be part of the solution. To get the process started just click on the button below. We can provide you with a quote in less than a day.

“The elevator holds everything up!” that is a common complaint among those in the modular building industry. Modular companies are growing by leaps and bounds. However, finding a way to incorporate vertical transportation quickly and smoothly was always a sticking point.

It is true that modular building is the future. It just makes sense as it means a high-quality project completed in a greener and safer way. But one of the biggest selling points with modular is the speed in which the project can be completed. Typically when you place traditional construction on a timeline there are gaps. After the permits and financing is set, the ground has to be prepped. Then the foundation is poured and infrastructure for the building brought in. Months tick by.

Meanwhile, despite the project being totally ready to go, the building makes it no further. There it sits as plans on a drawing board until the site is completely ready. Modular takes all of the waiting out of the process. The building can begin as the site is being prepped. In that way when the location is ready, modular units are ready to be immediately swung into place. It is estimated that modular building can reduce time significantly. This is because construction of the modular components can occur simultaneously with the site and foundation work. This means projects can be completed 30% to 50% sooner than traditional construction.

The modular process does speed things up incredibly fast, but there has been a huge fly in the ointment. The elevator. Despite advances in modular building, the elevator was mired in old-fashioned construction practices. Or the companies that built modular elevators were so low in quality that headaches outweighed any benefits of speed. Dangerous product were even being distributed. A new nationwide solution had to be created for the modular industry.

The results is MEM and we are increasing distribution to the whole nation. Now from New York to California and Florida to Alaska there is a true quality solution. A solution that is reliable and fast to set and start up.

As an example, realizing the need for speed and quality, MEM was called on a multi-family housing unit. It was completed on time and on budget with quality elevators. The builder’s experience had dictated that a conventional elevator NEVER gets the elevator done on time. But, they called MEM and got a taste of what we can do. Now they will never go back to any other way.

Soon modular builders will start using MEM nationwide and the complaint about the elevator holding up the project will disappear. It will be just like the solution we provided above and there will be no turning back from the quality and speed we provide.

If you have a project in mind and you are ready to try out a modular elevator, click the link below and we can give you budget numbers in a day. To fill out the Fast Track quote we just need a little simple information to get you started on a fast – safe – quality solution.

Quality Elevators – When we say quality at Modular Elevator Manufacturing, it is not just empty words or a marketing ploy. We really mean it and we wished that everyone would take it as seriously as we do. Like you, we have heard the horror story from a project with a different company where, while the elevator was hovering over the building, an elevator jack literally fell out and plummeted into the pit. It could have killed someone.

The story is shocking and absolutely true. People were in danger. Beyond that when a company puts out a product so poorly built it not only potential can harm people on the job-site it can also harm the modular elevator industry and the modular industry as a whole. We all suffer the black-eye, when quality is not just suspect, but dangerous. But MEM is different and here’s how.

To start with MEM has just been at it longer. We didn’t just pop up out of no where with no construction or elevator experience. We have over 40 years in the building industry and a 20 year manufacturing track record of success and safety. We have never – never had anything like the scare of a 300 pound jack falling from the sky. Our installs go in smoothly because we have so much more experience.

MEM elevators are also engineered with safety in mind. Usually when you say safety and elevators you are talking about for the riding public and our elevators are very safe, never putting the general public at risk. But we have engineered our products so they are also safe to install as well. Part of the many pluses of the modular industry is that it means safety on the job-site. The heavy lifting and working in cramped quarters is moved to the factory with plenty of cranes and space on the factory floor. Plus there is no working at heights while the shaft is being built like in traditional construction. If huge elevator components are falling out of a hoistway that plus of job-site safety goes away.

With MEM we understand how important work site safety is and engineer that into each and every elevator we produce. It may take more effort, higher-grade materials and more care when building them, but MEM elevators are built for safety before, during and after the set and start up.

Lastly, we check every product we manufacture with our one-of-a-kind 10 Point Inspection by a certified elevator technician. Before the elevator is loaded on the truck, we make sure of the following:

Each of the above is a part of a process that produces consistent quality. If you are not careful you could pick the wrong modular company (the one where the jack fell out). Keep in mind that it is important that it is a certified elevator technician doing the checking and not just any old employee. We have multiple employees that are qualified and capable of checking everything out. We simply cannot vouch for what others are doing, but rest assured we do our best to make sure the elevator you get is the highest quality.

Lastly, we want to assure everyone that despite the most recent debacle, modular is the safest and best way to build. Whether you are considering the method for an entire building or wanting to retrofit an existing structure with a safe, fast installing modular elevator, reputable companies in the modular building industry are ready to build faster, greener and most importantly safer.

If you are curious about modular elevators and have a project in mind that you would like a quote for, click the button below. If you want to know more details about the accident that has caused such a stir, contact me at your convenience. I am always more than happy to explain why modular is the best solution and MEM is always quality elevators taking you to a higher level.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.