MEM Elevator – Walk Through Wonder / RAD Technology Medical Systems worked with the Palomar Health team and Mascari Warner Dinh Architects for a spectacular design. It is a 6,700 sq ft, custom 2-story OSHPD approved CSU addition. The plan included the MEM Elevator System that you can see in a 3D Walk-Through RAD posted.

In addition the unique design for the expansion, the walk-through clearly shows the modular elevator. It was designed to include a complete stainless-steel package. It gives the building a clean, professional look Palomar Health was looking for.

Also, this project is proof positive that speed to completion does not have to impede great design. Some may think a fast timeline can be detrimental to the overall aesthetics of the building. However, based on the final look, feel, and quality, we see that is not true. One would not know that the project was assembled and ready for occupancy in less than 8 months.

Craig Braund, MEM Systems expert with TLShield and Associates says this was a perfect fit. “Anytime you need speed and quality combined in a project that contains a low to mid-rise elevator, the MEM Elevator System is the best option.” He went on to say that working with the professionals at RAD, Palomar and Mascari Warner Dihn was a pleasure. “Too often in the construction industry people don’t understand how all the various components work in concert with each other. The finished Palomar project shows precisely how everything should work together.”

So, from Modular Elevator Manufacturing and the MEM Elevator System, congratulation for a fantastic project. To RAD Technology, Palomar Health and the architecture firm Mascari Warner Dinh Architects thank you for including us!

Now you can act. If you are impressed with the project, the MEM Elevator System, and a bit curious contact us. We can provide you a walk through wonder like the one featured in the 3D rendering. We provide two great ways to find out more.

If you have a project in mind and think we would be a solution click the Fast Track Quote button below. Fill out as much as you know on the form. We will contact you with in 24 hours to fill in any blanks and let you know a thumbnail number. We also believe in transparency, so we offer a great opportunity to schedule a live virtual factory tour. Just click the button and request a date.

“Elevator” and “delays” are two words you should never read in a headline. But in Abilene, Texas that is exactly what happened. The editors of the Abilene Reporter News were a little more creative than most by declaring, the school was “hoping to avoid the shaft” but you get the drift. Unfortunately, elevators delaying construction is far too common across the nation yet wholly unnecessary. There are more modern approaches to elevator installation that eliminate costly delays. You just have to avoid out of date construction methods.

The news article clearly points out why the elevator industry is moving past onsite installation. Schools like Austin Elementary deserve a better process.

People now realize that placing the elevator installation last in the process is fraught with problems and potential delays. This is precisely what happened in this Texas school. The timeline of the project had to be altered.

In this particular case all the other construction was generally completed with minor touch ups and landscaping left to go.

Then the elevator company decided to order the various parts and pieces. Seemingly the crates of components were delayed somehow. But, with the elevator installation at the end of the build, delayed ordering is only one possible stumbling block. There are several potential pitfalls that must be avoided to keep the project on time.

Just as likely a delay can be caused by damaged materials, crates being sent to the wrong address or missing parts. Not to mention materials being damaged during the elevator installation process itself. This can easily happen because onsite installation means that everything in an elevator shaft has to be carried in one piece at a time and then screwed, coerced, and cobbled together.

This all happens in a tight and crowded shaft. It makes no sense at all to do it that way, but that is the process.

Because some of the parts, like rails, are extremely heavy a dropped one can damage more sensitive components. Keep in mind damage does and will occur during the installation. Parts will be broken. It is just a question of if the parts can be easily replaced or hidden from view. That is not to mention all the injuries that can occur due to the manual lifting involved, falling or getting stuck between the various panels and the walls of the shaft. This bogs the crew down.

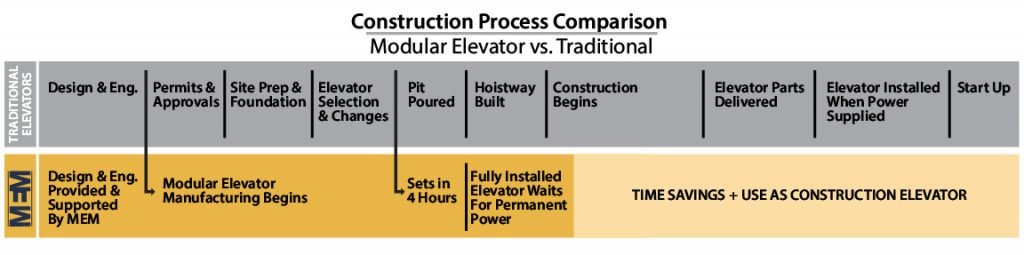

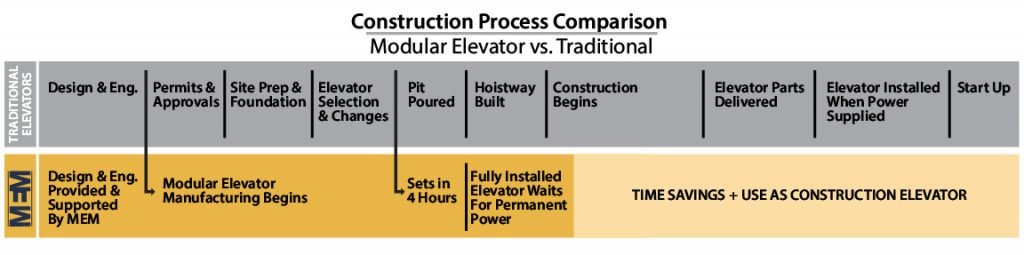

The solution is to have a more up to date installation processes in a factory setting. Then the elevator could be set in place first, avoiding any possible delays. This also cuts the timeline for the entire project. You can see the difference in the chart below. It lays out the difference between the traditional elevator process in gray. And the MEM elevator process in gold.

As you can see it is better to install in a factory, with no heavy lifting and all the parts are readily available. When the project manager wants it the elevator arrives. In less than four hours a fully installed elevator is in place.

Also, if you desire it can be used as a construction elevator.

This process produces higher-quality elevators with factory production that allows for consistent quality control and inspections. The improved process is simply faster, greener and smarter.

Lastly, old-fashioned elevator companies haven’t changed their process since the Civil War. It is that outdated, dangerous and often causes costly construction delays.

Our system has been revolutionizing the elevator industry for over 20 years with a success rate of 100% and hundreds of units in operation. So, the superintendent was mistaken when he said “There are only two companies in the world who do elevators”. Now an educational facility, commercial property, medical facility, parking garage or housing unit can have a fully installed commercial quality elevator delivered when they want. Options are no longer limited.

If you are the least bit curious about our elevators and have a low to mid-rise project in mind, click the Fast Track button for a thumbnail budget number. If you want to explore more, schedule a Live Virtual Tour of our facility. We will show you how we manufacture a high-quality elevator that sets in four hours and starts up in a week.

A free elevator is a dream for many. Let’s face it, elevators are generally expensive if you want a good one. However, if you sharpen your pencil and your perspective you can find vertical transportation that provides enough savings to make even the highest quality elevator significantly less expensive.

But, to start the hunt for a free elevator you have to begin with a question. What in real terms makes up a commercial quality elevator that you find in any building project?

Well, in most basic terms it has to have an elevator car, rails for the car to ride up and down on and a hoistway the rails are attached to. That skeleton then has to have a heart. The heart is the conveyance system that makes the car raise and lower as well as open and close the doors at each floor. After that, to carry the analogy further, it needs skin. A great looking interior to the car with lights, buttons, hall calls and handrails. The hoistway can also be part of the skin in the form of a glass elevator and decorative finish or just a painted surface. That is what an elevator is in its essence.

There are two processes to accomplish the above:

The differences in the finished product of the two elevators are negligible (other than quality) as most of the component come from the very same supplier companies regardless of the process. Whether you are buying a modular elevator or have an elevator installed onsite each has the same pieces or the components have been through the same rigorous approval process. These two systems produce generally the same elevator.

So if the products are largely the same and roughly the same cost, how do you get one for free with modular, but not traditional?

The answer is found in the savings that you can obtain because of the modular nature of the MEM elevator. The chart below explains the process for both. The traditional elevator is significantly different by the nature of how they are installed. They take much longer to cobble together on your jobsite when they want. There is design and engineering, followed by permits and approvals, site prep and the foundation and inevitable changes. Finally when the pit is poured and construction begins, the traditional elevator company lurches into motion.

They order parts and make sure logistically all the pieces and tools are dumped on your site with you contractually responsible. Then they start the installation process most usually after power is turned on.

MEM (the gold row) on the other hand arrives when you want. It takes the design and engineering that we have partnered together on and begins manufacturing. By the time the pit is poured the fully installed elevator is ready to be set in place. That takes about four hours (no kidding). As unbelievable as it may seem, you have a fully installed elevator sitting onsite waiting for power. Then when you are ready to have a fully functioning elevator turned on, we make sure it is started up properly. It is really that simple.

The traditional or old-fashioned way of putting in an elevator is at the end of the construction process. This throttles the completion and this is not idle speculation.

A thesis and study put forward by the Penn State College of Engineering supports this contention. In an actual parking garage construction sequence of a five-story project it was found that the elevators took a crazy 58 days to complete. Also, they were the last trade to get started other than landscaping and parking lot striping. They were also the last trade to finish. Now imagine changing that number of 58 days to ten, putting the elevators in first and using it as a construction lift like we did at San Jose State.

The date the parking garage opens comes sooner as the job closes faster. This reduces overall costs in addition to other benefits. No more making space for storage of all of the parts and pieces. Big sections of projects are cordoned off for this purpose. That slows the project. Not to mention all the coming and going with a big carbon footprint. Also they are burning your electricity to install the elevator. MEM’s elevator comes pre-installed.

Lastly, with a modular elevator once power is on and adjustments are made, you can use it as a construction elevator.

So now sharpen your pencil and put a dollar sign beside each item listed below. How much is it worth that:

As you can see with the above list and a sharp pencil you can save ten of thousands of dollars or more by using MEM elevators on every low and mid-rise project. The general conditions alone can run tens of thousands per month. So when you balance the costs and savings, you can have a higher-quality elevator installed when you want for less.

Is the elevator really free? Nope, but the savings you will gain using an MEM elevator will often be more than your investment. Not to mention the faster occupancy rate that has as an additional benefit. I was once thanked for trimming months off a project putting more money in the investor’s pocket on a hotel project.

So summing it all up isn’t it time to at least consider a modular elevator for your next project? To get the ball rolling all you have to do is click the Fast Track button below. The form asks a few easy questions and then we will contact you with an obligation-free budget number. If you want to do a little more research join a Live Virtual Tour of our facility to see how we produce the highest quality commercial elevator that installs in hours. Just click that button to get on the schedule.

Speedy Multifamily Elevator Solution. One of the ways that young Americans have influenced the construction industry is that lately they have been prone to delay home purchases. This can be attributed to many factors including high prices for home ownership, a lack of the needed down payment and a delay in marriage and family. So, when they do leave their parent’s basement, generally they are renting in large numbers and not looking for the white picket fence.

The result is in many medium and large municipalities there is a predictable shortage of rental units and ultimately price inflation. Hence the multifamily building boom.

Governing.com demonstrates this through statistical data. They report that between the year 2000 and April of 2019 there was, “a median increase in the renter population of 31 percent…Over the same period, the number of owner-occupied dwellings also rose, but only by a median of 7 percent.”

That means building multifamily units is needed and needed fast. That need is further demonstrated by the recent number of multifamily unit starts as the market moves to fill demand.

According to Dodge Data & Analytics residential starts as a category only increased by 2% in July of 2020. That sounds pretty bad for business until you dive more into the numbers. Of those new starts multifamily units increased by a whopping 11%, while single family units (homes) showed an overall decline. Multifamily units are booming even in a tough Covid filled economy.

The above statements and stats are known in the industry, so what is the big deal? The big deal is that in a competitive market, speed to that market becomes extremely important. You want to be building on the upswing and not at the top when units get tough to fill. So any edge you can find to decrease the time of project completion the better. That speed is crucial as the fight to fill the void in housing becomes a race. The race will either be won or lost by various builders and design build firms.

Keep in mind that the race now includes not just general apartment complexes or condominiums. They are also a wide range of market specific dwelling spaces. Subcategories such as senior living, low income or non-traditional mixed use building projects are on an upward trajectory.

One of the time saving mechanisms was addressed on a conference call I attended with design build industry leaders. We were discussing the concept and current acceptance of modular as the solution to the speed of delivery dilemma. A participant, Patrick Kennedy of Panoramic Interests downplayed the diversification of the market, and maintained the time to build could be significantly reduced if they stuck to three types of building plans that could easily fit burgeoning subcategories. He said they have three plans, “Hamburger, cheese burger and deluxe.”

Depending on who, why and where the units were to be built, the basic plans all fell into those three types of designs. Then depending on what specifically was requested, the spaces use could be altered, just not the overall plans. That kind of consolidation of offerings is very wise and makes perfect sense when building faster and more efficiently is a priority as it is today. Faster is better and they found a great way to speed things up. But that example is not the only edge available.

In car racing whether it is NASCAR, Formula 1 or a soapbox derby speed is important. But, it is the small things that are done, sometimes months before we hear, “Drivers start your engines!” that are key. To create the success and speed on the track a lot must happen, as a simple turn of a bolt on the chassis setup could be the difference between the checked flag and as Dale Earnhardt would say being the “first loser”.

So if finishing a building project quickly is important (and we all know that it is) then finding even small ways to speed up the building process is crucial. Using simplified plans, as discussed, is one way to achieve that speed. But so is placing in those plans a time saving modular elevator. One of the biggest complaints we hear about the elevator industry is that with traditional installation the whole project becomes bogged down. It is slow and laborious. But, what if all of that installation can take place in a factory, rain or shine and the elevator can be delivered and fully installed in a day or less, on the day of your choosing? That is a game changer.

Reality Check It is also a reality and not some fiction or dream of the future. So now it is time for a “reality check” in the form of a few questions:

So here’s the thing with the speedy multifamily elevator solution. If you are honest you can see the time and financial benefits of a quality, commercial modular elevator. And honestly chances are your competitors already have seen the benefits. We know this because as the multifamily market continues to heat up, we have doubled our sales and had to double our factory space and capacity to keep up.

If you would like to have a discussion just call us or email and ask anything you want. We will always be straightforward and honest as we have been in the modular elevator business longer than anyone else, with more experience and have a record of integrity and quality. We have installed five times more elevators than all of our competitors combined.

So, if you have project in mind just click the Fast Track button below. Just a few questions and we can have a thumbnail quote to you in a day. The opportunity is there for the checkered flag; take it with the help of Modular Elevator Manufacturing and a speedy multifamily elevator solution.

Never miss a blog post again. Sign up for our monthly email newletter. Get important information about elevators, the modular industry and more.